Low-flow-resistance flange cast steel straight-through stop valve

A low flow resistance, cut-off valve technology, applied to the cut-off valve. It can solve the problems of reducing the flow resistance coefficient of the valve, accelerating the damage of the valve body, shortening the life of the valve disc, etc., and achieve the effects of avoiding pressure damage, reducing scouring, and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

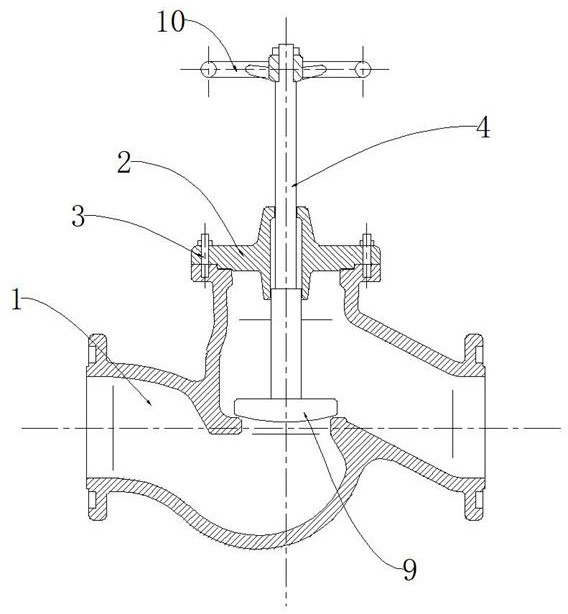

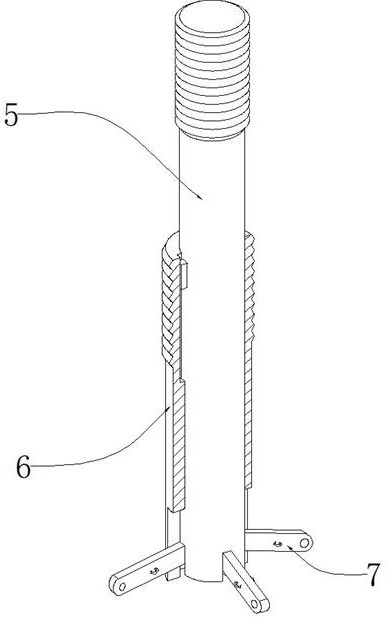

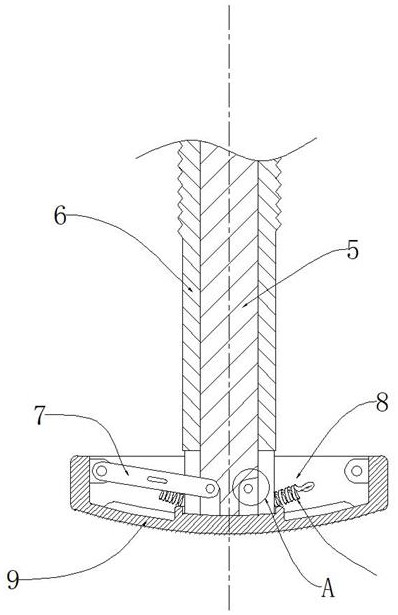

[0030] The present embodiment provides a low flow resistance flanged cast steel straight-through globe valve, which includes a valve body 1. The inlet and outlet of the medium are respectively provided on both sides of the valve body 1, and the upper end of the valve body 1 is fixed by the bonnet screw 3 A valve cover 2 is connected, a valve stem 4 is arranged through the center of the valve cover 2, a handwheel 8 is threadedly fixed on the top of the valve stem 4, and the bottom of the valve stem 4 penetrates into the valve body 1 and is connected with a valve disc 9, which passes through the valve disc. 9. The communication between the medium inlet and the medium outlet on both sides of the valve body 1 is closed. It is characterized in that the valve stem 4 includes an outer screw 6 and an inner screw 5 that can be displaced in the vertical direction when rotating, and the outer screw 6 and the inner screw 5 are respectively connected with The center of the valve disc 9 is c...

Embodiment 2

[0040]A kind of low-flow-resistance flanged cast steel straight-through globe valve provided by the present embodiment is different from the low-flow-resistance flanged cast steel straight-through globe valve in Example 1 in that: when the valve is opened, the lower surface of the valve disc 9 and the valve The inner wall of the upper end of the body 1 is in contact with the inner wall surface, and the inner wall of the upper end of the valve body 1 has an arc surface structure corresponding to the valve disc 9 , and forms an arc surface structure with a uniform arc surface with the lower surface of the valve disc 9 .

[0041] When the technical solution of this embodiment is adopted, when the valve is opened, due to the difference in the pitch of the surface threads of the inner screw 5 and the outer screw 6, the valve disc 9 is urged to bend as a whole to form an upwardly protruding curved surface, and the lower surface of the curved surface is connected to the top of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com