Rapid battery replacing device for industrial vehicle and matched battery assembly

An industrial vehicle and battery assembly technology, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve problems such as use disadvantages, achieve the effects of increasing the use range, prolonging battery life, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the various embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and structural, method or functional changes made by those skilled in the art according to these embodiments are all included in the protection scope of the present invention.

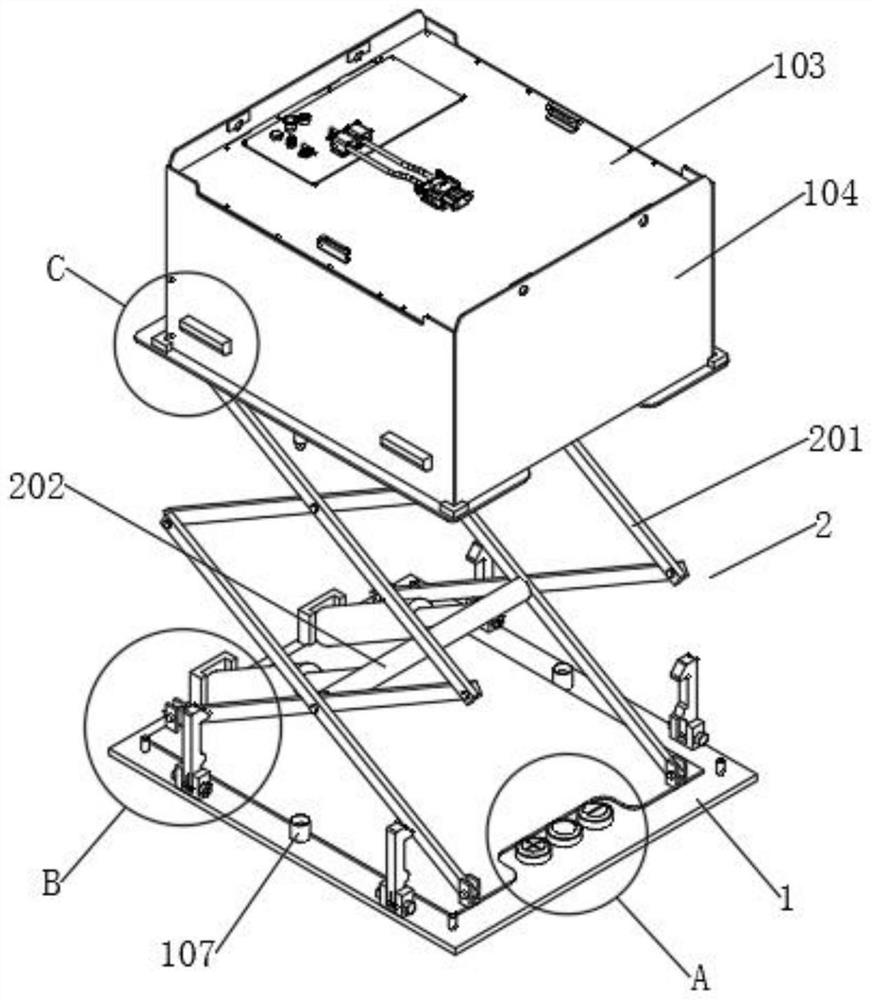

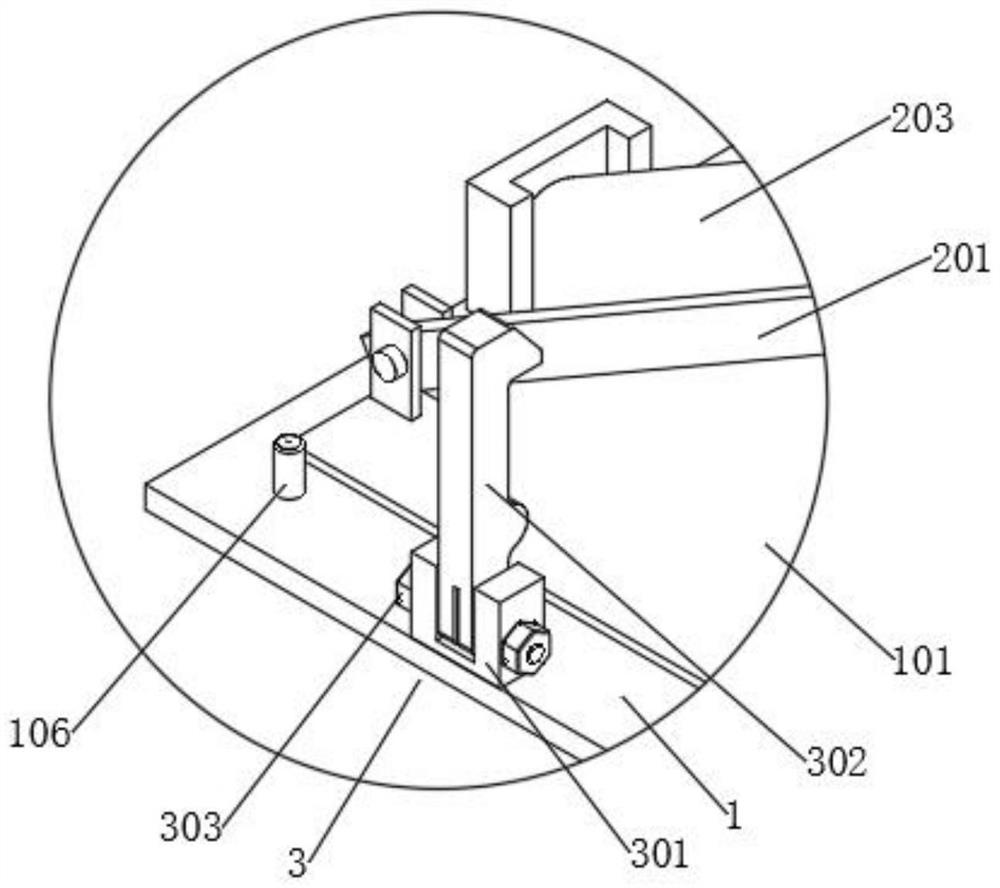

