Rolling brush self-cleaning device and self-cleaning method

A self-cleaning and cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems affecting the floor cleaning effect, affecting user experience, automatic cleaning, etc., to achieve improvement Floor cleaning effect, improve self-cleaning effect, solve time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] A self-cleaning method for a rolling brush, comprising the following steps: a controller receives a start signal and starts a self-cleaning process;

[0100] The self-cleaning process is used to clean the roller brush, the roller brush scraper and the liquid-spraying channel in the cleaning equipment; the self-cleaning process includes a first reversal step: controlling the roller brush motor to drive the roller brush to rotate in the reverse direction; preset time.

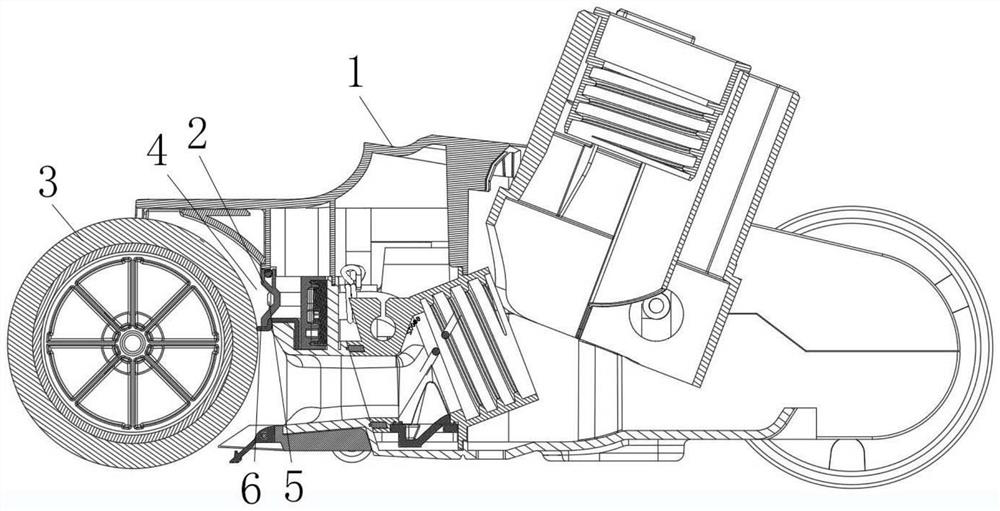

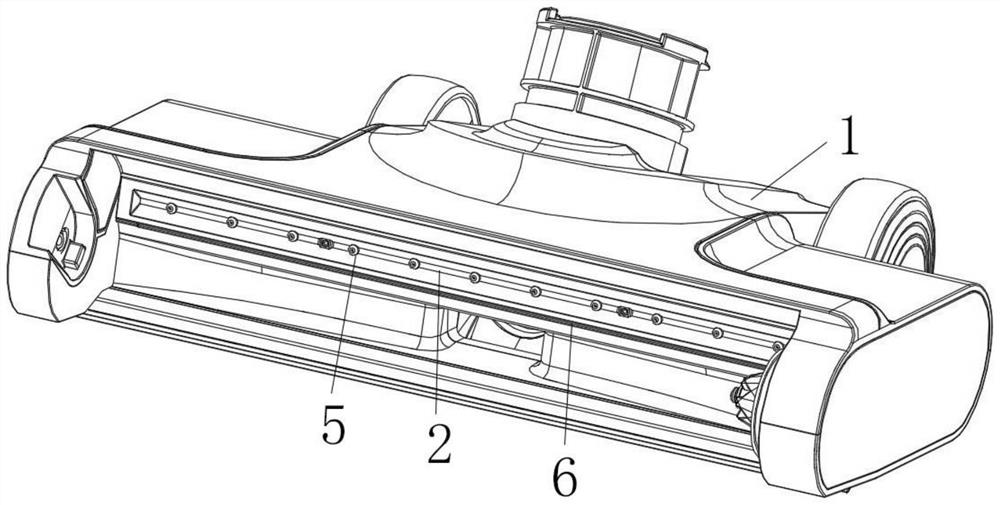

[0101] like figure 1 As mentioned, in this embodiment, the cleaning device is a washing machine; the washing machine includes a controller and a handle connected in sequence, a washing machine body and a floor brush, and a clean water tank is arranged on the washing machine body , main engine motor and sewage tank; the floor brush includes a floor brush main body 1, a liquid spray device 2, a liquid suction pipe, a suction device, a rolling brush motor for controlling the rolling brush, and the rolling br...

Embodiment 2

[0116] This embodiment is carried out on the basis of the above-mentioned first embodiment, and the same points as the above-mentioned embodiment will not be repeated.

[0117] This embodiment mainly introduces a technical solution in the first embodiment: the self-cleaning process includes the following sub-steps:

[0118] The first liquid spraying step: turn on the liquid spraying device, and the liquid spraying device sprays liquid to the roller brush with the first flow rate;

[0119] The first reversing step: controlling the rolling brush motor to drive the rolling brush to rotate in reverse for a first preset time;

[0120] Suction step: Turn on the main engine motor to suck the garbage on the roller brush, the roller brush scraper and the liquid spray channel into the liquid suction device.

[0121] In the above, the first liquid spraying step is mainly responsible for spraying cleaning liquid on the rolling brush, which can wet the rolling brush and clean the rolling ...

Embodiment 3

[0126] This embodiment is carried out on the basis of the above-mentioned first or second embodiment, and the same points as the above-mentioned first or second embodiment will not be repeated.

[0127] Further, the self-cleaning process includes the following sub-steps:

[0128] (1) Turn on the liquid spray device and the rolling brush motor at the same time, the liquid spray device sprays liquid to the rolling brush at a first flow rate, and the rolling brush motor makes the rolling brush reversely rotate for a first preset time;

[0129] (2) Turn on the main engine motor, and suck the garbage on the roller brush, roller brush scraper and liquid spray channel to the liquid suction pipe.

[0130] In the above, the step (1) is that the first liquid spraying step and the first reversing step are performed simultaneously, and the step (2) is the suction step.

[0131] In the above, step (1) is mainly responsible for cleaning the rolling brush. The rolling brush is sprayed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com