Quality analysis and optimization method and system for multi-time scale data fusion

A multi-time scale, data fusion technology, applied in database indexing, data processing applications, structured data retrieval, etc., can solve problems such as quality loss, localized quality analysis control, etc., to reduce product quality loss, ensure accuracy, The effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

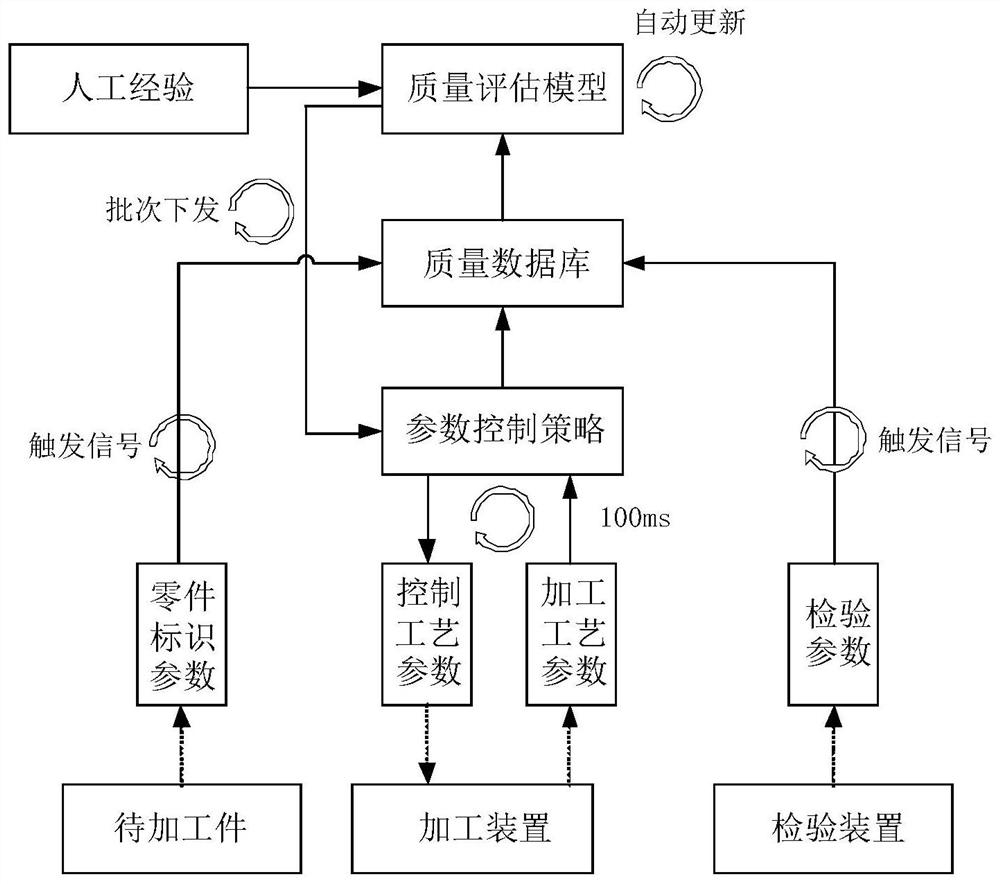

[0041] like figure 1 As shown, this embodiment provides a quality analysis and optimization method for multi-time scale data fusion, as follows:

[0042] S1. To associate product production process data and build a quality database

[0043] The product data is associated with the part number, and the part number includes the material part number and the material batch number; based on the part number, the process parameters and detection parameters are collected and associated with the part number to build a quality database;

[0044] S2. Build a quality assessment model

[0045] Build a quality evaluation model based on human experience and quality database; according to the current processing situation, issue control process parameters to the parameter control strategy for a single piece or batch;

[0046] S3. Online Control

[0047] For the processing equipment, the online control of the processing process is carried out through the parameter control strategy to ensure t...

