Heat treatment process of TC11 titanium alloy casting

A technology of TC11 and titanium alloy, which is applied in the field of new materials, can solve problems such as poor plasticity and difficulty in regulating the casting structure of TC11 titanium alloy, and achieve the effect of improving plasticity and matching mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

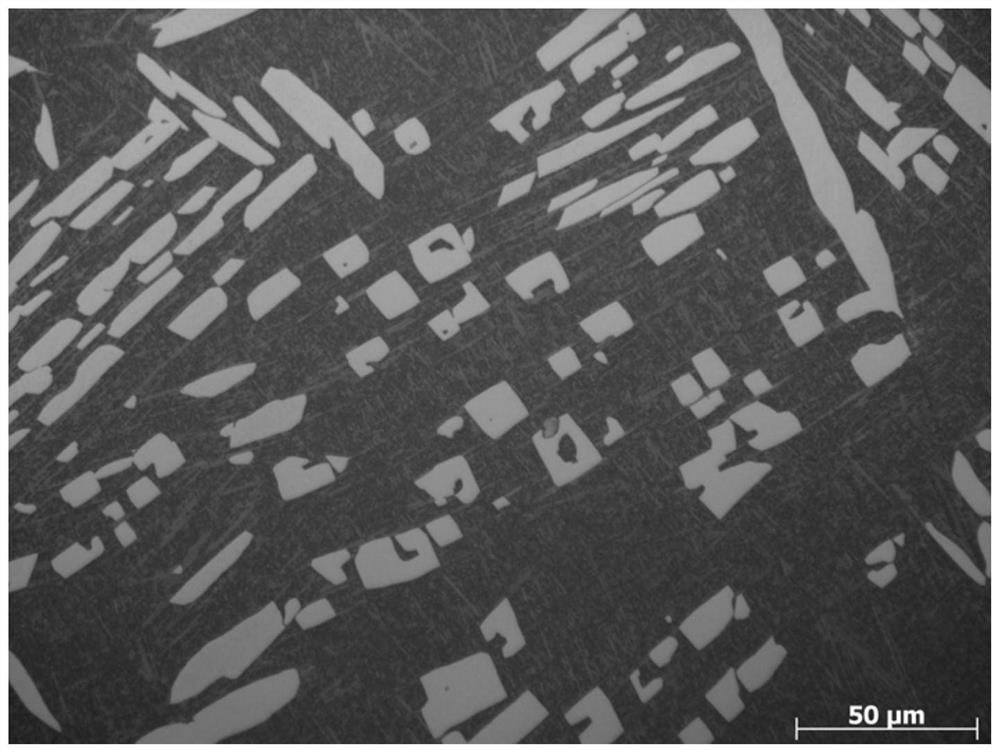

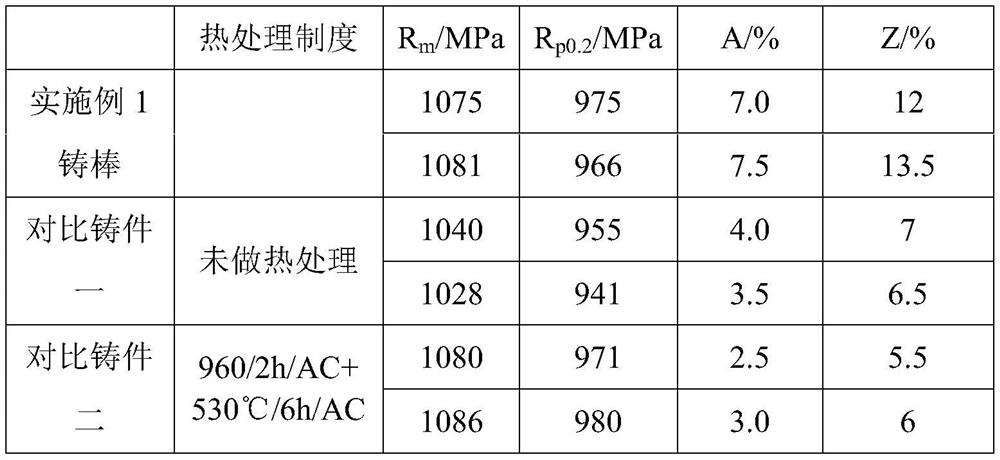

Embodiment 1

[0019] The material used in this example is a TC11 alloy cast rod with a specification of φ25mm×200mm, its composition is Ti-6.6Al-3.5Mo-1.8Zr-0.3Si, and its alloy transformation point is 1021°C;

