Preparation method of a 150°C high flame retardant radiation crosslinked low smoke halogen-free cable material

A cable material and high flame-retardant technology, which is applied in the field of preparation of high flame-retardant radiation cross-linked low-smoke halogen-free cable material at 150°C, can solve the problems of reducing the mechanical and electrical properties of the material, material aging, degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

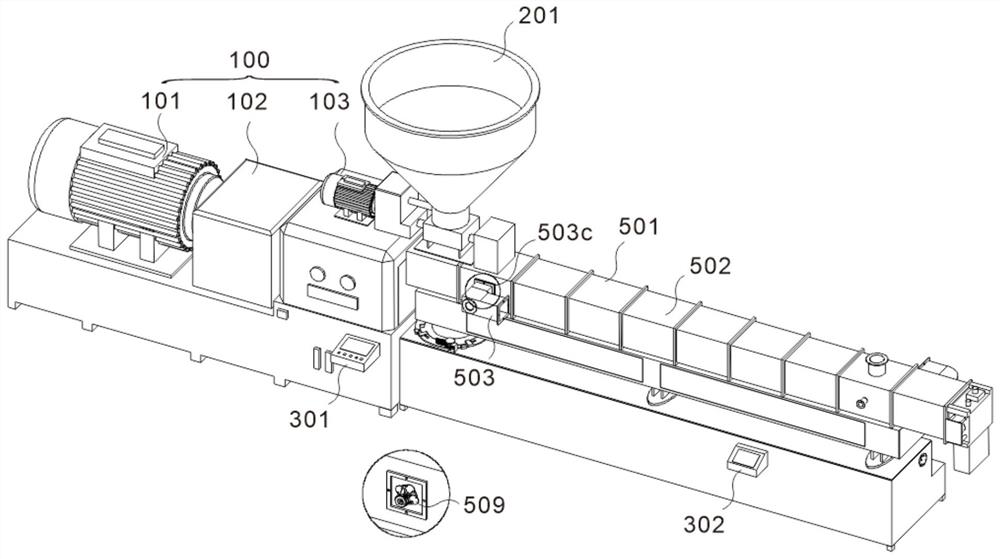

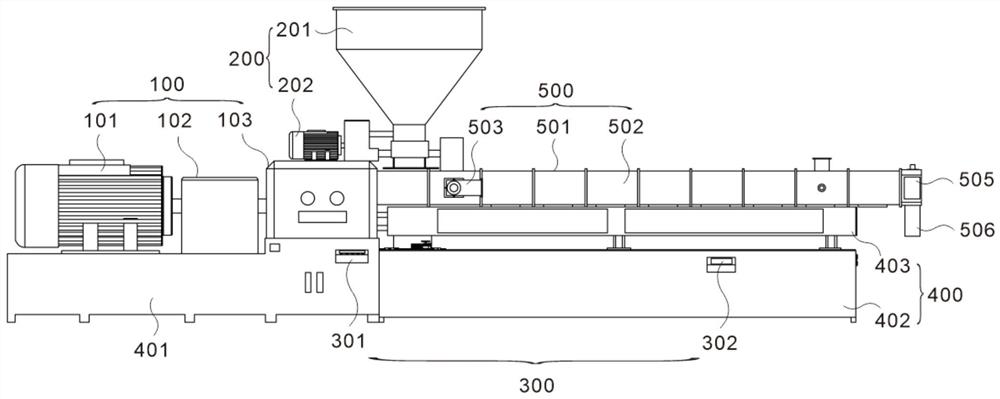

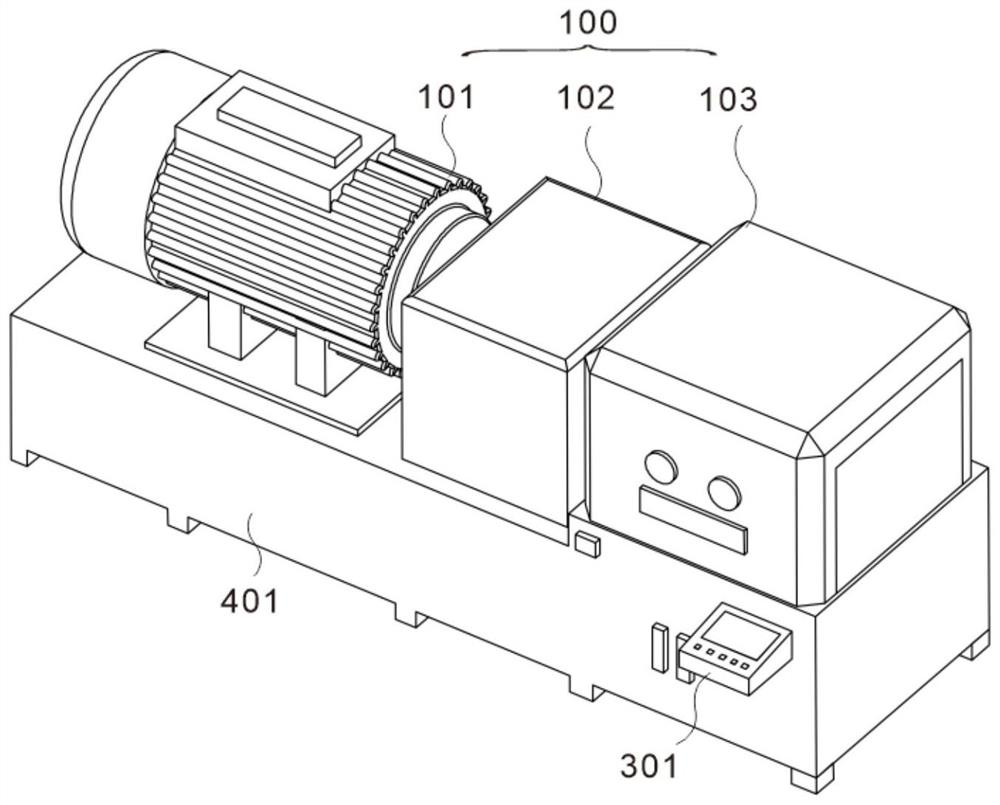

Image

Examples

Embodiment 1

[0038] A 150°C high flame retardant radiation cross-linked low-smoke halogen-free cable material, in terms of mass percentage, the components and the content of each component are: 22% ethylene-vinyl acetate copolymer, 8% polyethylene, DOPO 38%, TAIC 18%, inorganic flame retardant 13%, initiator 0.7%, and antioxidant additive 0.3%. The sum of the mass percentages of each component is 100%.

[0039] Among them, the melt index of ethylene-vinyl acetate copolymer is 3.2g / 10min, the density of polyethylene is 0.906g / cm3, and the melt index is 3.0g / 10min; the purity of DOPO is 97%, the purity of TAIC is 96%, and the inorganic flame retardant It is aluminum hydroxide; the initiator is DCP with a purity of 96.3%; the antioxidant additive is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, N,N' -Bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine and N,N"'-1,2-ethanediylbis[N-[3-[4,6 -Di[butyl(1,2,2,6,6-pentamethyl-4-piperidinyl)amino]-1,3,5...

Embodiment 2

[0063] A 150°C high flame retardant radiation cross-linked low-smoke halogen-free cable material, in terms of mass percentage, the components and the content of each component are: ethylene-vinyl acetate copolymer 26.5%, polyethylene 10%, DOPO 39%, TAIC 20%, inorganic flame retardant 2%, initiator 2%, and antioxidant additive 0.5%. The sum of the mass percentages of each component is 100%.

