Method for recycling and removing aluminum from waste lithium iron phosphate battery

A lithium iron phosphate battery, waste technology, applied in the direction of waste collector recycling, secondary batteries, chemical instruments and methods, etc., can solve the industry standard that is difficult to reach the content of battery-grade iron and aluminum phosphate, the high price of organic solutions, and the removal of aluminum. Insufficient thoroughness, etc., to achieve the effect of easy industrial application, good aluminum removal effect, and reduction of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

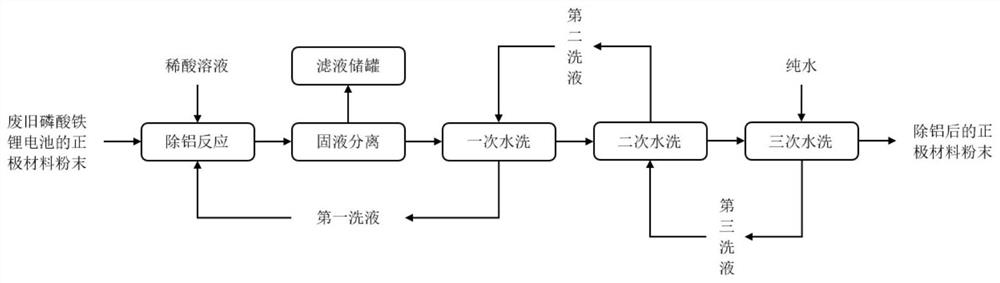

[0030] like figure 1 As shown, the present embodiment provides a method for recycling and removing aluminum from waste and old lithium iron phosphate batteries, the steps comprising:

[0031] S1, the quantitative first washing solution is transported to the aluminum removal reaction device, and the quantitative positive electrode material powder of the waste lithium iron phosphate battery is slowly transferred to the aluminum removal reaction device, and the positive electrode material powder is mixed with the aluminum removal reaction device. The mass ratio of the first washing solution is 1:4. After stirring for 20 minutes, the mixture is fully mixed, and a quantitative dilute sulfuric acid solution (2%) is transported to the aluminum removal reaction device. The dilute sulfuric acid solution and the positive electrode are mixed. The molar ratio of aluminum content in the material powder is 5:1;

[0032] S2, after 60min of aluminum removal reaction at 65°C, the material is ...

Embodiment 2

[0037] The present embodiment provides another method for recycling and removing aluminum from waste and old lithium iron phosphate batteries, and the steps include:

[0038] S1, the quantitative first washing solution is transported to the aluminum removal reaction device, and the quantitative positive electrode material powder of the waste lithium iron phosphate battery is slowly transferred to the aluminum removal reaction device, and the positive electrode material powder is mixed with the aluminum removal reaction device. The mass ratio of the first washing solution is 1:5. After stirring for 10 minutes, the mixture is fully mixed, and a quantitative dilute sulfuric acid solution (3%) is transported to the aluminum removal reaction device. The dilute sulfuric acid solution and the positive electrode are mixed. The molar ratio of aluminum content in the material powder is 5:1;

[0039] S2, after the aluminum removal reaction at 80°C for 30min, the material is transported t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com