Trench gate semiconductor device

A trench gate and semiconductor technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as unreliable breakdown voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

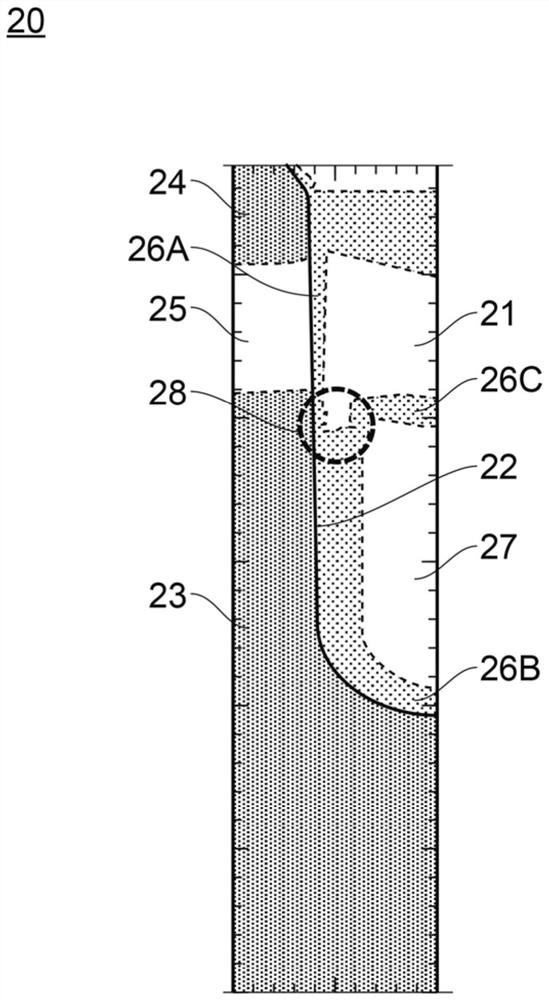

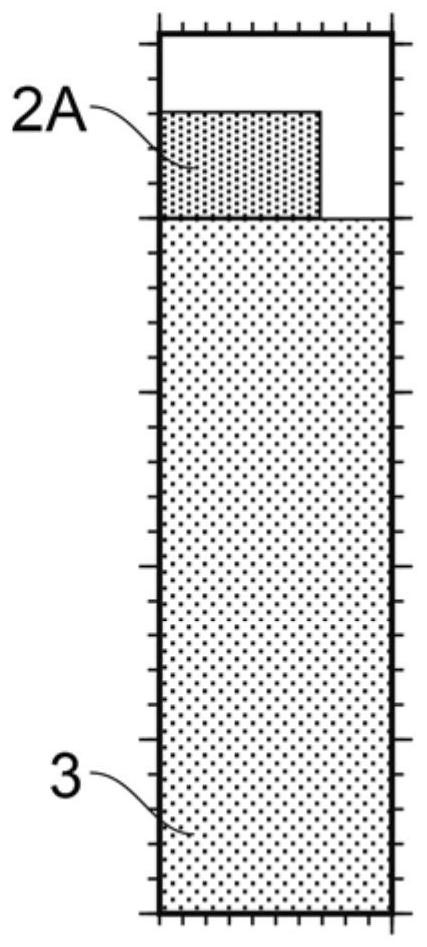

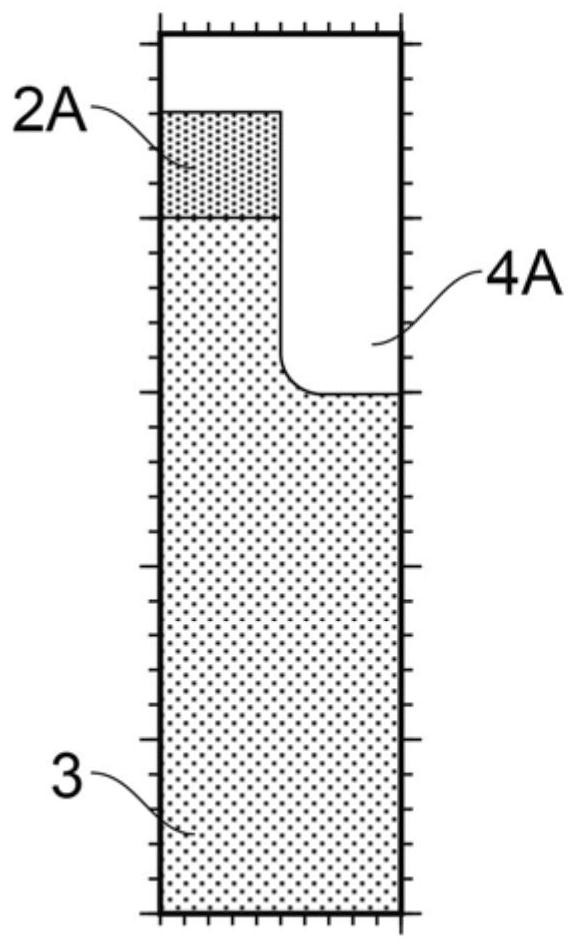

[0044] Reference will be made below to the accompanying drawings. It should be noted that the same reference numbers may be used to refer to the same or similar parts. In addition, Figure 1 and Figures 2A to 2H The unit cells depicted in are symmetrical along the vertical axis in these figures. Therefore, for illustration purposes, only half of the unit cell is shown.

[0045] Figures 2A to 2H A first part of the process for fabricating the unit cell 1 of the trench gate semiconductor device 100 in which a silicon semiconductor region is used is shown. will refer to image 3 The remaining process steps are described. It should be noted that this process can be used to fabricate a single unit cell individually, or to fabricate multiple unit cells simultaneously on the same semiconductor region.

[0046] refer to Figure 2A , a first mask layer 2A is deposited and patterned onto the surface of the semiconductor region. For example, the first mask layer 2A is provided on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com