Preparation method of high-air-permeability three-layer co-extrusion film

A three-layer co-extrusion and air permeability technology is applied in the field of preparation of highly air-permeable three-layer co-extruded films. Stretching speed, reducing unreliability, small effect of air permeability deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The concept, specific structure and technical effects of the present invention will be clearly and completely described below in conjunction with the embodiments and the accompanying drawings, so as to fully understand the purpose, solutions and effects of the present invention. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

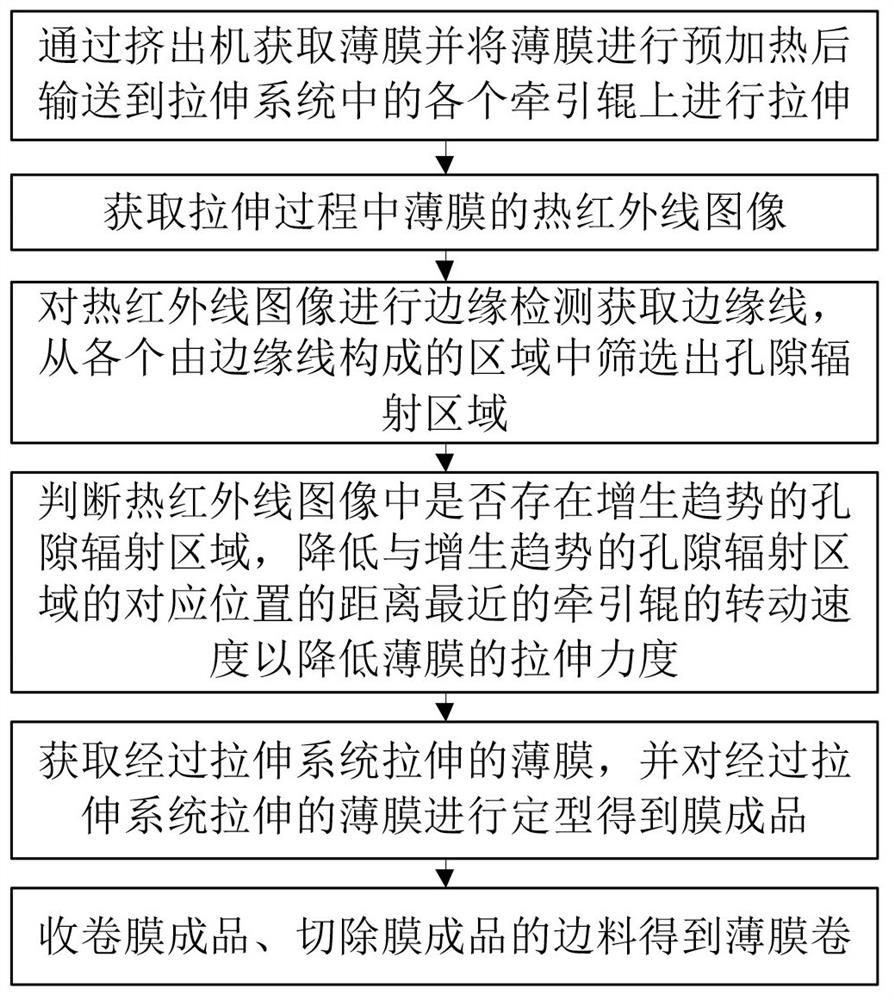

[0059] like figure 1 Shown is a flow chart of a preparation method of a highly air-permeable three-layer co-extruded film, which is combined below figure 1 To illustrate a preparation method of a highly breathable three-layer co-extruded film according to an embodiment of the present invention, the method includes the following steps:

[0060] S1. Obtain the film through an extruder and preheat the film and transport it to each traction roller in the stretching system for stretching;

[0061] S2. Obtain a thermal infrared ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap