Polishing and polishing device for mobile phone cover plate machining

A technology for mobile phone covers and grinding discs, which is applied to grinding drive devices, machine tools suitable for grinding workpiece planes, and metal processing equipment. It can solve problems such as low repair efficiency and increased labor costs, and achieve improved efficiency and quality. Improve the polishing quality and achieve uniform polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

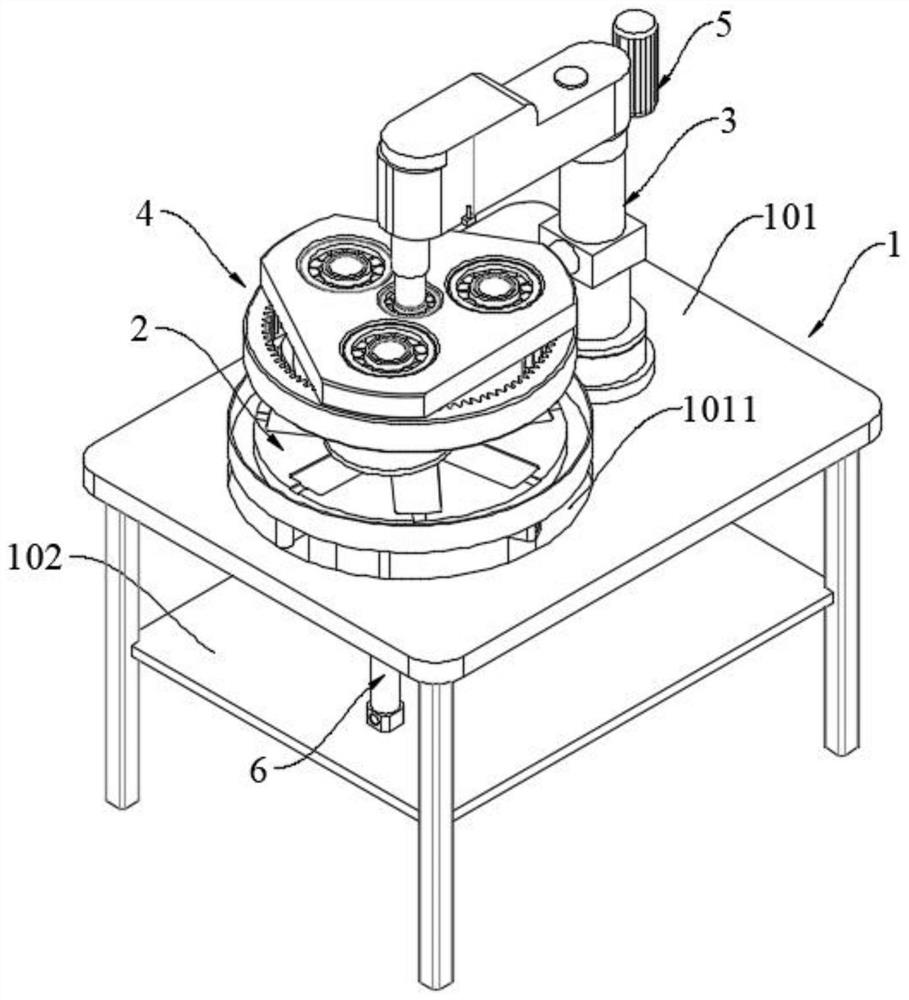

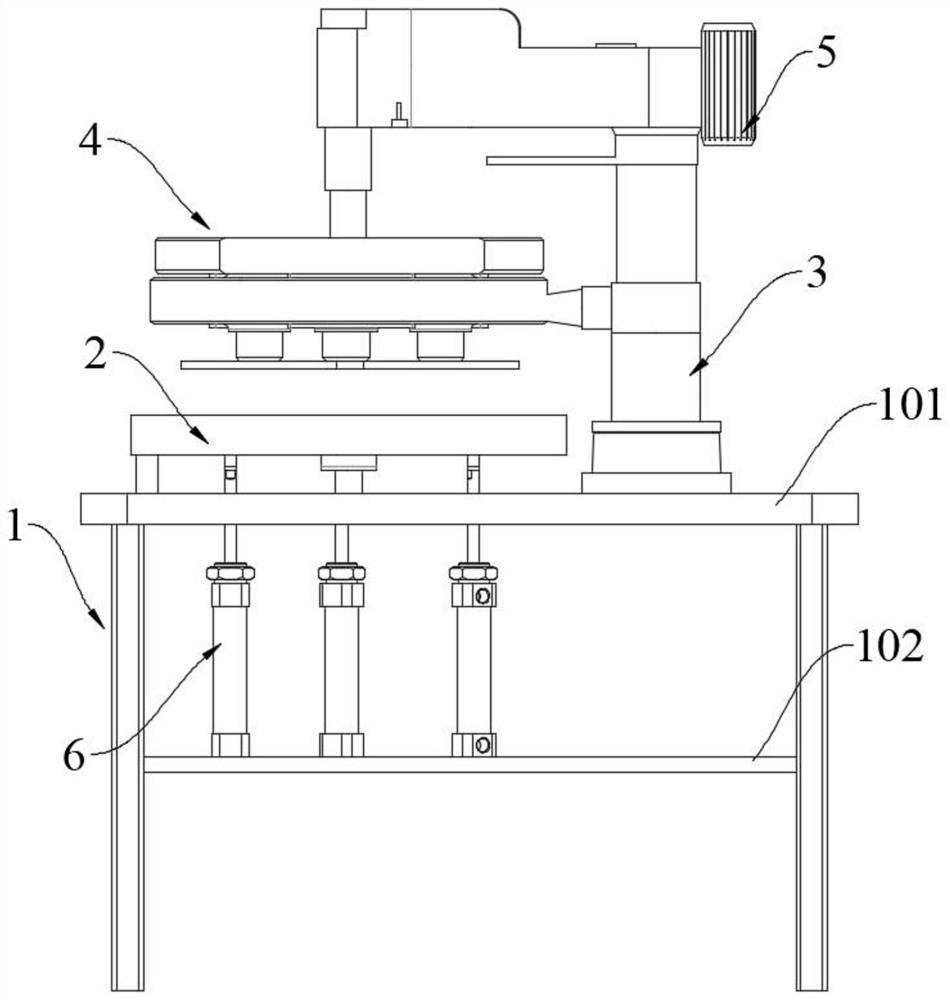

[0037] see Figure 1-Figure 4 As shown, the present invention is a polishing and polishing device for mobile phone cover processing, including an operation table 1, a material tray mechanism and a polishing mechanism, the operation table 1 includes an upper table surface 101 and a lower table surface 102, and the polishing mechanism includes a polishing bracket 3 And the grinding disc assembly 4, the feeding tray mechanism includes the feeding tray 2. The grinding mechanism is fixedly installed on the upper table surface 101 , and the material tray mechanism is fixedly installed on the lower table surface 102 . The upper table 101 is provided with a through hole 1011 which is matched with the material tray 2 , and the lower table 102 is fixedly installed with three cylinders 6 that drive the material tray 2 to rise and fall, and the movable ends of the three cylinders 6 are fixedly connected to the lower surface of the material tray 2 .

