Preparation method of thin elastic double-faced woolen cloth

A double-faced and elastic technology, which is applied in the direction of fabric surface trimming, weaving, and multi-strand fabrics, can solve the problems of thick fabrics and lack of elasticity, and achieve the effect of low preparation cost, low water shrinkage, and fine fabric surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiments 1-9 provide a method for preparing a thin elastic double-sided fabric, which will be described below by taking Embodiment 1 as an example.

[0039] Example 1

[0040] A preparation method of thin elastic double-sided woolen cloth specifically comprises the following preparation steps:

[0041] S1. Worsted yarn: use fine Australian wool with a fineness of 15μm to make 60 / 2 wool yarn as warp yarn; choose fine-count full mercerized wool and elastic yarn with a fineness of 15μm, and twist two strands of spun yarn to make 65 / 2 yarn The yarn is used as a weft yarn, and the elastic yarn is a spandex core-spun yarn made of fine-count full-mercerized wool with a fineness of 15 μm as the outer covering yarn and spandex with a fineness of 8 μm as the core yarn, and the covering ratio is 30 %;

[0042] S2, weaving: the warp yarns and weft yarns obtained from S1 are made of 2 / 2 double-layer weaving to obtain grey fabrics;

[0043] S3. Post-finishing: The grey fabric o...

Embodiment 2、3

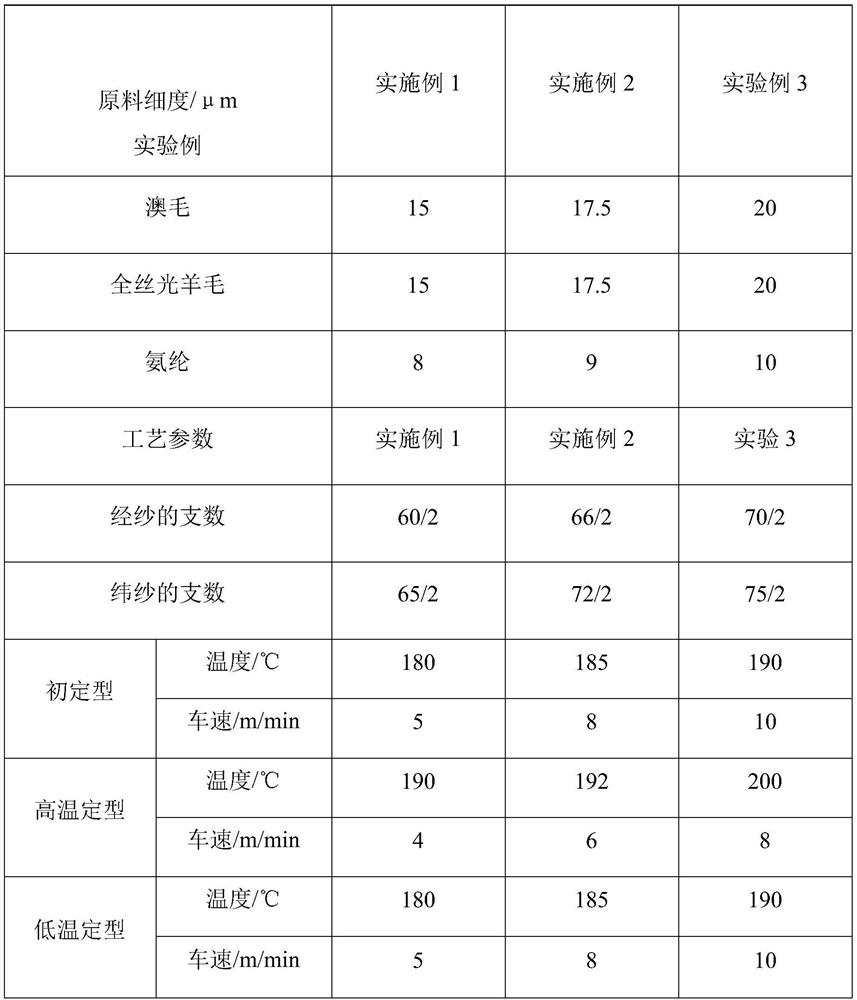

[0044] Embodiments 2 and 3 are the same as Embodiment 1, except that the fineness of the raw materials is different, and the process parameters in the preparation process are different, as shown in Table 1 for details.

