Antiskid space cloth and preparation process thereof

A preparation process and space technology, applied in the field of anti-slip space cloth and its preparation technology, can solve the problems of complex production process of anti-slip space cloth, many materials used in anti-slip space cloth, good mechanical properties, etc., and achieve complex production process and quality effect Guaranteed, high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

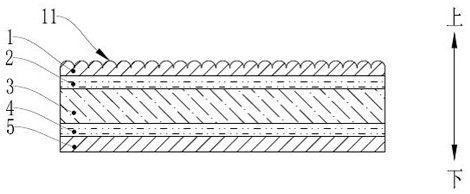

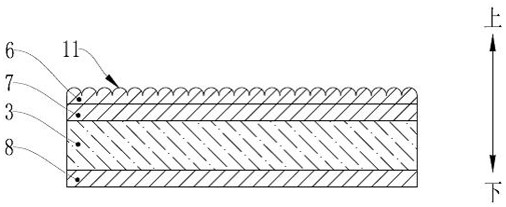

[0034] A preparation process of a non-slip space cloth, comprising the following steps:

[0035] Step A, ironing the space cloth after rolling, coating the adhesive glue on the upper surface and the lower surface of the space cloth respectively, and drying after coating;

[0036] Step B, place PVC film on the upper surface and lower surface of the space cloth respectively, and carry out high temperature lamination;

[0037] Step C, embossing on the surface of the PVC film located on the upper surface of the space cloth, and cooling to obtain a non-slip space cloth;

[0038] The raw materials of the PVC film include PVC powder, general-purpose plasticizer, stabilizer, liquid styrene-butadiene rubber and heavy calcium;

[0039] The raw materials of the adhesive include PVC paste resin, general-purpose plasticizer, stabilizer, adhesive, diluent and calcium powder.

[0040] In the present invention, the adhesive glue is respectively applied on the upper surface and the lower sur...

Embodiment 1

[0074] A preparation process of a non-slip space cloth, comprising the following steps:

[0075] Step A, ironing the space cloth after rolling, coating the adhesive glue on the upper surface and the lower surface of the space cloth respectively, and the coating weight of the adhesive glue is 200g / m 2 , drying after coating, drying temperature is 145 ℃;

[0076] Step B, place PVC film on the upper surface and the lower surface of the space cloth respectively, the thickness of the PVC film is 0.35mm, and the high temperature lamination is performed at 170°C;

[0077] Step C, embossing on the surface of the PVC film located on the upper surface of the space cloth, and cooling to obtain a non-slip space cloth;

[0078] According to the calculation of parts by weight, the raw materials of the PVC film are 80 parts of PVC powder, 40 parts of general-purpose plasticizer, 0.8 part of stabilizer, 2 parts of liquid styrene-butadiene rubber, 5 parts of heavy calcium, and 5 parts of low ...

Embodiment 2

[0085] Compared with Example 1, in Example 2, according to the parts by weight, the raw materials of the PVC film are 90 parts of PVC powder, 50 parts of general-purpose plasticizer, 2.5 parts of stabilizer, 5 parts of liquid styrene-butadiene rubber, and 20 parts of heavy calcium. parts, 10 parts of low temperature resistant plasticizer, 0.2 part of antioxidant, 0.5 part of ultraviolet absorber and 5 parts of colorant. Calculated in parts by weight, the raw materials of the adhesive are 90 parts of PVC paste resin, 90 parts of general-purpose 85 parts of plasticizer, 2 parts of stabilizer, 5 parts of adhesive, 8 parts of diluent and 10 parts of calcium powder, the rest of the raw materials and the preparation method are the same as those in Example 1, to obtain a non-slip space cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transverse tensile strength | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com