Underground composite heater for in-situ development of underground mineral products

A heater, in-situ technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve problems such as narrow application range, inability to apply to formations, and inability to meet the requirements of different types of unconventional oil and gas resource extraction, etc. achieve the effect of guaranteeing normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make those skilled in the art better understand the technical solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described The embodiments are only some of the embodiments of the present invention, but not all of the embodiments.

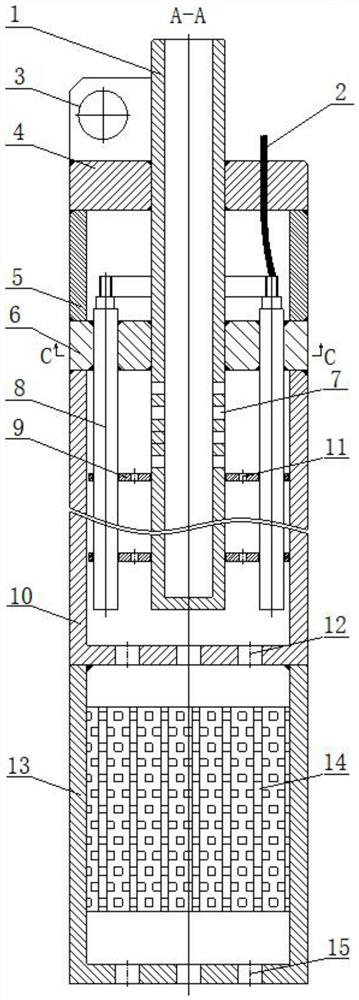

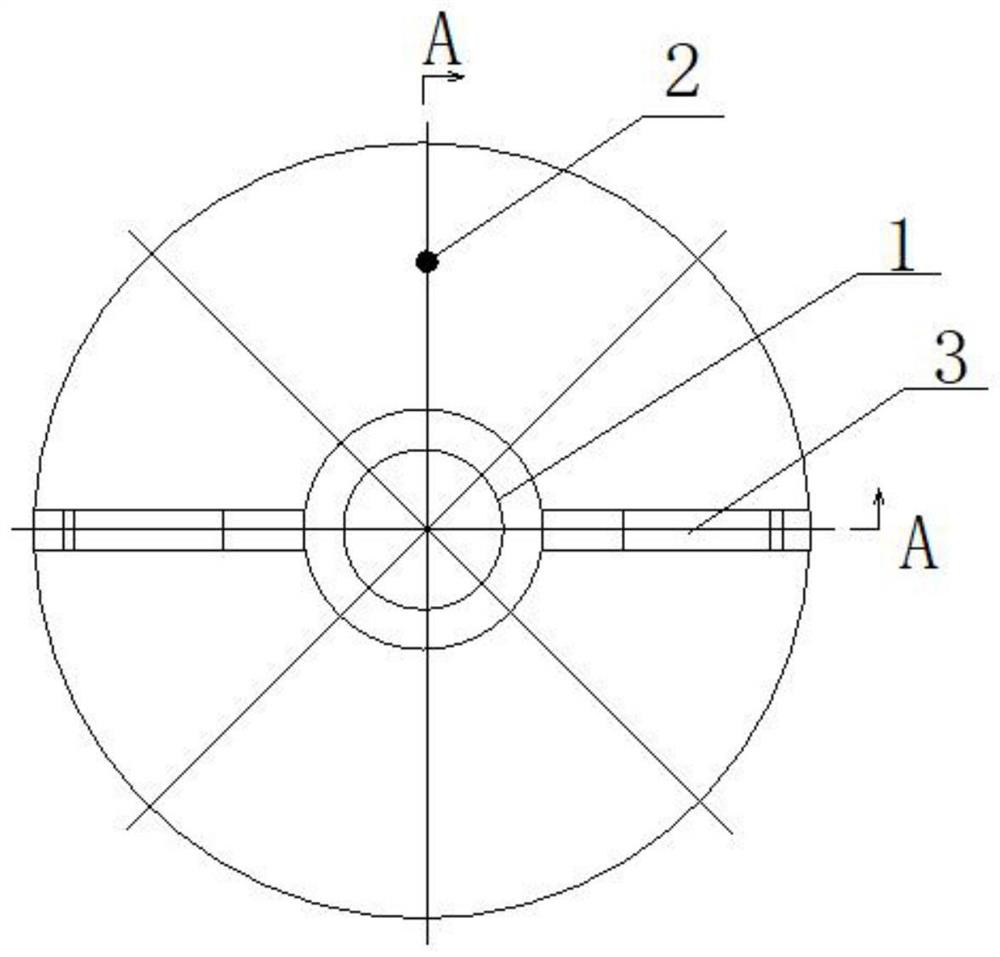

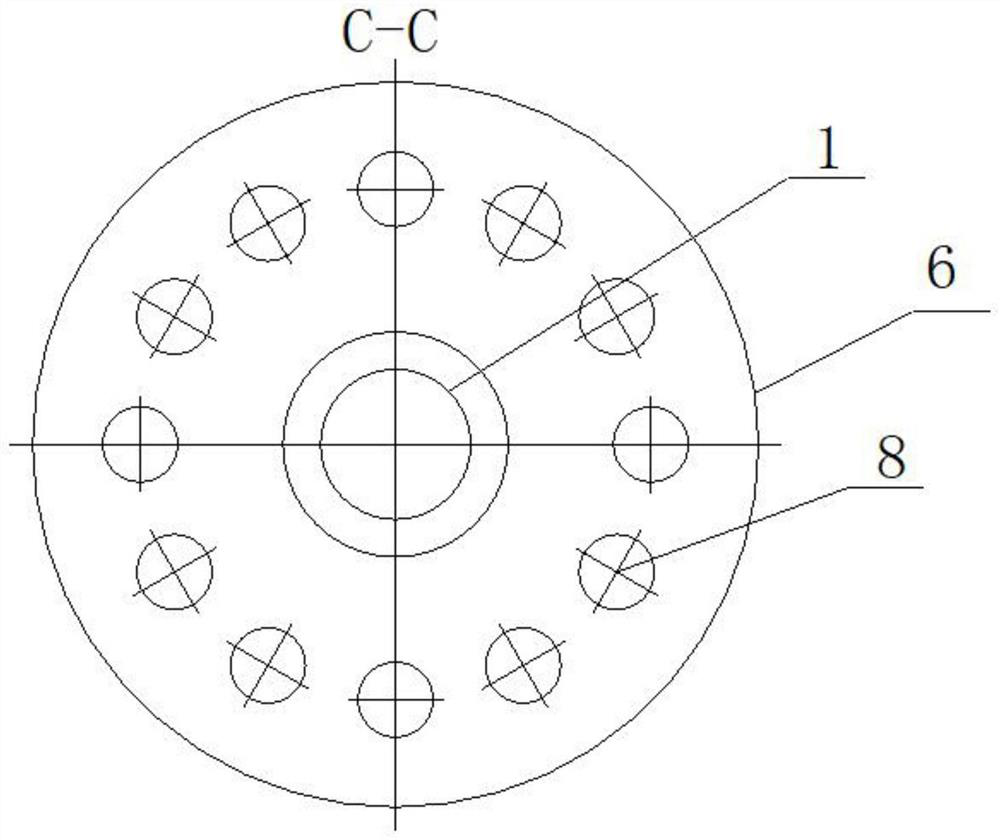

[0020] figure 1 A schematic diagram of the structure of a downhole composite heater used for in-situ development of underground minerals is shown; figure 2 A top view of a downhole composite heater for in-situ development of underground minerals is shown, i.e. figure 1 The A-A rotated cross-sectional view; image 3 The cross-sectional view of the lower cover plate of the cable compartment in the downhole composite heater used for the in-situ development of underground minerals is shown, that is, figure 1 C-C sectional view of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com