Premixed flow state filling material of easily-weathered rock aggregate

A technology of filling material and weathered rock, which is applied in the field of building materials, can solve the problems of uneven settlement in the backfill area of the foundation trench, threaten the safety of people's lives and property, and affect the appearance of the city. Sexual and inclusive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

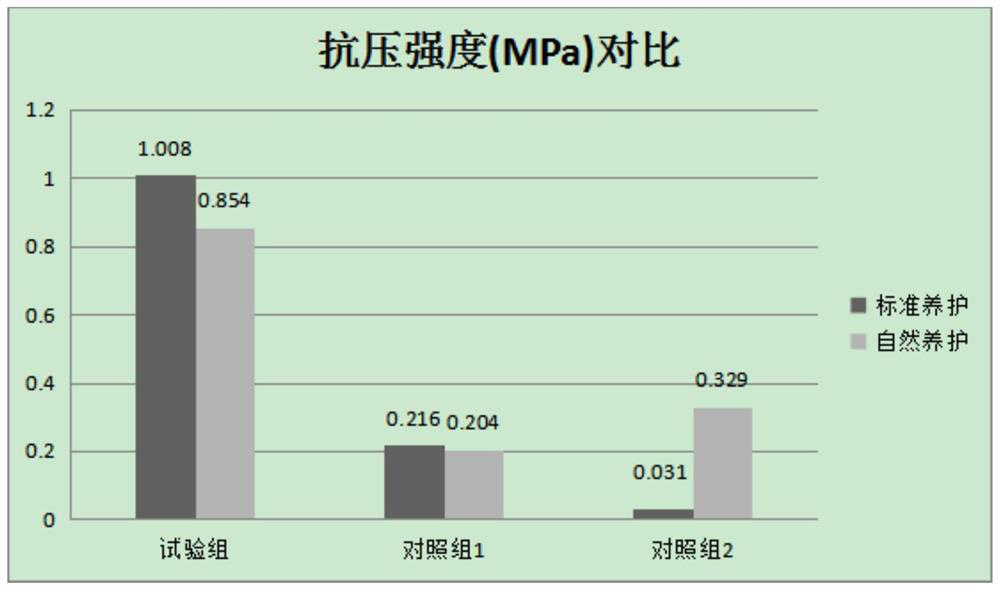

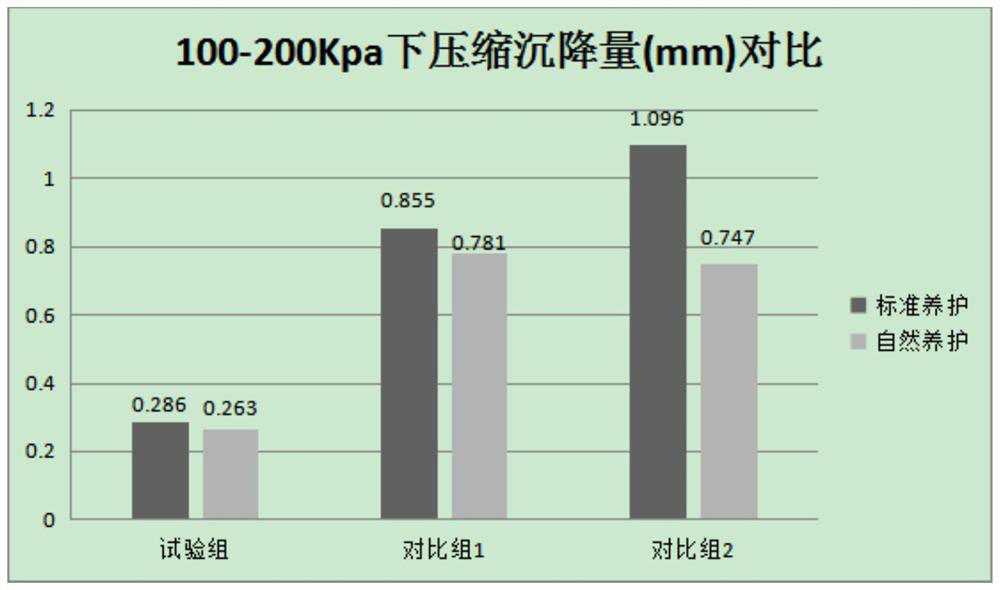

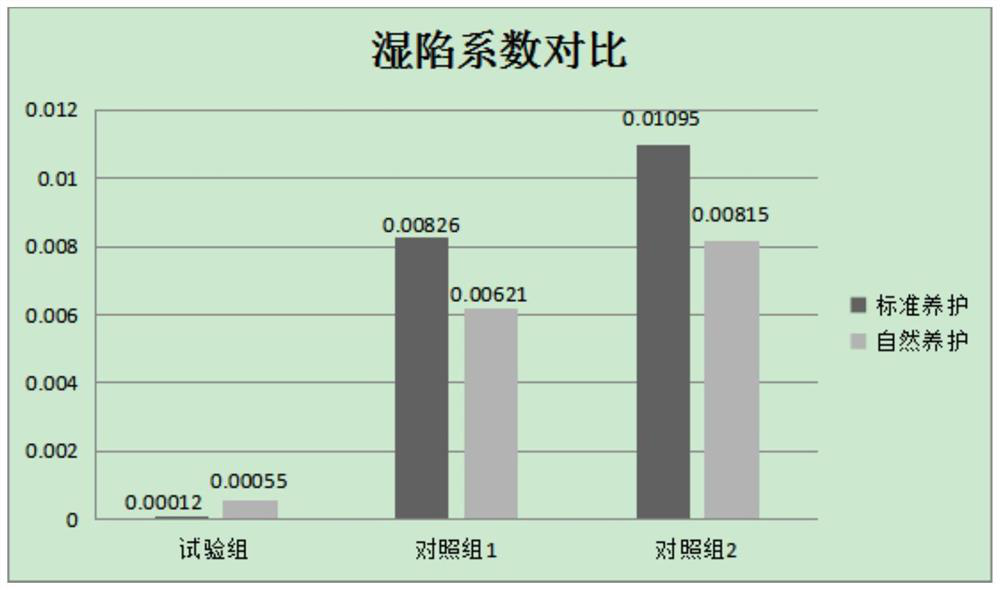

Embodiment 1

[0062] Limestone, shale, sandstone, schist, phyllite and other easily weathered rocks excavated from the foundation trench, bentonite and collapsible loess are the main materials, and the curing agent is the secondary material, and the curing agent is ordinary silicate Cement, the cement strength grade is 42.5MPa, and the admixture is a retarded solid pumping agent. The aggregate is transported into the mixer, and at the same time, the curing agent, admixture and a certain proportion of water are mixed to form a slurry, which is also transported to the mixer. After the mixer is evenly stirred, a filling material with good fluidity and a certain strength after hardening is formed . The composition materials of the ready-mixed fluid filling material of easily weathered rock, bentonite and collapsible loess aggregate in this example 1 are: the fine aggregate is bentonite, collapsible loess and easily weathered rock fine aggregate respectively account for the aggregate 5%, 36% an...

Embodiment 2

[0064] Limestone, shale, sandstone, schist, phyllite and other easily weathered rocks excavated from the foundation trench, bentonite and collapsible loess are the main materials, and the curing agent and admixture are the secondary materials, and the curing agent is ordinary Portland cement, the cement strength grade is 42.5MPa, and the admixture is a retarded solid pumping agent. The aggregate is transported into the mixer, and at the same time, the curing agent, admixture and a certain proportion of water are mixed to form a slurry, which is also transported to the mixer. After the mixer is evenly stirred, a filling material with good fluidity and a certain strength after hardening is formed . The composition material of the ready-mixed fluid filling material of easily weathered rock aggregate in this example 2 is: the fine aggregate is bentonite, collapsible loess and easily weathered rock fine aggregate respectively account for 11% and 22% of the total aggregate amount. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com