[0045] Table 1:

[0046]

Embodiment 4

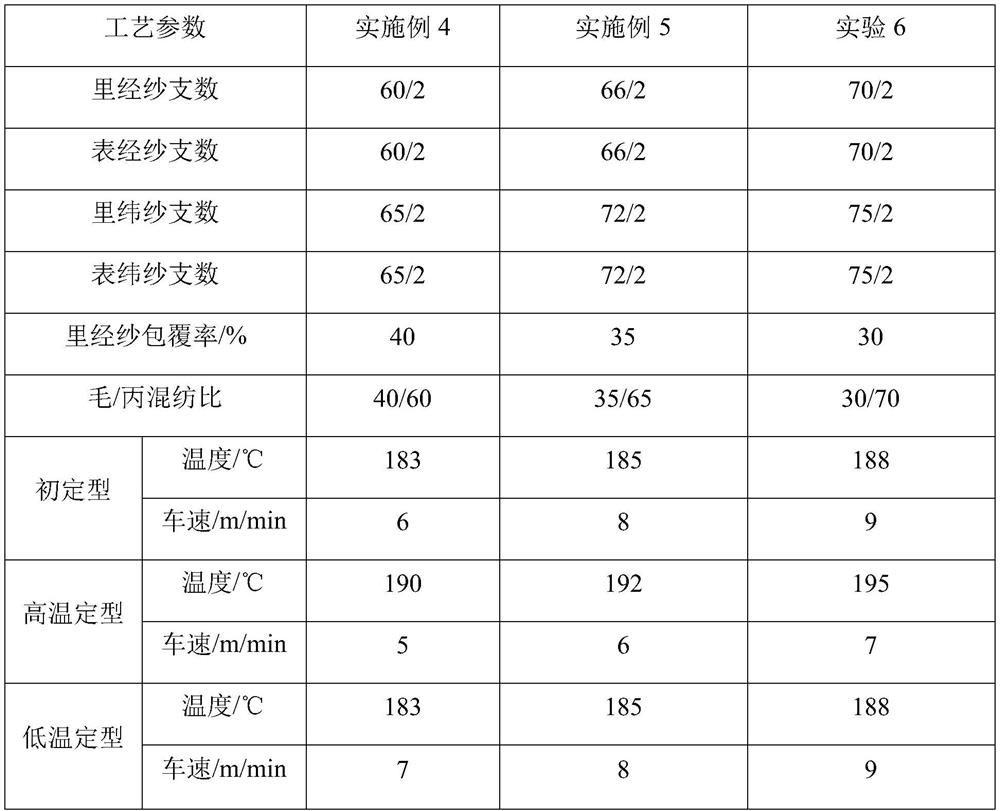

[0048] A preparation method of thin elastic double-sided woolen cloth specifically comprises the following preparation steps:

[0049] S1. Worsted yarn: take Australian wool with a fineness of 17.5 μm as the outer covering yarn, and coffee carbon fiber with a fineness of 10.5 μm as the core yarn, and cover according to the covering rate of 40% to obtain 60 / 2 coffee charcoal Fiber / Australian wool core spun yarn as inner warp;

[0050] The wool / propylene blended yarn of 60 / 2 was obtained by blending Australian wool with a fineness of 17.5 μm and polypropylene filament with a fineness of 10.5 μm according to the blending ratio of 40 / 60 as the surface warp;

[0051] The 65 / 2 yarn is obtained by mixing and twisting fine-count full-mercerized wool with a fineness of 17.5μm and elastic yarn as the inner weft and surface weft yarn. The elastic yarn is made of fine-count full-mercerized wool with a fineness of 17.5μm. Covering yarn, spandex with a fineness of 9 μm is a spandex core-sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com