Pulse control system with bag breaking positioning function

A pulse control and control system technology, applied in the direction of comprehensive factory control, separation methods, transportation and packaging, etc., can solve the problems of leakage, programming can not monitor the location of dust leakage, etc., to reduce economic losses, reduce software programming and debugging time, The effect of breaking down data silos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

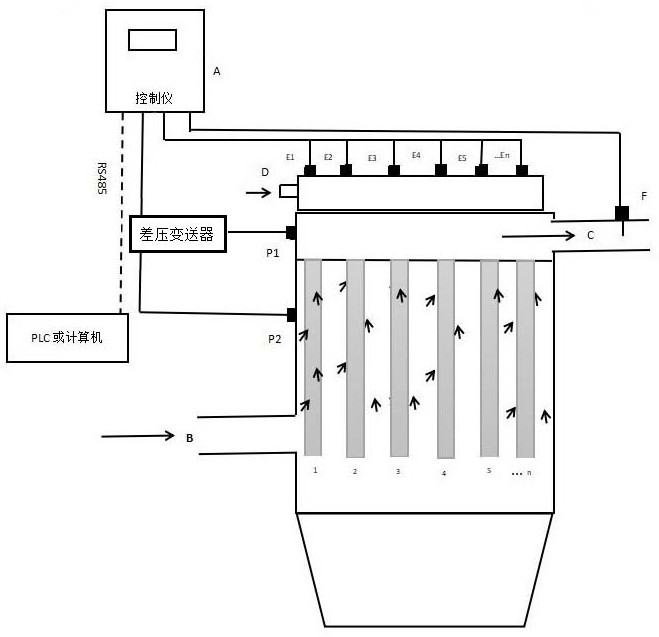

[0027] Example: as figure 1 As shown in the figure, the present invention provides a pulse control system with a broken bag positioning function, including a pulse controller, a factory or workshop-level control system, and a differential pressure transmitter connected to the precipitator gas, respectively connected to the pulse controller. The multiple pulse valves E on the bag, the dust concentration sensor installed at the air outlet of the dust collector; the differential pressure transmitter is respectively connected to the low pressure end P of the differential pressure transmitter installed in the clean air chamber of the dust collector 1 Sampling port and high pressure side P of differential pressure transmitter installed on the dust-carrying side of the precipitator 2 sampling port.

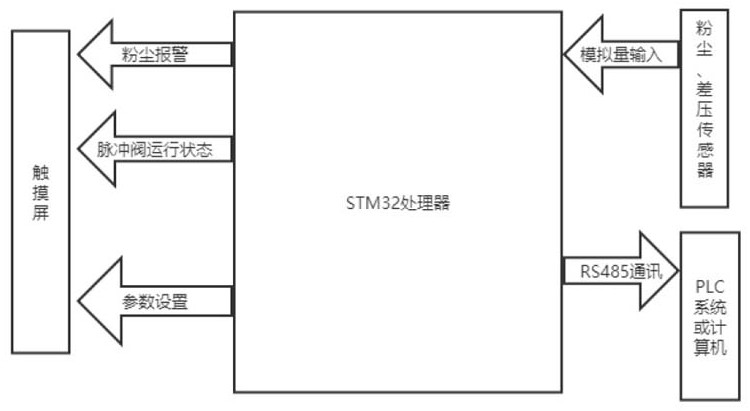

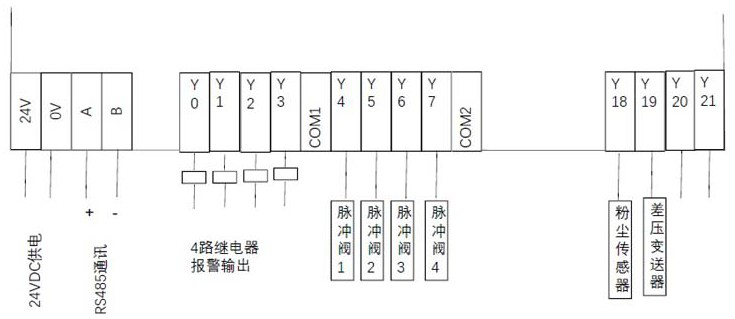

[0028] like figure 2 , 3 As shown, the pulse controller adopts STM32 processor as the data processing controller, and the parameters are modified through the touch screen on the puls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com