Flexible guide piece, flexible guide mechanism and flexible guide device

A technology of flexible guiding mechanism and guiding parts, which is applied in the direction of measuring devices, mechanical equipment, force/torque/work measuring instruments, etc., which can solve the problems of large vibration, easy bending, and small bending stiffness, so as to achieve force balance and prevent Effect of eccentric vibration and high bending rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

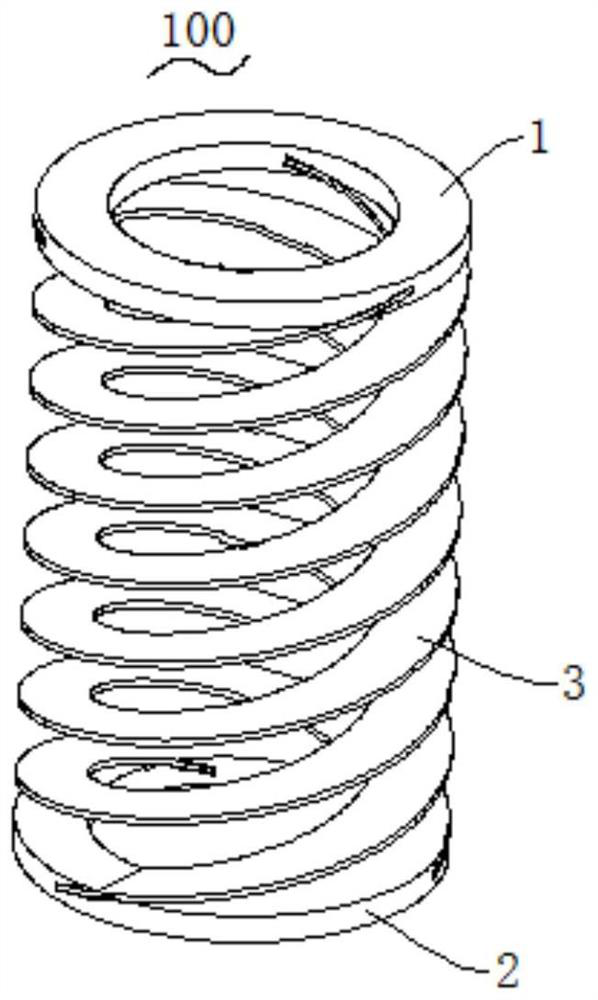

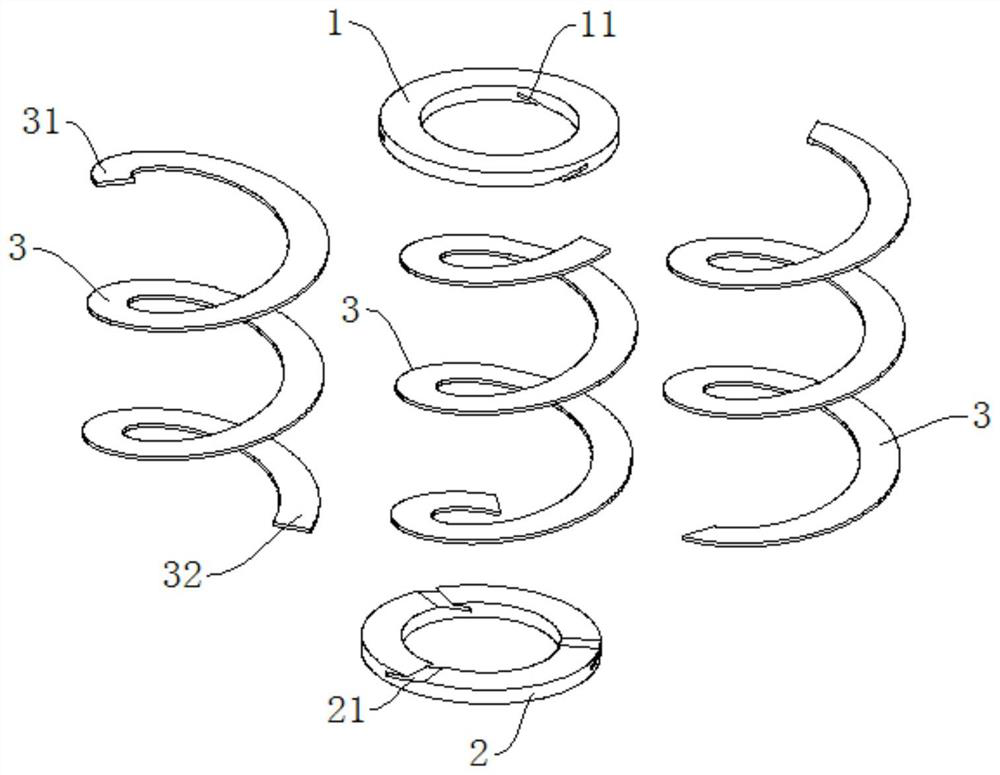

[0036] combine Figure 1 to Figure 2 As shown, this embodiment provides a flexible guide member, and the flexible guide member is provided with a plurality of spiral bodies 3 between the first fixed seat 1 and the second fixed seat 2. Each helix 3 is composed of helixes 3 of the same structure. The inner diameter, outer diameter, pitch, helix direction and other structural parameters of the three helixes 3 are the same. During installation, the three helixes 3 can be superimposed coaxially together. That is, the three helical central axes of the three helical bodies 3 are coaxially arranged, and then the three first end heads 31 at one end of the three helical bodies 3 are fastened with the first fixing seat 1, and the three second end heads at the other end are fastened. 32 is fastened with the second fixing seat 2, so as to form such as figure 1 Flexible guide shown.

[0037] Further, in order to make the three spiral bodies 3 evenly bear the load force applied to the firs...

Embodiment 2

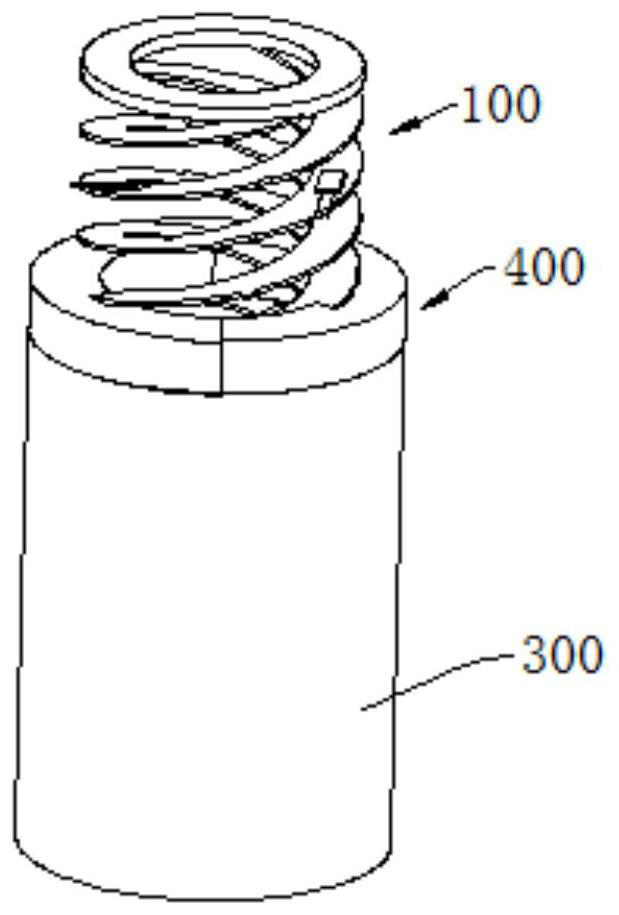

