Multi-subdivision composite cylindrical foundation and construction method thereof

A cylindrical foundation and construction method technology, applied in the direction of basic structure engineering, construction, etc., can solve problems such as insufficient bearing capacity, and achieve the effects of improving bearing capacity, expanding the scope of application, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

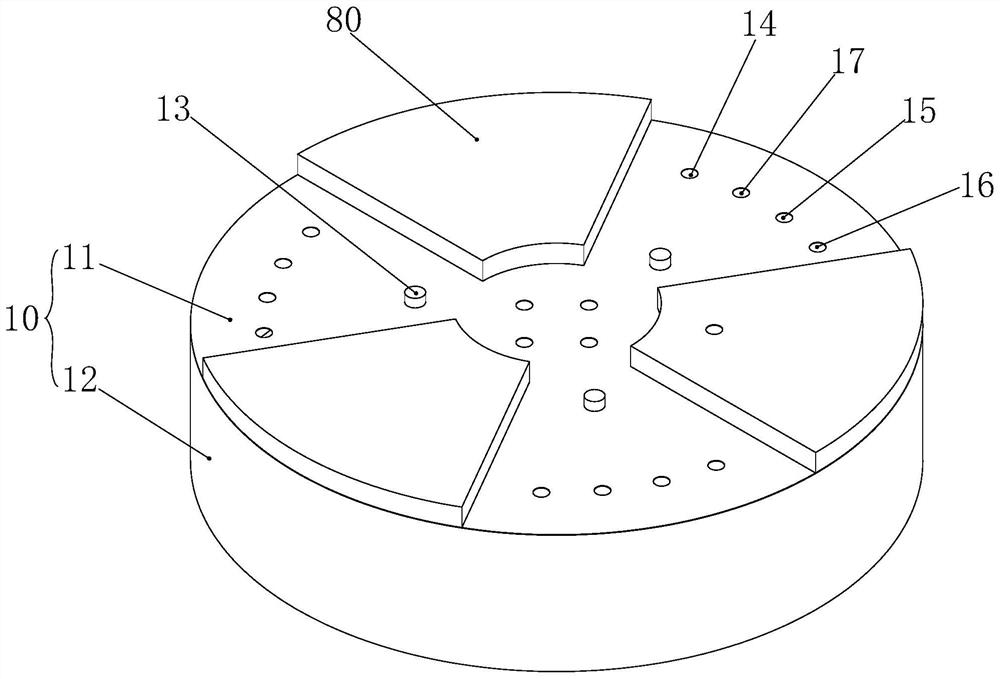

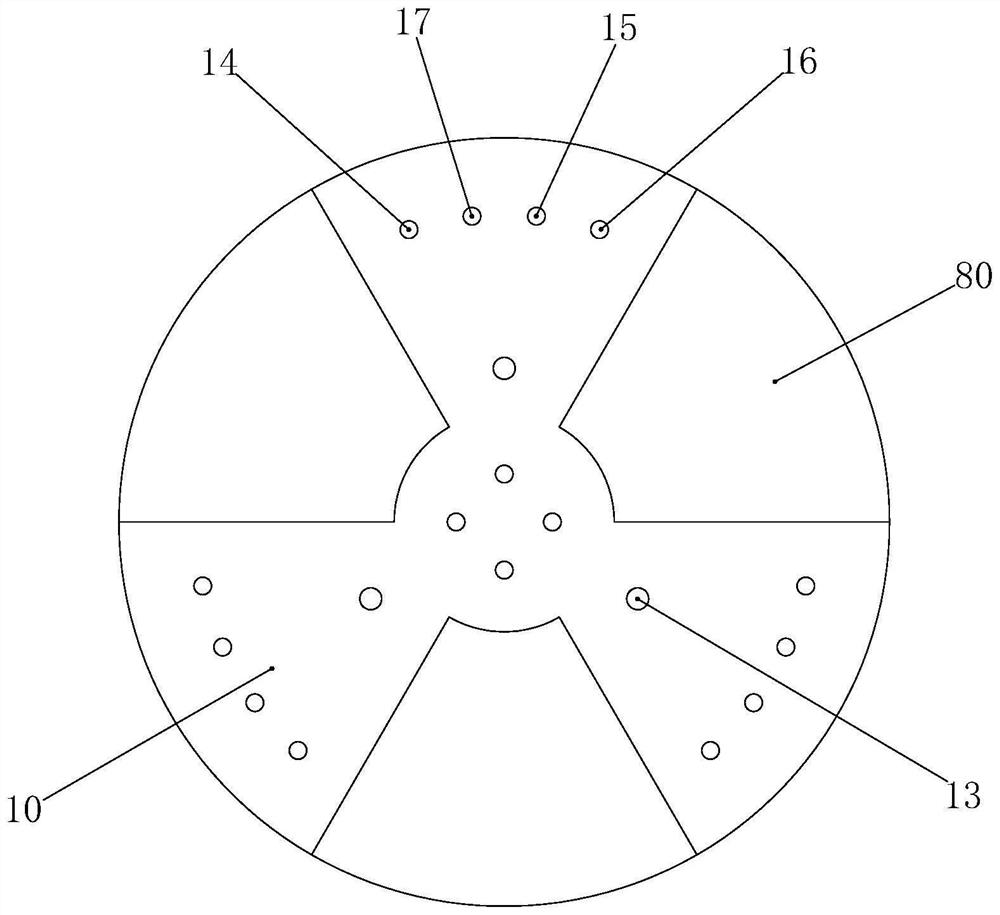

[0069] Embodiment: the construction method of the above-mentioned multi-division composite cylindrical foundation, such as Image 6 , Figure 7 As shown, the construction method includes the following steps:

[0070] S10: Prefabricating a multi-division composite cylindrical foundation and ballast plate 80 on land.

