Method and device for extracting sulfate by directional crystallization of desulfurization tail liquid through liquid phase catalysis method

A liquid-phase catalysis and directional crystallization technology, applied in the field of environmental engineering, can solve the problems of high sulfuric acid production cost and daily operating cost, difficult to handle, increase the operating cost of coking enterprises, etc., and achieve the effect of crystallizing regulation and cleaning cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

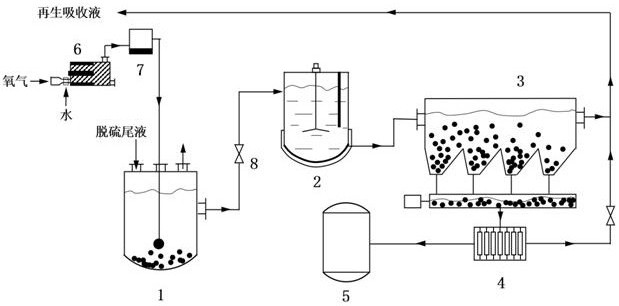

Embodiment 1

[0014] The volume ratio of water and oxygen at the inlet of the semi-wet ozone generator 6 is controlled to be 0.05, the pulse discharge frequency of the device is 150kHz, the voltage is 25kV, the distance between the high voltage electrode and the ground electrode is 30mm, and the water mist oxygen mixture is passed between the two discharge electrodes. The speed is 40m / s. The generated ozone gas is passed into the strong oxidation regeneration device 1 equipped with the HPF method desulfurization tail liquid, and the gas flow rate is controlled to be 180 mL / min. The liquid pump 8 is pumped into the crystallizing tank 2, anhydrous methanol is added (the volume ratio of anhydrous methanol and the solution in the crystallizing tank is 0.6), the pH is adjusted to 4.0, the reaction temperature of the system is 60 ° C, and the stirring speed is 100 rpm. After 5 minutes of reaction , pass part of the crystallization and liquid into the crystallization tank 3, after the crystals are...

Embodiment 2

[0016] The volume ratio of water and oxygen at the inlet of the semi-wet ozone generator is controlled to be 0.08, the pulse discharge frequency of the device is 200 kHz, the voltage is 45 kV, and the distance between the high-voltage electrode and the ground electrode is 30 mm. The speed is 50m / s. The generated ozone gas is passed into the strong oxidation regeneration device 1 equipped with the ADA method desulfurization tail liquid, and the control gas flow is 230 mL / min. The liquid pump 8 is pumped into the crystallizing tank 2, acetone is added (the volume ratio of acetone to the solution in the crystallizing tank is 0.8), the pH is adjusted to 6.5, the reaction temperature of the system is 50 ° C, and the stirring speed is 230 rpm. The liquid is passed into the crystallization tank 3. After the crystals are fully grown and precipitated in the crystallization tank 3, the crystals enter the crystal mud storage tank for preliminary liquid-solid separation and then pass into...

Embodiment 3

[0018] The volume ratio of water and oxygen at the inlet of the semi-wet ozone generator is controlled to be 0.1, the pulse discharge frequency of the device is 300 kHz, the voltage is 65 kV, and the distance between the high-voltage electrode and the ground electrode is 30 mm. The speed is 60m / s. The generated gas is passed into the strong oxidation regeneration device 1 equipped with the complex iron method desulfurization tail liquid, and the control gas flow rate is 430mL / min. 8 Pump into the crystallizing tank 2, add acetone (the volume ratio of acetone to the solution in the crystallizing tank is 0.8), adjust the pH to 8.0, the reaction temperature of the system is 30 ° C, and the stirring speed is 400 rpm. into the crystallizing tank 3, after the crystals in the crystallizing tank 3 are fully grown and precipitated, the crystals enter the crystal mud storage tank for preliminary liquid-solid separation, and then pass into the filter device for further filtration to obta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap