Industrial explosive detonation velocity measurement target line manufacturing device

A technology of industrial explosives and manufacturing devices, which is applied in the direction of ammunition, ammunition testing, and offensive equipment. It can solve the problems of large distance errors between target lines, target lines not installed, and time-consuming and labor-intensive target lines. Accurate installation and detonation velocity measurement, avoiding the effect of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

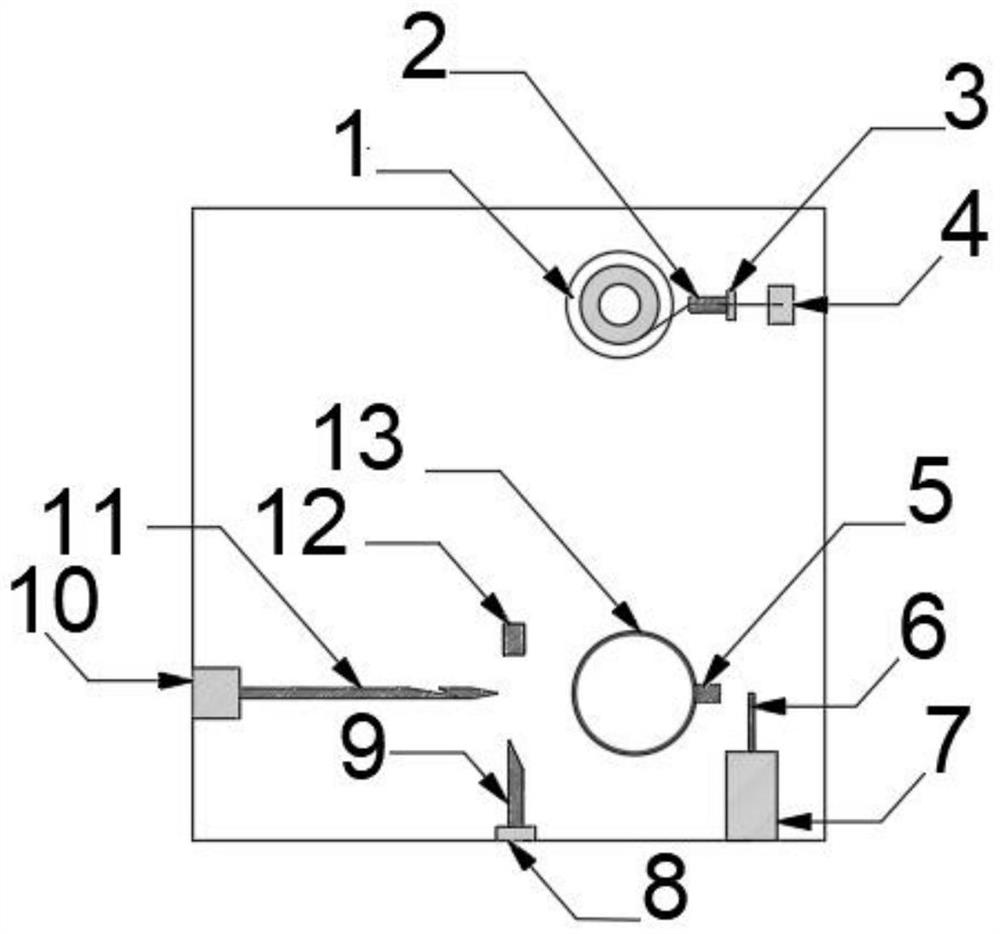

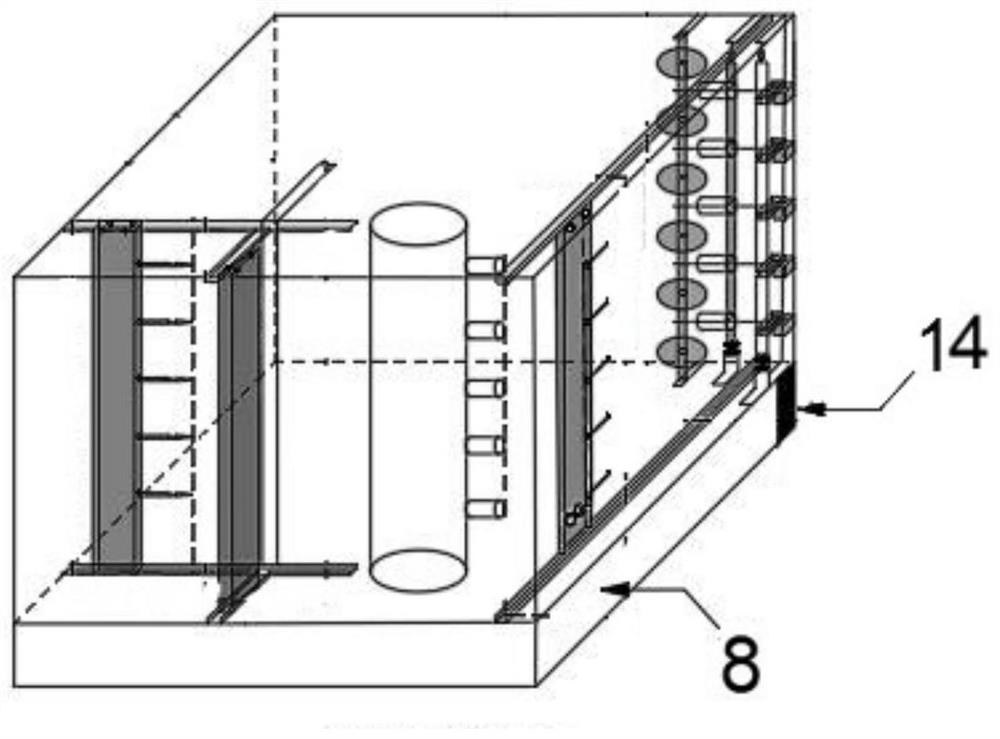

[0030] A device for making a target line for measuring the detonation velocity of an industrial explosive in this embodiment, refer to the attached