Shrimp meat improver and method for improving quality of shrimp meat

A technology of improving agent and shrimp, which is applied in the field of shrimp improving agent and improving the texture of shrimp, which can solve the problems affecting the flavor, taste and sensory quality of shrimp, and achieve the effect of maintaining umami taste and elastic taste, simple process steps and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

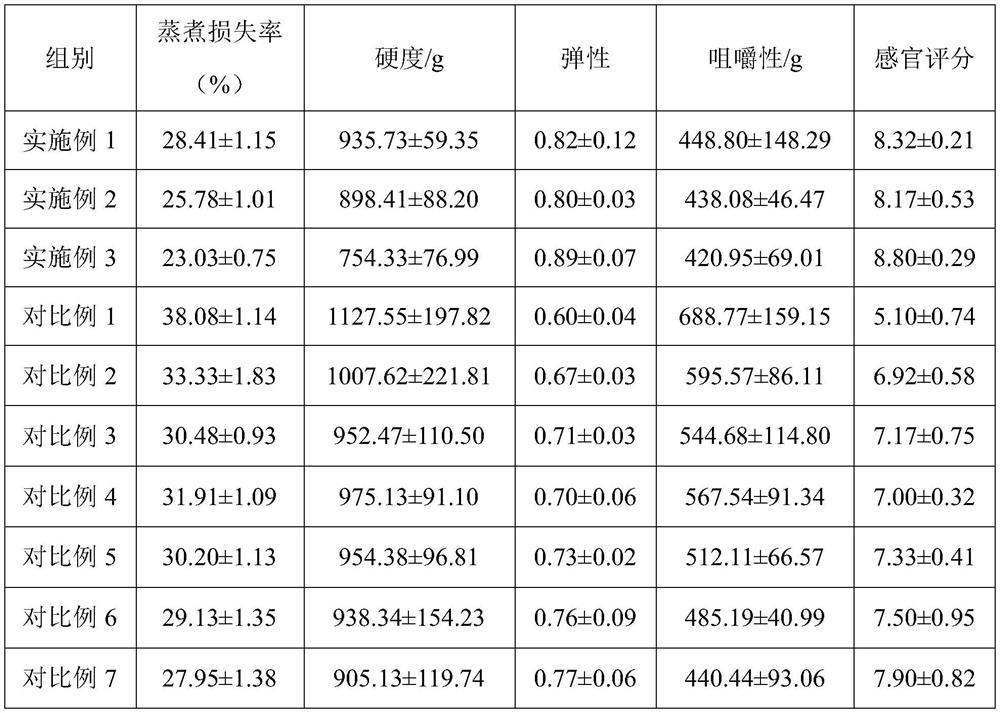

Embodiment 1

[0021] A shrimp improver is composed of the following components by mass percentage: 0.2% sodium citrate, 0.5% sodium bicarbonate, 0.4% trehalose, and the balance is water.

[0022] The specific preparation steps are as follows: after weighing each component according to the above mass percentage, mixing and stirring uniformly.

[0023] The frozen crayfish shrimp was placed in the modifier at a mass-volume ratio of 1:4, soaked for 30 minutes at a temperature of 4 °C, and the shrimp was stirred once every 10 minutes during the soaking. After soaking, take out the shrimp and drain, and control the moisture for further processing according to production requirements.

Embodiment 2

[0025] A shrimp improver is composed of the following components by mass percentage: 0.5% sodium citrate, 0.7% sodium bicarbonate, 0.5% trehalose, and the balance is water.

[0026] The specific preparation steps are as follows: after weighing each component according to the above mass percentage, mixing and stirring uniformly.

[0027] The frozen crayfish shrimp was placed in the modifier at a mass-to-volume ratio of 1:4, soaked for 30 minutes at a temperature of 4 °C, and the shrimp was stirred once every 10 minutes during the soaking. After soaking, take out the shrimp and drain, and control the moisture for further processing according to production requirements.

Embodiment 3

[0029] A shrimp improver is composed of the following components by mass percentage: 0.8% sodium citrate, 0.6% sodium bicarbonate, 0.3% trehalose, and the balance is water.

[0030] The specific preparation steps are as follows: after weighing each component according to the above mass percentage, mixing and stirring uniformly.

[0031] The frozen crayfish shrimp was placed in the modifier at a mass-to-volume ratio of 1:4, soaked for 30 minutes at a temperature of 4 °C, and the shrimp was stirred once every 10 minutes during the soaking. After soaking, take out the shrimp and drain, and control the moisture for further processing according to production requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com