Cold-proof material for subway carriages and preparation process of cold-proof material

A preparation process and a technology for carriages, which are used in metal processing, adhesives, film/flake adhesives, etc., can solve the problems of poor thermal insulation effect of cold-proof materials, and achieve excellent thermal insulation effect and good thermal insulation. Effective, hygienic and safe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

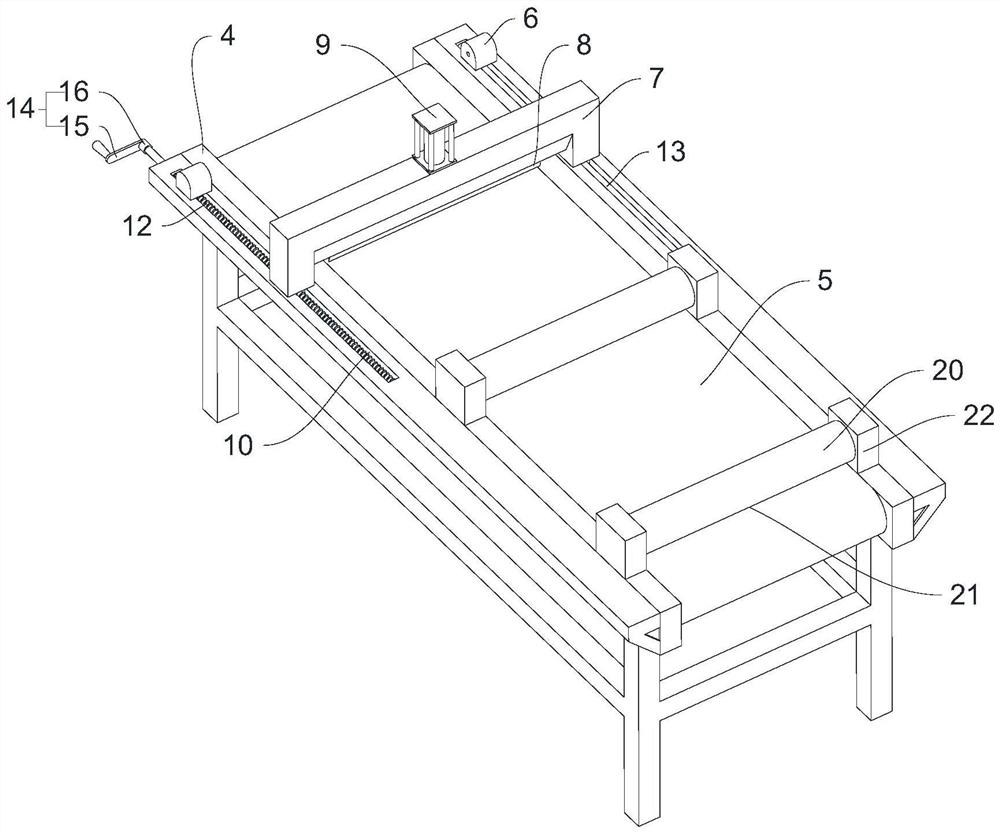

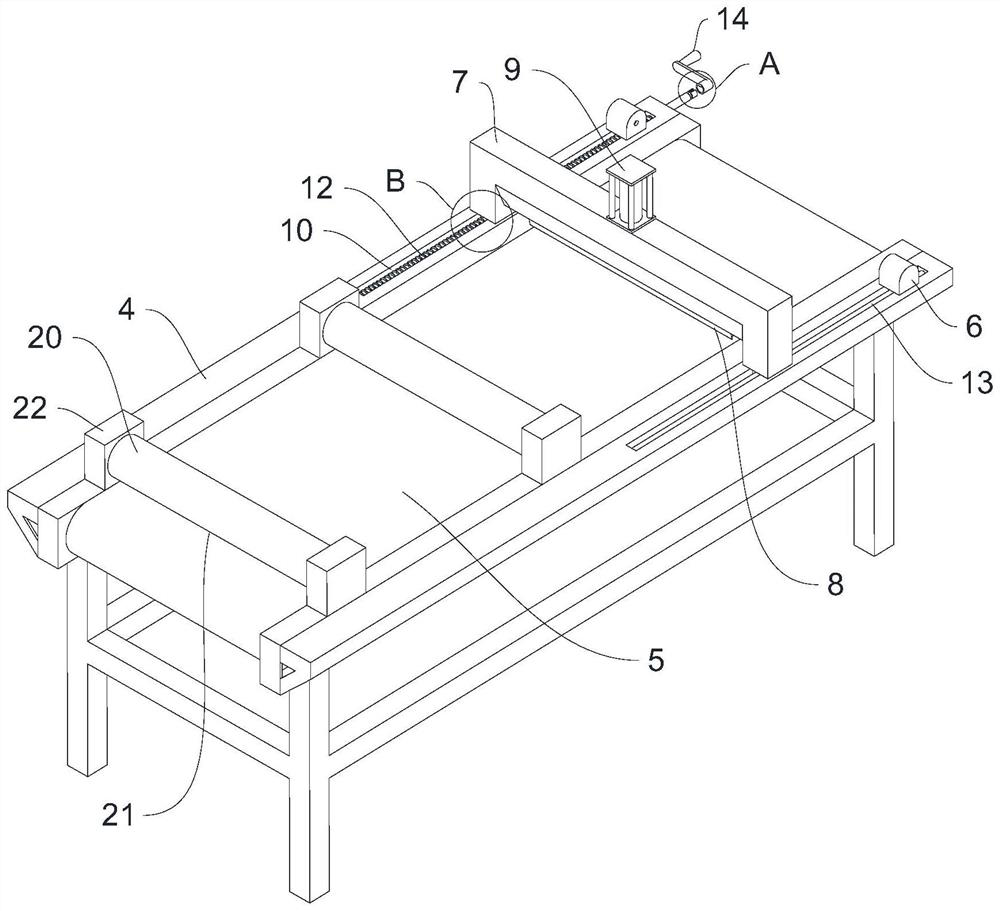

[0035] In order to easily understand the technical means, creation features, achievement goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

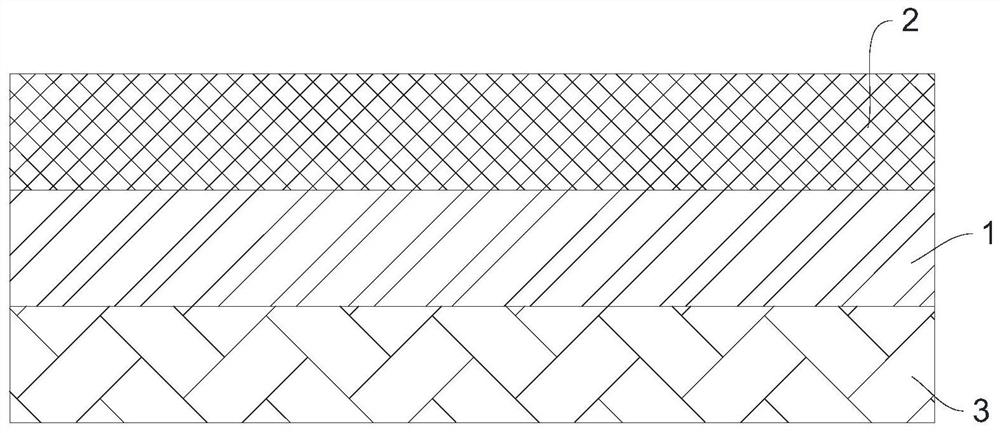

[0036] like figure 1 As shown, a cold-proof material for a subway car includes a cold-proof base layer 1, and an insulating layer 2 and an adhesive layer 3 are respectively hot-pressed and laminated on both sides of the cold-proof base layer 1. The heat-insulating layer 2 is made of aluminum foil, and the cold-proof base layer 1 is made of foam. Finished melamine cotton.

[0037] Because the cold-proof material is made of a cold-proof base layer 1, an insulating layer 2 and an adhesive layer 3, wherein the heat-insulating layer 2 is made of aluminum foil, and the cold-proof base layer 1 is made of foamed melamine cotton, and the aluminum foil has excellent thermal insulation. Thermal effect, melamine cotton has excellent sound absorption, flame retard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com