Waste grease collecting box, collecting system, grease replacing system and waste grease collecting box cleaning method

A collection system and collection box technology, applied in the field of waste grease collection box, can solve the problems of increased abrasive particles, laboriousness, space occupation, etc., and achieve the effects of high space utilization, time saving, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

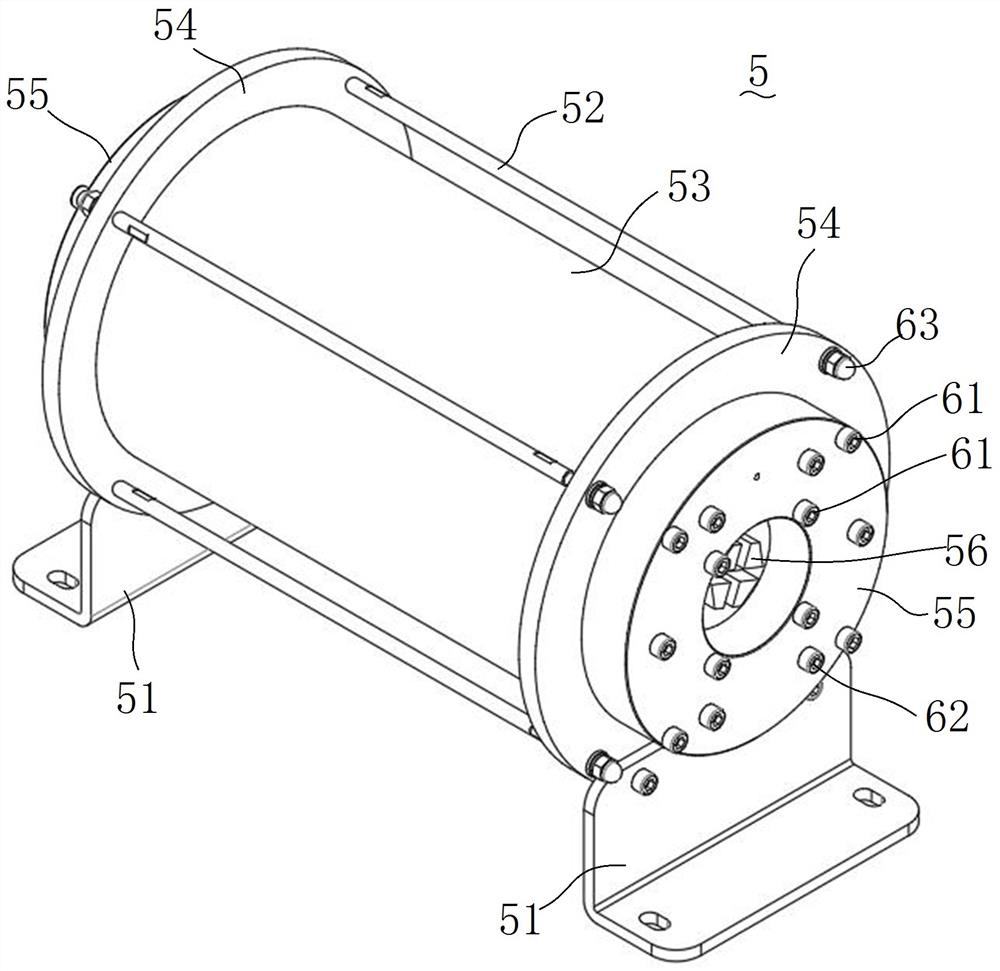

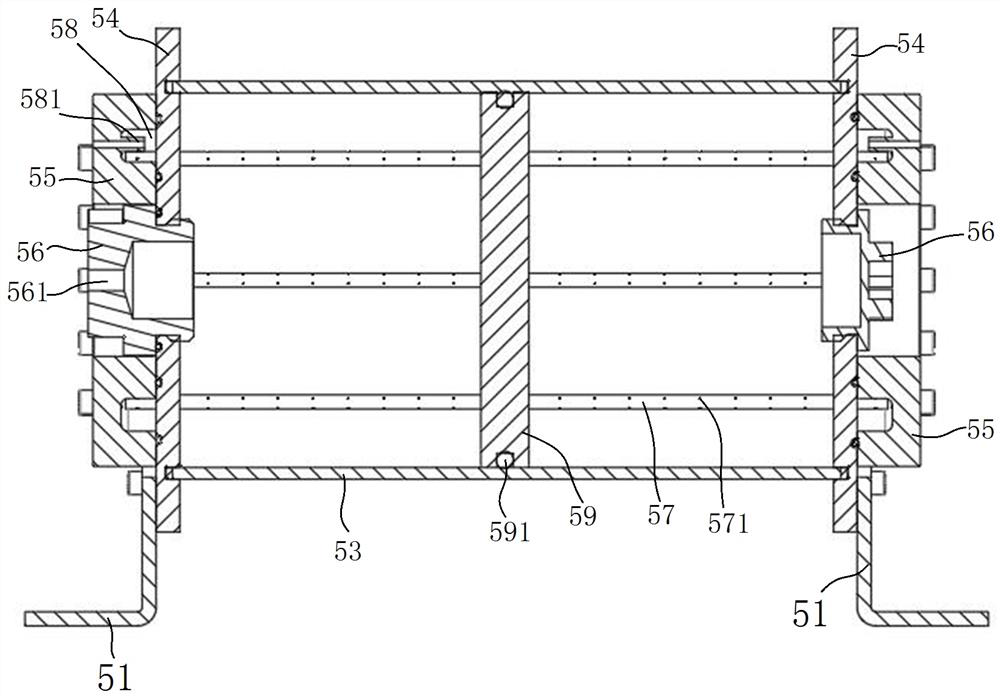

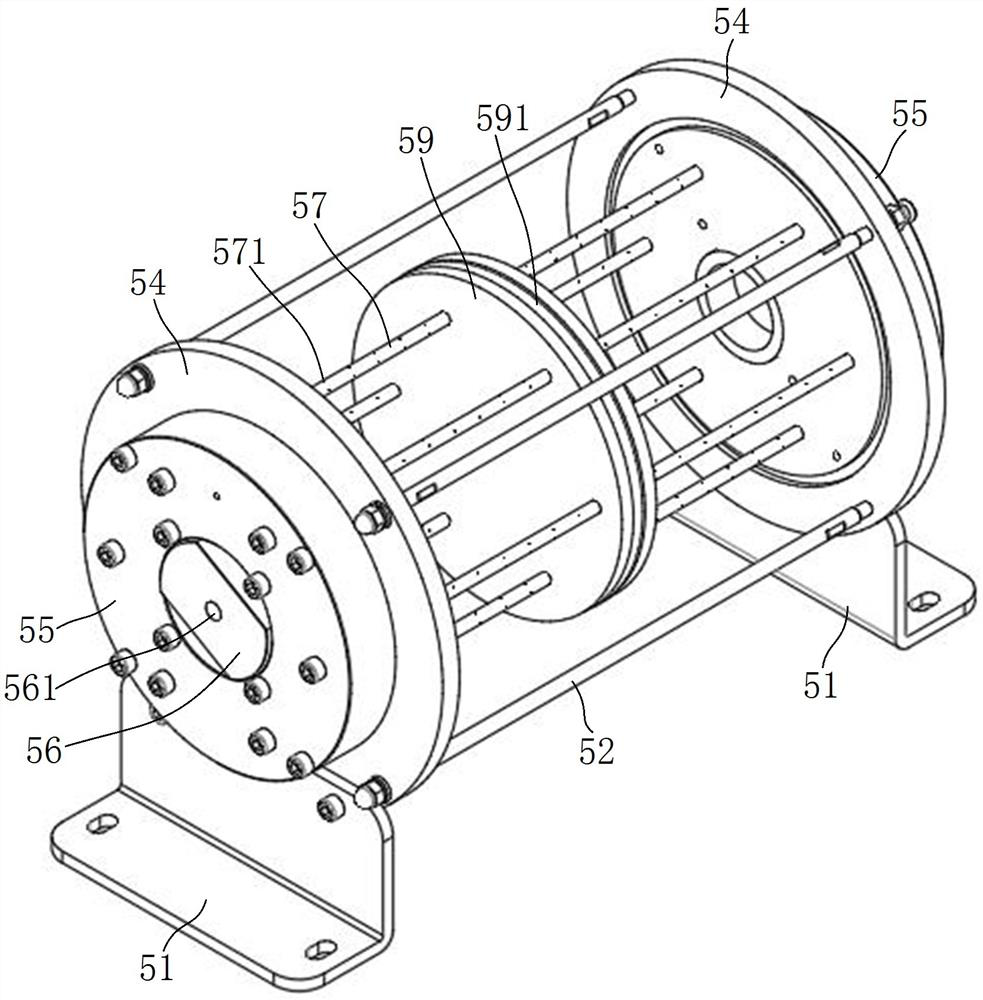

[0081] An embodiment of the waste fat collection system of the present invention: as Figure 7 The schematic diagram of the waste grease collection system is shown. Taking the fan pitch bearing as an example, the main components of the waste grease collection system are the grease suction and discharger 3 and the drive device. Figure 7 In order to control the dual oil circuits to drive a plurality of grease suction and discharge devices 3 to work, the grease suction and discharge devices 3 are installed at each grease discharge hole of the pitch bearing, that is, a plurality of grease suction and discharge devices 3 are arranged around each pitch bearing. In other embodiments Among them, an electric fat suction and discharge device 3 can also be used, and each fat suction and discharge device 3 of the electric fat suction and discharge device 3 has an independent motor as the power, and the volume is small. The waste grease collection box 5 is detachably installed on the hub,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com