Mura defect detection method for edge blurring in LCD (Liquid Crystal Display) screen

A technology for edge blurring and defect detection, applied in image analysis, image enhancement, instruments, etc., can solve problems such as edge blurring, achieve the effects of reducing missed detection rate, improving accuracy, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] like Figure 4 As shown, a method for detecting Mura defects with blurred edges in an LCD screen includes the following steps:

[0059] S1: Extract the region of interest in the image by image cropping;

[0060] S2: Perform Gaussian filtering on the image in step S1 to filter out Gaussian noise;

[0061] S3: down-sampling the image after step S2 to reduce the resolution of the image;

[0062] S4: perform edge filling on the image after step S3, and fill the non-screen area of the edge area;

[0063] S5: Select a certain position in the image after step S4 to add noise;

[0064] S6: Differentiate the noise-added image after step S5 and the image obtained in step S4, and enhance the result image after the difference;

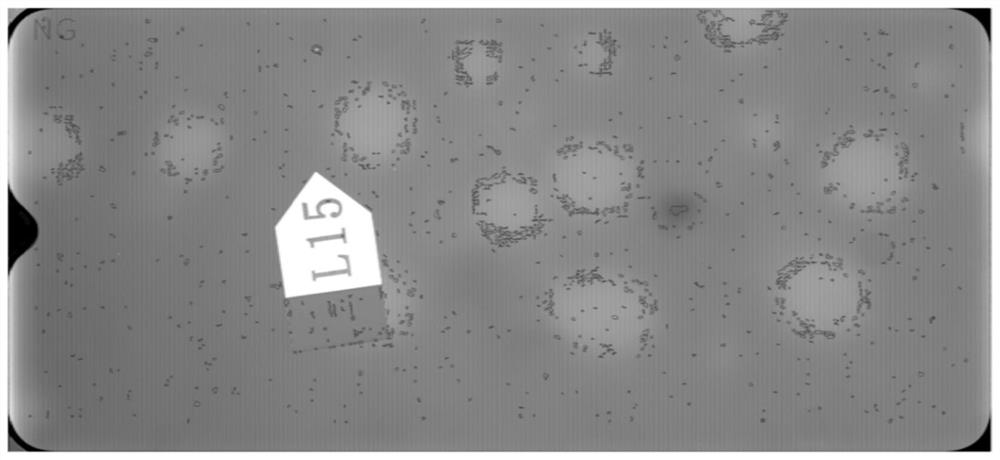

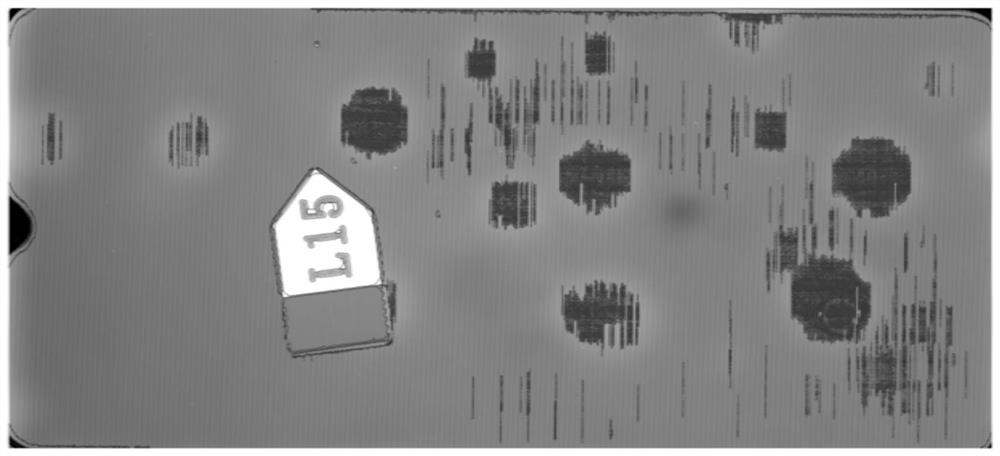

[0065] S7: Perform binarization and expansion processing on the image obtained in step S6 to screen out defects;

[0066] S8: Upsampling and masking the image obtained in step S7 to restore the resolution of the image and shield the false detection o...

Embodiment 2

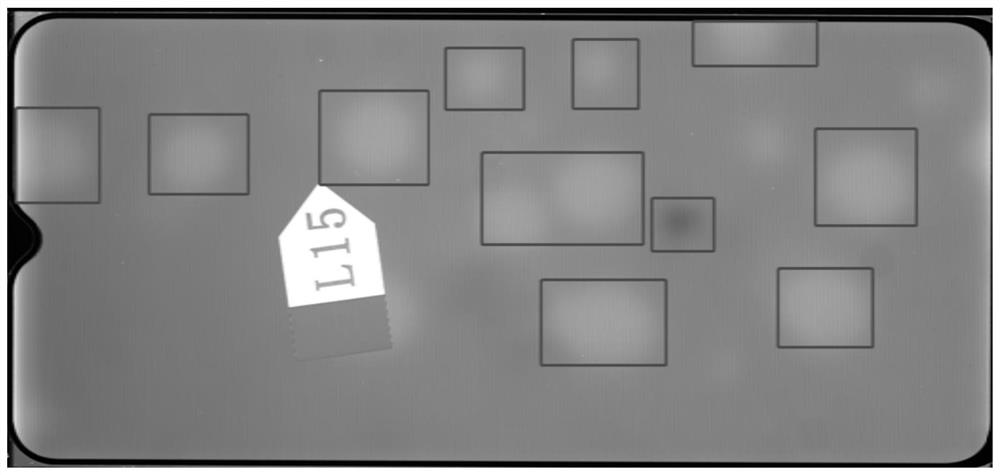

[0086] like Figure 4 As shown, a Mura defect detection method with blurred edges in an LCD screen is divided into eight steps to realize the detection process. The first step is image cropping, which is used to extract the region of interest in the image. The second step of Gaussian filtering is to filter out Gaussian noise. The third step is downsampling, reducing the resolution of the image. The fourth step is edge padding, which fills the non-screen area of the edge area. The fifth step is to add the right amount of noise in the right place. The sixth step is to perform a difference between the image without noise and the image with added noise, and enhance the resulting image after the difference. The seventh step is to perform binarization and dilation processing to screen out defects. The eighth step is to perform upsampling and masking to restore the resolution of the image and shield the false detection of non-screen areas. Through the processing of the above ...

Embodiment 3

[0115] After starting the detection, it is necessary to place the product to be detected in the center of the camera's field of view, then turn on the power to light up the screen, adjust the gray value of the pixels on the screen to a certain threshold (for example, 128), and then use the camera to capture images. The collected images are transferred to the computer, and the collected images are as follows: Figure 5 shown. Figure 5 The black area on the periphery of the middle screen is the bleeding point, which does not belong to the range that needs to be detected. The screen area can be cropped out by manually inputting the screen edge coordinates or automatically calculating the screen edge coordinates. The cropped rendering is as follows Figure 8 shown. According to the cropped screen renderings, the edge information of the screen can be obtained, so as to create a Figure 9 The picture of the mask stencil shown is for use in subsequent mask steps.

[0116] Since ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com