[0043] combine Figure 3 to Figure 7 As shown, this embodiment provides a flexible guide mechanism, the flexible guide mechanism includes the flexible guide member 100 in the above-mentioned embodiment, and the adjustment adjustment that is fastened to the lower end of the flexible guide member 100 and the lower bottom surface of the second fixed seat 2 The seat 200, the adjustment sleeve 300 sleeved on the adjustment seat 200 and connected with the adjustment seat 200 in a threaded connection, and an adjustment ring disposed on the upper end of the adjustment sleeve 300 and connected with the flexible guide member 100 in a threaded connection, the adjustment ring 400 and the adjustment sleeve 300 are coaxially tightened. solid.

[0044] Further, due to the influence of the first fixing base 1 and the second fixing base 2 at both ends of the flexible guide member 100, the adjusting ring 400 cannot form a threaded connection with the first fixing base 1 and the second fixing ba...

Embodiment 3

[0047] combine Figure 8 As shown, this embodiment provides a flexible guide device. Since the cross-section of the spiral body 3 of the flexible guide member 100 in the flexible guide device adopts a rectangular cross-section with a high aspect ratio, it can be directly connected to each flexible guide member 100. A strain measurement sensor is installed on the spiral body 3, and then the plurality of strain measurement sensors 500 are electrically connected to the external electronic control device, so as to obtain the force condition of the plurality of flexible guide members 100 in real time, and then calculate the flexible guide through the external electronic control device. The axial moment and bending moment received by the member 100 can further effectively monitor the application of the flexible guide member 100, so that the flexible guide member 100 can play a better guiding and buffering role.

[0048] The specific circuit settings of the external electronic contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com