[0040] The invention discloses a quick power exchange device and a matching battery assembly for an industrial vehicle, refer to Figure 1-Figure 9 As shown, it includes a base 1 , a lifting mechanism 2 and a plurality of fastening devices 3 .

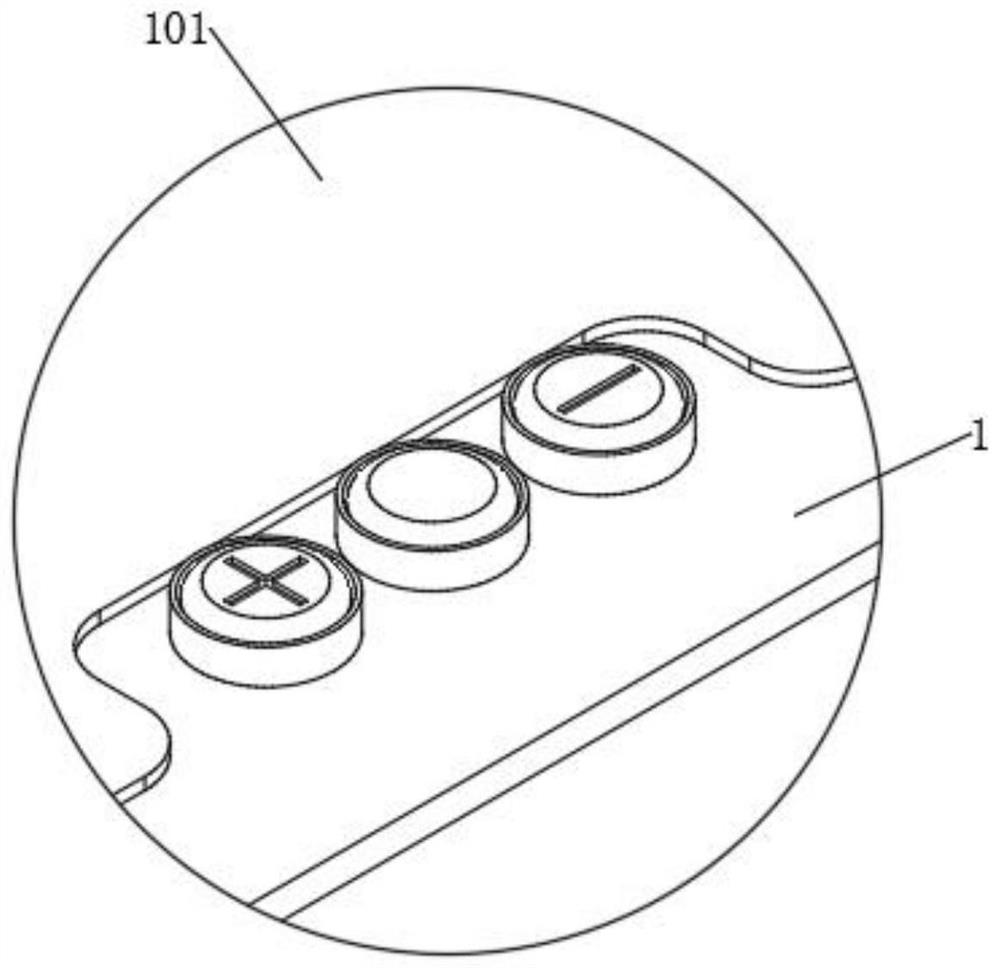

[0041] Wherein, a control board 101 is connected to the base 1 for being electrically connected with the carrying platform 102, and then can supply power to the industrial vehicle.

[0042] In addition, the control board 101 is electrically connected with the discharge seat end, and the specific position of the discharge seat end can be referred to figure 1 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com