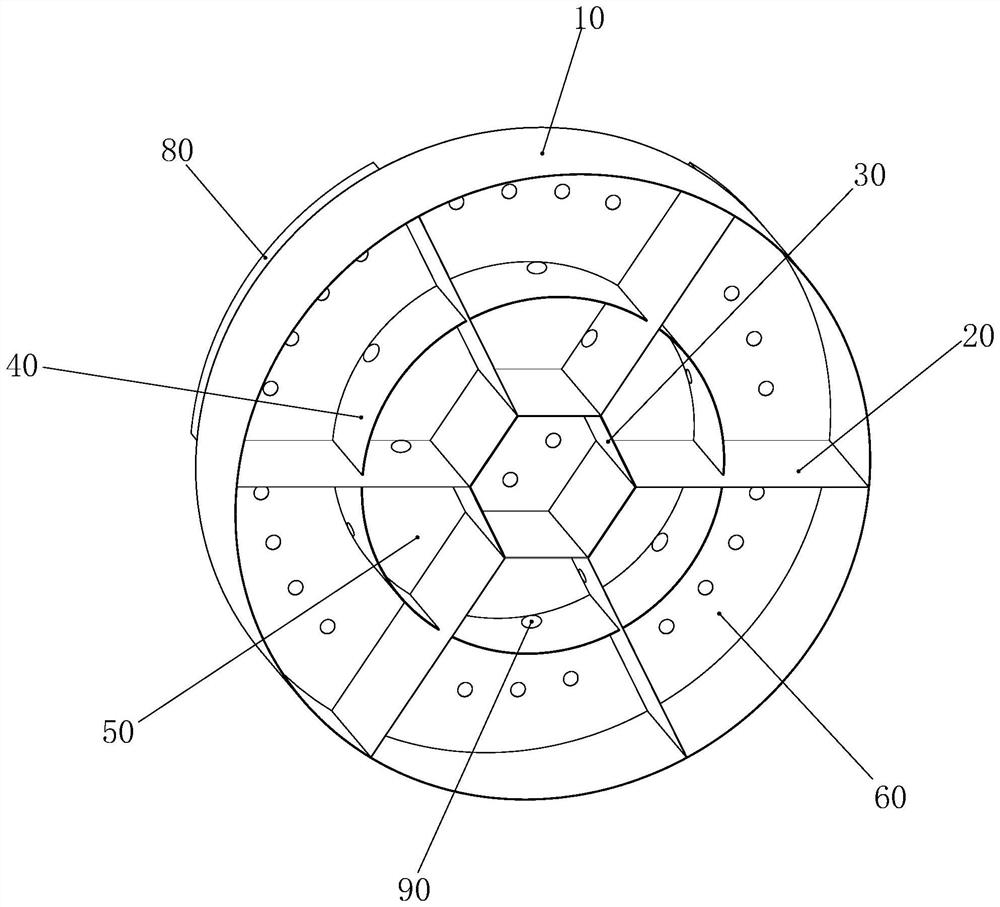

[0071] S20: After assembling and debugging the multi-division composite cylindrical foundation and the superstructure, tower and fan, hoist it into the water, and check the middle subdivision 70, inner ring subdivision 50 and outer ring subdivision 60 of the multi-division composite cylindrical foundation air tightness.

[0072] S30 : Adjust the water-air ratio of the middle sub-chamber 70 , the inner ring sub-chamber 50 and the outer ring sub-chamber 60 to be the middle sub-chamber 70 , the outer ring sub-chamber 60 , and the inner ring sub-chamber 50 .

[0073] Specifically: as Image 6 As shown (the dotted line in the figure is the liquid level position), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com