Industrial Internet of Things for production task plan implementation and control method thereof

An industrial Internet of Things, production task technology, applied in the field of intelligent manufacturing, can solve the problems of difficult to achieve overall control, data interaction errors, difficult to associate workshop or equipment data transmission, etc., to optimize the data processing path, simplify the Internet of Things structure, and facilitate the The effect of independent transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments and the accompanying drawings. as a limitation of the present invention.

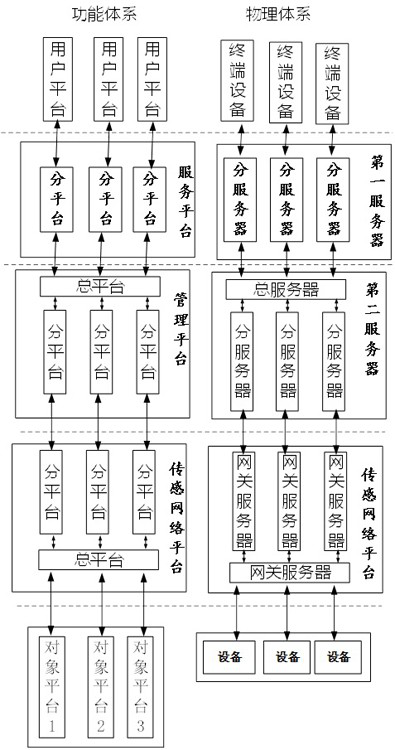

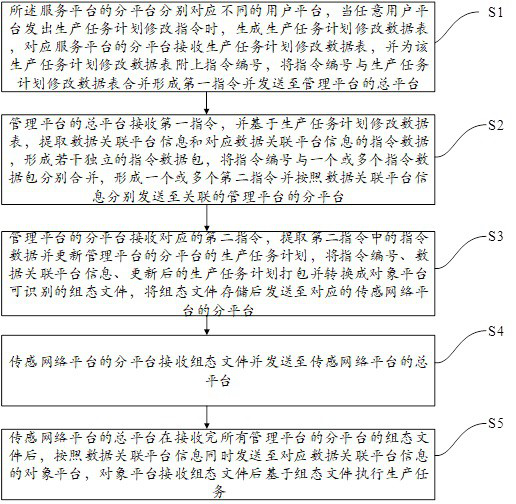

[0054] like figure 1 As shown, the first embodiment of the present invention aims to provide an industrial Internet of Things for the implementation of production task plans, including: a user platform, a service platform, a management platform, a sensor network platform and an object platform that interact in sequence;

[0055] The service platform adopts an independent arrangement, the management platform adopts a front sub-platform arrangement, and the sensor network platform adopts a rear sub-platform arrangement; the independent arrangement means that the service platform is provided with a plurality of independent sub-platforms, A plurality of sub-platforms respectively perform data storage, data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com