Method for predicting change trend of impact toughness of Cr13 super stainless steel in lossless and in-situ detection manner

A technology of impact toughness and change trend, applied in the field of electrochemical testing of stainless steel, can solve problems limited to microscopic qualitative or semi-quantitative

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

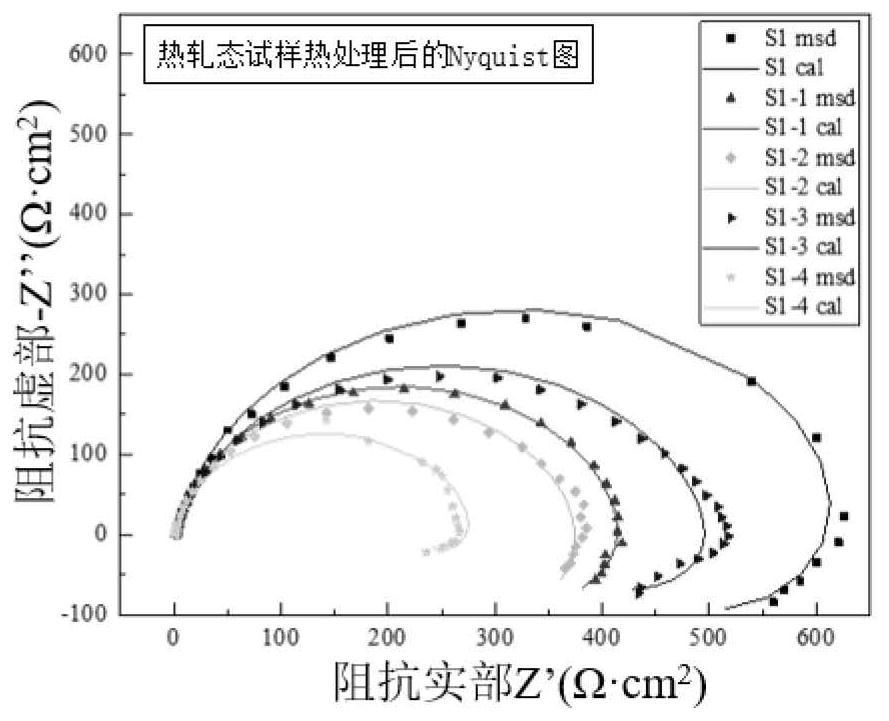

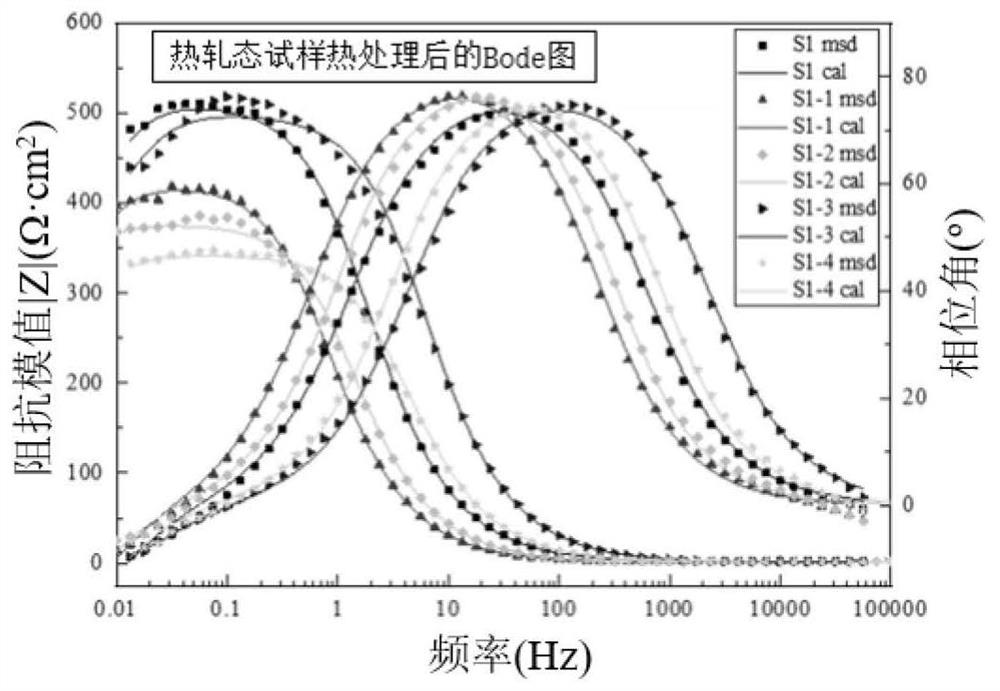

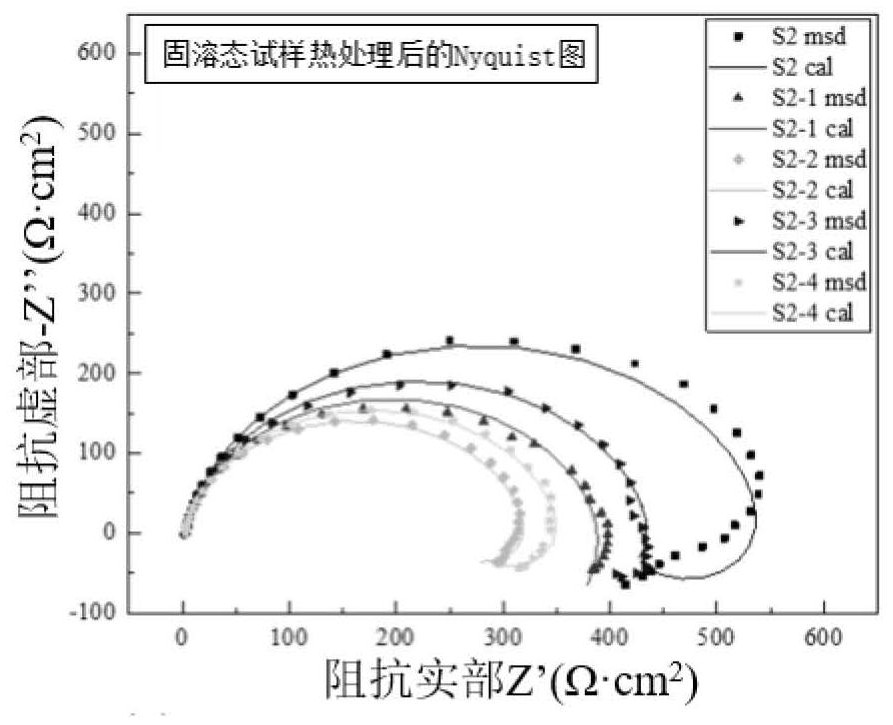

[0022] The technical solutions of the present invention will be further described below through specific embodiments.

[0023] The instrument used for the electrochemical impedance analysis test was a Princeton VersaSTAT 3 electrochemical workstation.

[0024] A non-destructive and in-situ detection method for predicting the change trend of impact toughness of Cr13 super stainless steel is carried out according to the following steps:

[0025] Step 1: Connect the back of the test surface of the sample to be tested with wires and then encapsulate it in epoxy resin and expose only the test surface of the sample to be tested to ensure the area of the test surface of the sample to be tested and the exposure of the sample to be tested. equal area;

[0026] Step 2, the test surface of the sample to be tested obtained in step 1 is ground to 2000 mesh from coarse to fine with SiC sandpaper and mechanically polished, washed with deionized water and absolute ethanol and dried to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com