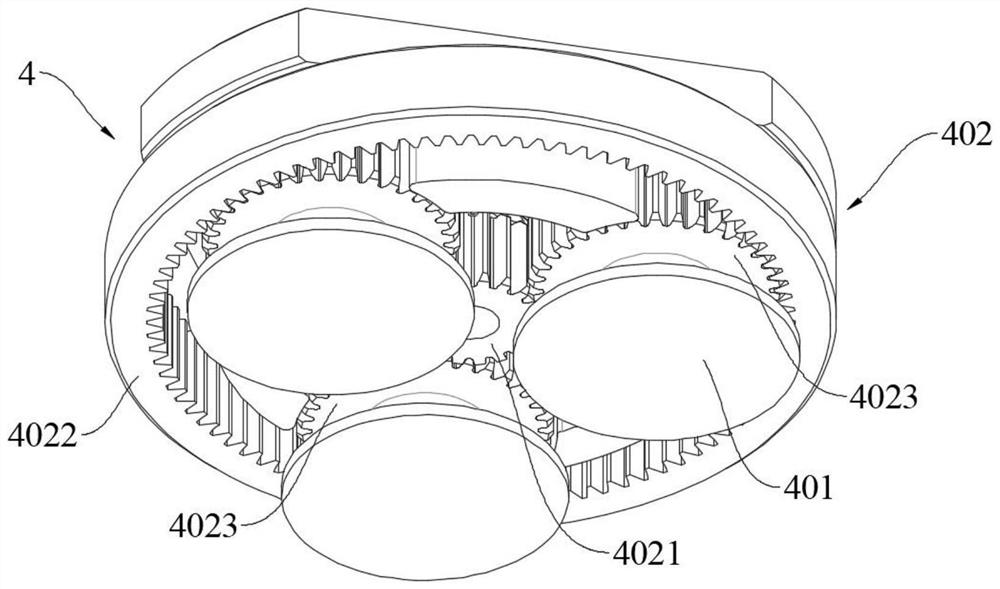

[0038] see Figure 4 As shown, the ...

Embodiment 2

[0043] Based on the first embodiment, the difference between the second embodiment is:

[0044] see Figure 5-Figure 10 As shown, a hole cover 203 is fixedly connected to the top of the liquid injection hole 202 , and the peripheral side surface of the hole cover 203 is threadedly connected to the inner wall of the liquid injection hole 202 . The cover plate 203 has seven notches 2031 evenly formed on the side wall near the top, and the seven notches 2031 are arranged corresponding to the cover plate grooves 201 . The upper surface of the feeding tray 2 is provided with seven water grooves 204 at both ends of the cover plate groove 201 . The slot 2031 makes the polishing liquid flowing out of the liquid injection hole 202 flow to the water tank 204 in the horizontal direction, and the water tank 204 plays a guiding role for the polishing liquid, so that the polishing liquid flows into the cover plate groove 201 more accurately, and the utilization rate of the polishing liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com