figure 1 and 2 , including an explosion-proof box body 8, and at least one set of wire-paying mechanisms, at least one set of wire-threading mechanisms and explosive positioning assemblies arranged in the explosion-proof box body 8;

[0031] The explosive positioning assembly is used to fix the coil to be measured;

[0032] The threading mechanism is arranged on one side of the explosive positioning assembly, and the pay-off mechanism is used to take out a segment of the target wire from the enameled wire coil and send it to the other side of the explosive positioning assembly;

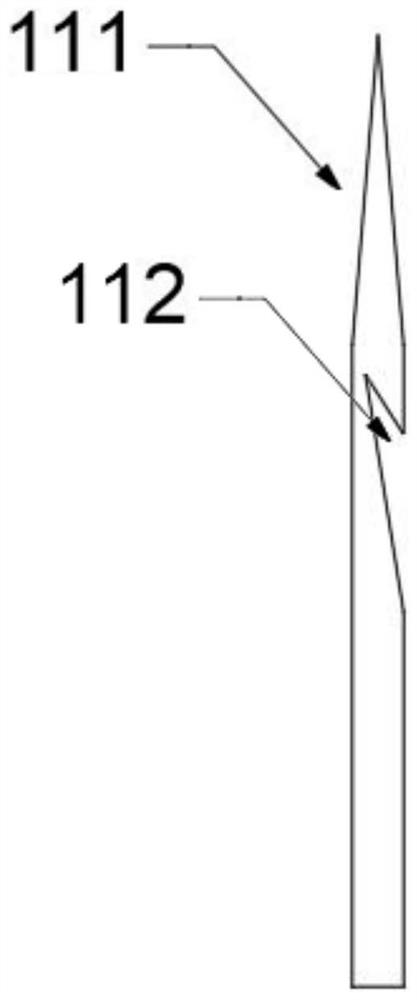

[0033] The threading mechanism includes a threading drive part, a threading movable base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com