A kind of preparation method of high damping constant Mooney viscosity natural rubber and the product thereof

A natural rubber and constant Mooney technology, which is applied in the field of high damping constant Mooney viscosity natural rubber and its preparation, can solve problems such as failure, mechanical property damage, damping performance decline, etc., and achieve easy addition, small change in Mooney viscosity, The effect of high equivalent damping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

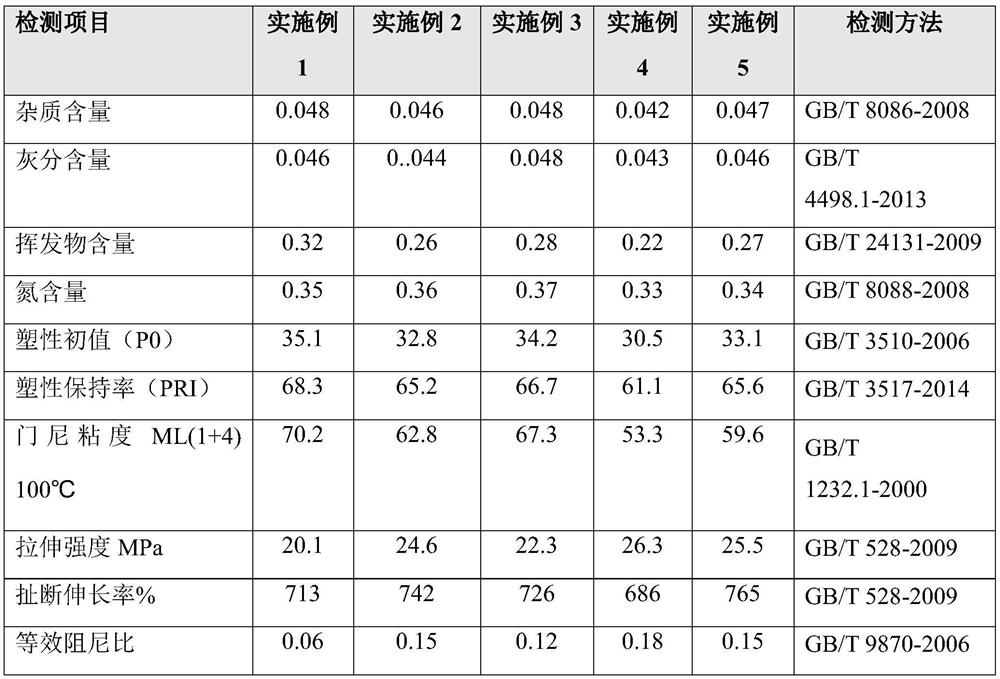

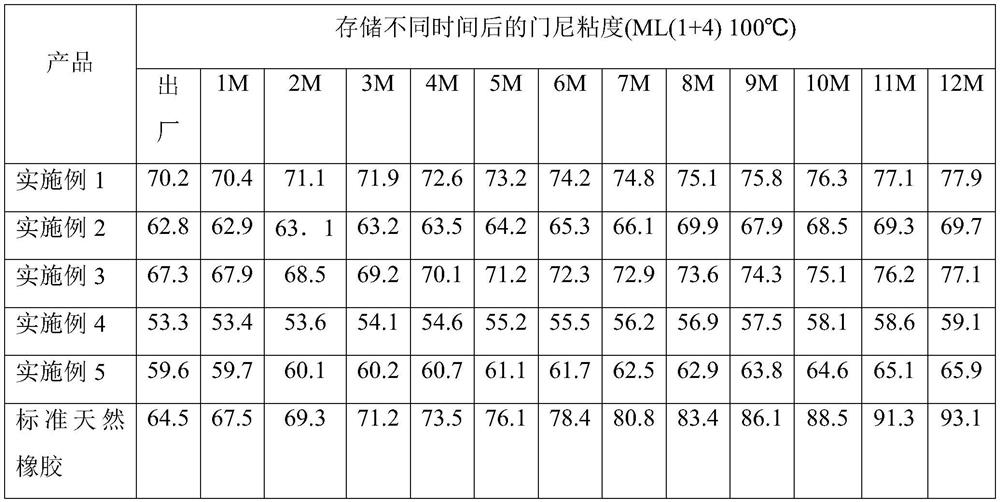

Examples

Embodiment 1

[0028] Crush the wrinkled sheet glue, rinse the impurities, dry it, and weigh it for later use.

[0029] Weigh the constant viscosity hydrazine ethanol according to 5‰ of the weight of the crepe glue, then add it together with the crepe glue into a dry mixer and mix, and stir for 4 minutes.

[0030] Then, through cooling, briquetting and other processes, the constant Mooney viscosity natural rubber is obtained.

Embodiment 2

[0032] Carry out according to the process described in Example 1, but before adding the constant viscosity agent hydrazine ethanol, weigh the maleic anhydride-modified polystyrene according to 10% of the weight of the crepe glue, and put it in a dry mixer together with the crepe glue. It was stirred for 4 minutes in the medium and then treated with the constant viscosity hydrazinoethanol.

Embodiment 3

[0034] Crush the wrinkled sheet glue, rinse the impurities, dry it, and weigh it for later use.

[0035] The maleic anhydride-modified polystyrene was weighed according to 5% of the crepe glue weight, and stirred together with the crepe glue in a dry mixer for 3 minutes.

[0036] Then, 2‰ of the weight of the crepe glue was sprayed into the dry mixer with the constant viscosity agent hydrazine-based ethanol, and the mixing was continued for 3 minutes.

[0037] Then, through the processes of cooling and briquetting, the natural rubber with high damping constant Mooney viscosity is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com