Predictive current control method of semi-centralized open-winding permanent magnet synchronous motor system

A permanent magnet synchronous motor and current prediction technology, which is applied in the direction of current controller, motor generator control, AC motor control, etc., can solve the problems of raising cost, large volume, unfavorable predictive current control, etc., and achieve the goal of steady-state performance improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Attached below figure 1 Describe the technical solution of the present invention in detail;

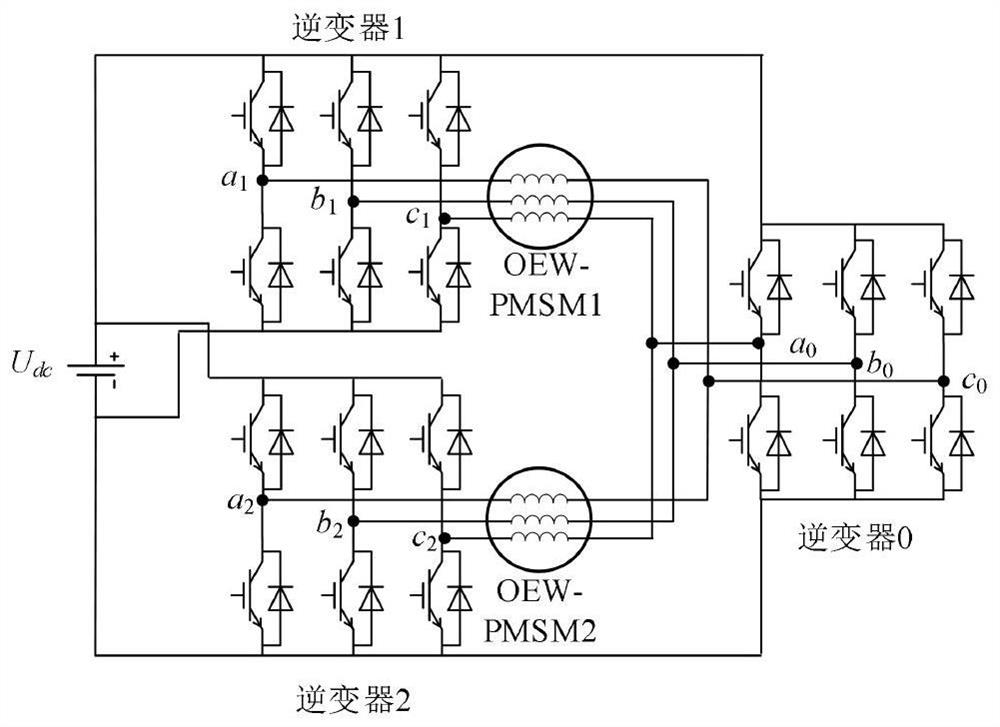

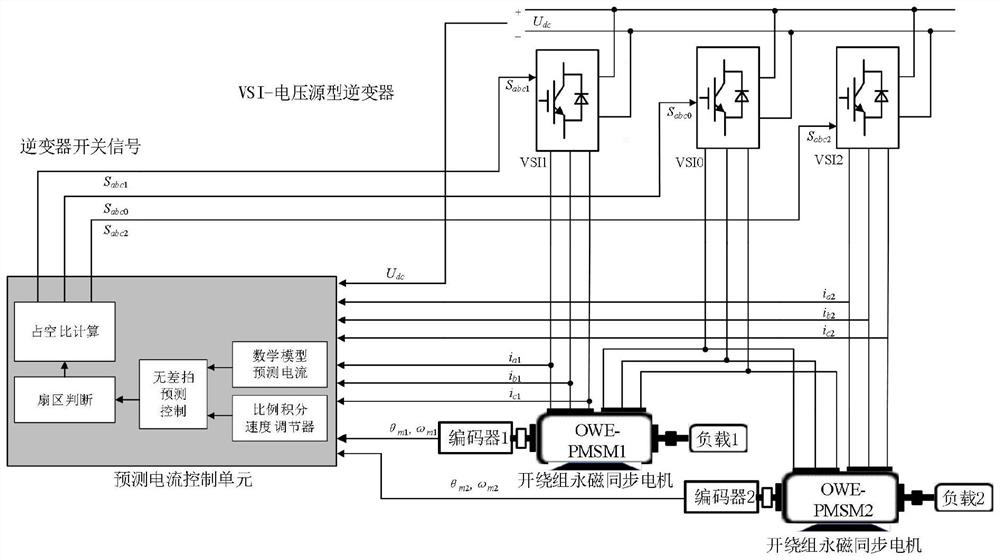

[0015] as attached figure 1 As shown, a three-vector predictive current control method for a semi-centralized open-winding permanent magnet synchronous motor system disclosed in an embodiment of the present invention is characterized in that: the system includes two three-phase open-winding permanent magnet synchronous motors, three Two-level voltage source inverter and predictive current control unit. The three inverters are connected by a common DC bus. Each open-winding motor needs to supply power from the left and right ends at the same time. The two motors are called Motor No. 1 and motor No. 2, the left end of motor No. 1 and the right end of motor No. 2 each use an independent inverter, while the right end of motor No. 1 and the left end of motor No. 2 share a multiplexing inverter, The respective independent inverters are called No. 1 inverter and No. 2 inverter, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com