Embodiment 2

[0051] This embodiment provides a quality analysis and optimization method for multi-time-scale data fusion, which is specifically as follows:

[0052] S1. To associate product production process data and build a quality database

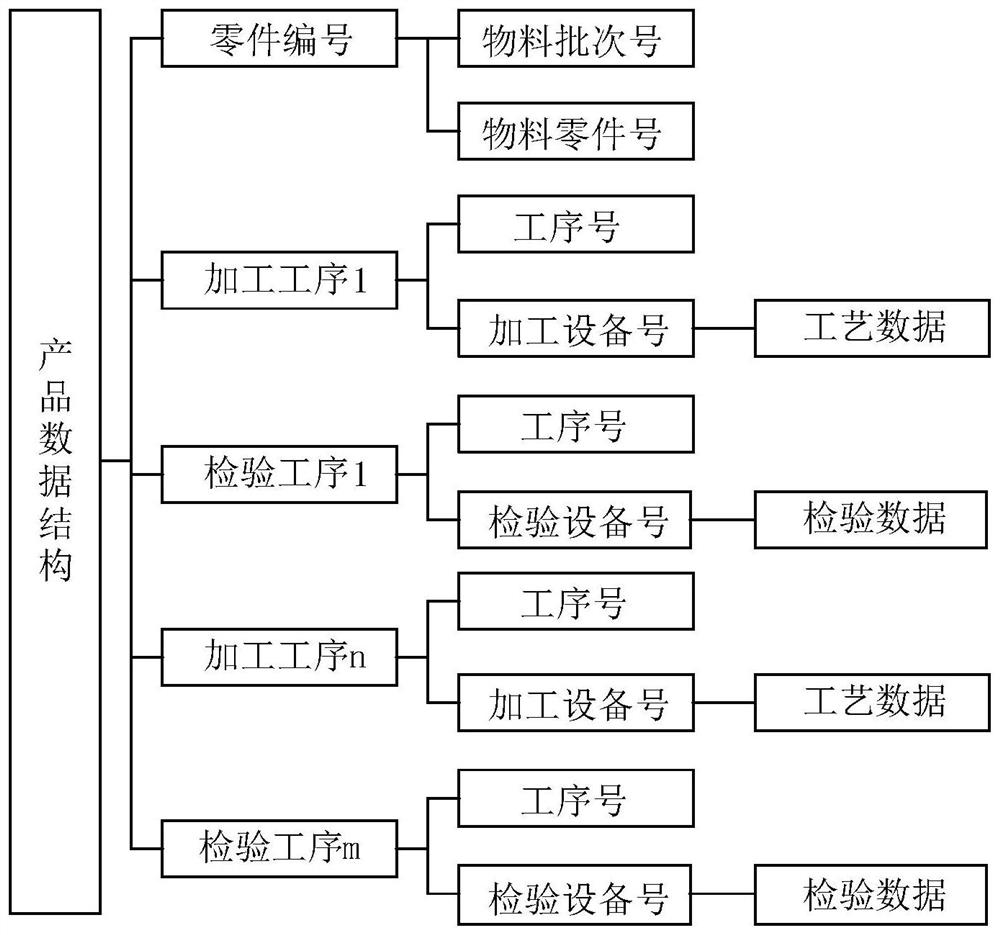

[0053] The product data is associated with the part number, and the part number includes the material part number and the material batch number; based on the part number, process parameters and inspection parameters are collected and associated with the part number to construct a quality database. The process parameters include the processing procedure number, processing equipment number and process data, and the process data is bound to the processing procedure number and processing equipment number; the detection parameters include the detection procedure number, detection equipment and detection data, and the detection data and the detection procedure number , Detect device binding.

[0054] The whole process data association framework is as fol...

Embodiment 3

[0065] This embodiment provides a quality analysis and optimization system for multi-time scale data fusion, including one or more modules for storing in a memory and configured to be executed by one or more processors; one or more modules include:

[0066] A module that associates product production process data and builds a quality database. In the module, product data is associated through part numbers, and the part numbers include material part numbers and material batch numbers; based on the part numbers, process parameters and inspection parameters are collected, and Associated with part numbers, build quality database.

[0067] A module for building a quality assessment model. In the module, a quality assessment model is constructed based on human experience and quality database; according to the current processing conditions, single-piece or batch control process parameters are issued to the parameter control strategy.

[0068] The online control module, for the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com