[0064] Among them, the melt index of ethylene-vinyl acetate copolymer is 3.2g / 10min, the density of polyethylene is 0.906g / cm3, and the melt index is 3.0g / 10min; the purity of DOPO is 97%, the purity of TAIC is 96%, and the inorganic flame retardant It is aluminum hydroxide; the initiator is DCP with a purity of 96.3%; the antioxidant additive is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, N,N' -Bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine and N,N"'-1,2-ethanediylbis[N-[3-[4,6 -Di[butyl(1,2,2,6,6-pentamethyl-4-piperidinyl)amino]-1,3,5...

Embodiment 3

[0088] A 150°C high flame retardant radiation cross-linked low-smoke halogen-free cable material, in terms of mass percentage, the components and the content of each component are: ethylene-vinyl acetate copolymer 27%, polyethylene 13%, DOPO 35%, TAIC 16%, inorganic flame retardant 7%, initiator 1.5%, and antioxidant additive 0.5%. The sum of the mass percentages of each component is 100%.

[0089] Among them, the melt index of ethylene-vinyl acetate copolymer is 3.2g / 10min, and the density of polyethylene is 0.906g / cm 3 , the melt index is 3.0g / 10min; DOPO purity 97%, TAIC purity 97%, inorganic flame retardant is aluminum hydroxide; Initiator is DCP, and purity is 96.3%; Antioxidant auxiliary agent is four [β-(3, 5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, N,N'-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine and N ,N"'-1,2-ethanediylbis[N-[3-[4,6-bis[butyl(1,2,2,6,6-pentamethyl-4-piperidinyl)amino ]-1,3,5-triazin-2-yl]amino]propyl]-N,N"-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com