Energy-saving and environment-friendly bran steaming equipment and bran steaming method

An energy-saving, environmental-friendly and equipment-friendly technology, which is applied in the field of wine making, can solve problems such as ineffective removal of miscellaneous odors, ineffective use of water vapor, and influence on steam output efficiency, so as to improve steam utilization, facilitate installation, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

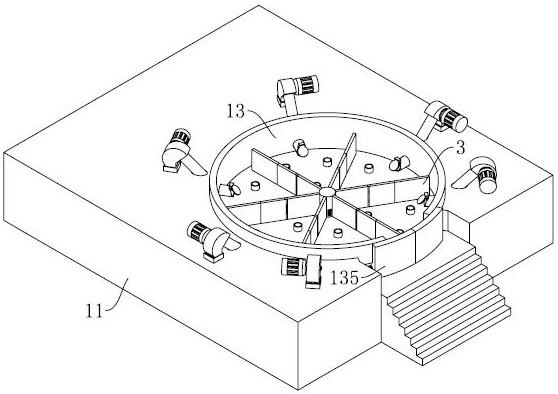

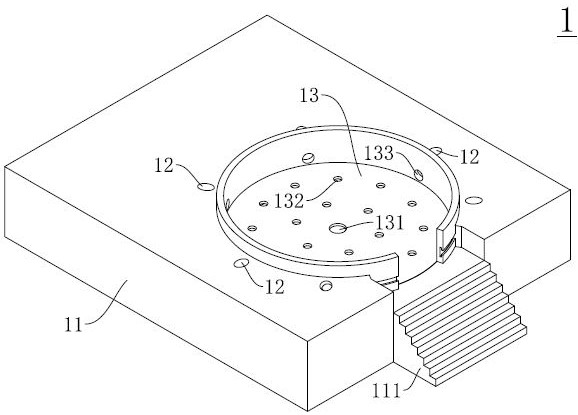

[0044] like Figure 1~Figure 13 The energy-saving and environment-friendly bran steaming equipment shown includes a shell unit 1 , a blowing unit 2 , a separation unit 3 , and a bran steaming unit 4 .

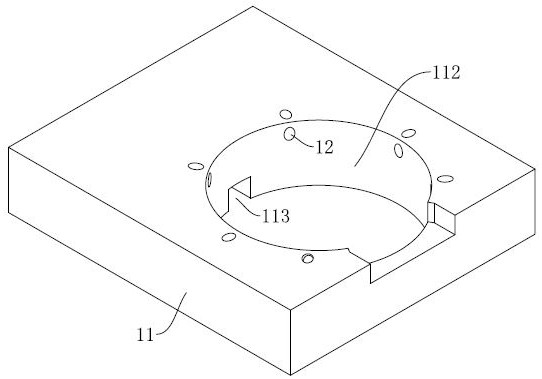

[0045] The shell unit 1 includes a bran steaming chamber 11, one end of the bran steaming chamber 11 is provided with a staircase 111, the other end is provided with a pipe groove 113, the upper end surface of the bran steaming chamber 11 is provided with a pool groove 112, and the steaming bran chamber 11 is also provided with six inclined Channel 12, one end of the inclined channel 12 is opened on the upper end face of the bran steaming chamber 11, the other end is opened on the side wall of the tank 112, one end of the pipe groove 113 is opened on the side wall of the tank 112, and the other end is opened in the bran steaming chamber 11. At one end, the steam pool 13 with a diameter of 5m to 10m is arranged in the pool groove 112, and has a predetermined distance from the bo...

Embodiment 2

[0052] Adopt the energy-saving and environment-friendly steaming bran method of the energy-saving and environment-friendly steaming bran equipment of embodiment 1, and operate according to the following steps:

[0053] S01: close the sliding door 135 to seal the opening, install the bran steaming tank with the same diameter as the steam tank 13 on the upper end of the steam tank 13 by driving, and add the bran shell into the bran steaming tank;

[0054] S02: Pass steam into the main steam pipe 41, most of the steam is input to the steam pool 13 through the steam port 431, and a small part of the steam passes through the main steam pipe 41, the connecting pipe 411, the cavity of the central column 31, and the air groove 311 to the steam pool in turn. Input 13, the total steam flow is 12 m³ / min~20 m³ / min, start the power supply of the blower 22 at the same time, blow air into the steam pool 13 through the stainless steel ventilation inclined pipe 23, provide the power to move the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com