[0020] 1) First, heat the TC11 cast rod to 1010°C for 60min;

[0021] 2) Cool the cast rod to 1007°C by furnace cooling, and continue to keep the temperature for 60min;

[0022] 3) Continue furnace cooling to 1004°C and hold for 60min; continue furnace cooling to 1001°C and hold for 60min; continue furnace cooling to 998°C and hold for 60min; continue furnace cooling to 995°C and hold for 60min; continue furnace cooling to 992°C and hold 60min; continue furnace cooling to 989°C and hold for 60min; continue furnace cooling to 986°C and hold for 60min; continue furnace cooling to 983°C and hold for 60min; continue furnace cooling to 980°C and hold for 120min; continue furnace cooling to 977°C and hold for 120min; continue The furnace is cooled to 974 ℃ and kept for 120 minutes, and t...

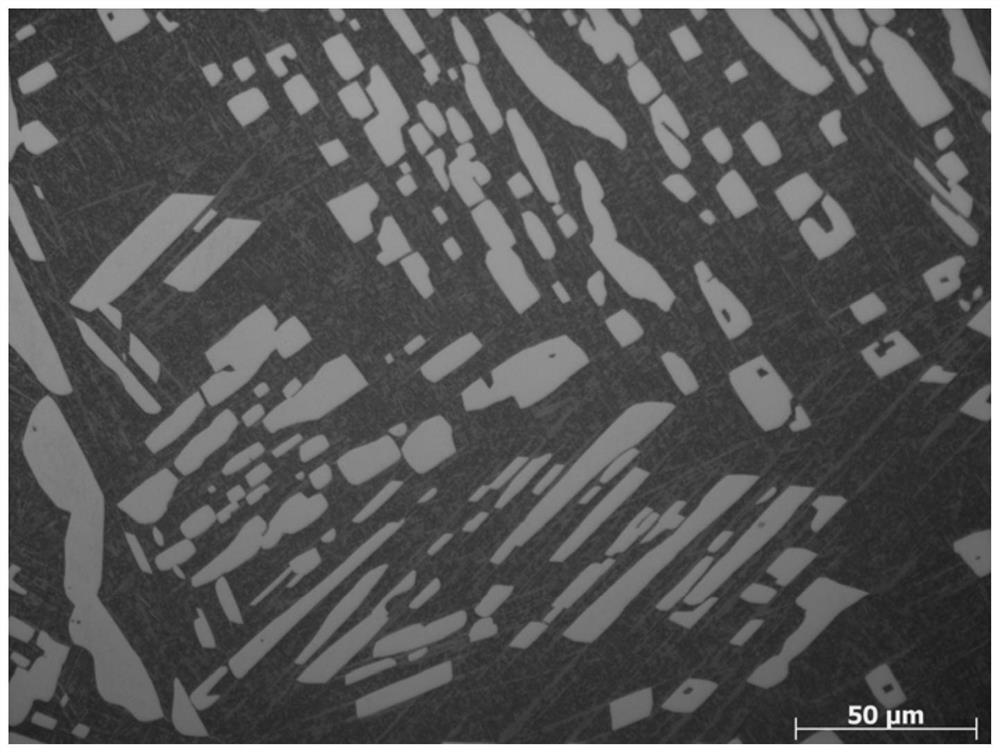

Embodiment 2

[0031] The material used in this example is TC11 casting barrel material with a specification of φ450mm×φ430×600mm, and its alloy transformation point is 1021°C;

[0032] 1) First, heat the TC11 cast rod to 1010°C for 60min;

[0033] 2) Cool the cast rod to 1007°C by furnace cooling, and continue to keep the temperature for 60min;

[0034] 3) Continue furnace cooling to 1004°C and hold for 60min; continue furnace cooling to 1001°C and hold for 60min; continue furnace cooling to 998°C and hold for 60min; continue furnace cooling to 995°C and hold for 60min; continue furnace cooling to 992°C and hold 60min; continue furnace cooling to 989°C and hold for 60min; continue furnace cooling to 986°C and hold for 60min; continue furnace cooling to 983°C and hold for 60min; continue furnace cooling to 980°C and hold for 120min; continue furnace cooling to 977°C and hold for 120min; continue Furnace cooling to 974°C for 120min; continue furnace cooling to 971°C for 120min, then air-cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com