Rapid recovery device for offshore oil pollution

A technology of offshore oil and recovery equipment, which is applied to the cleaning of open water surfaces, construction, water conservancy projects, etc., and can solve the problems of inability to automatically adjust the collection depth, inability to collect and separate oil at the same time, and low oil collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

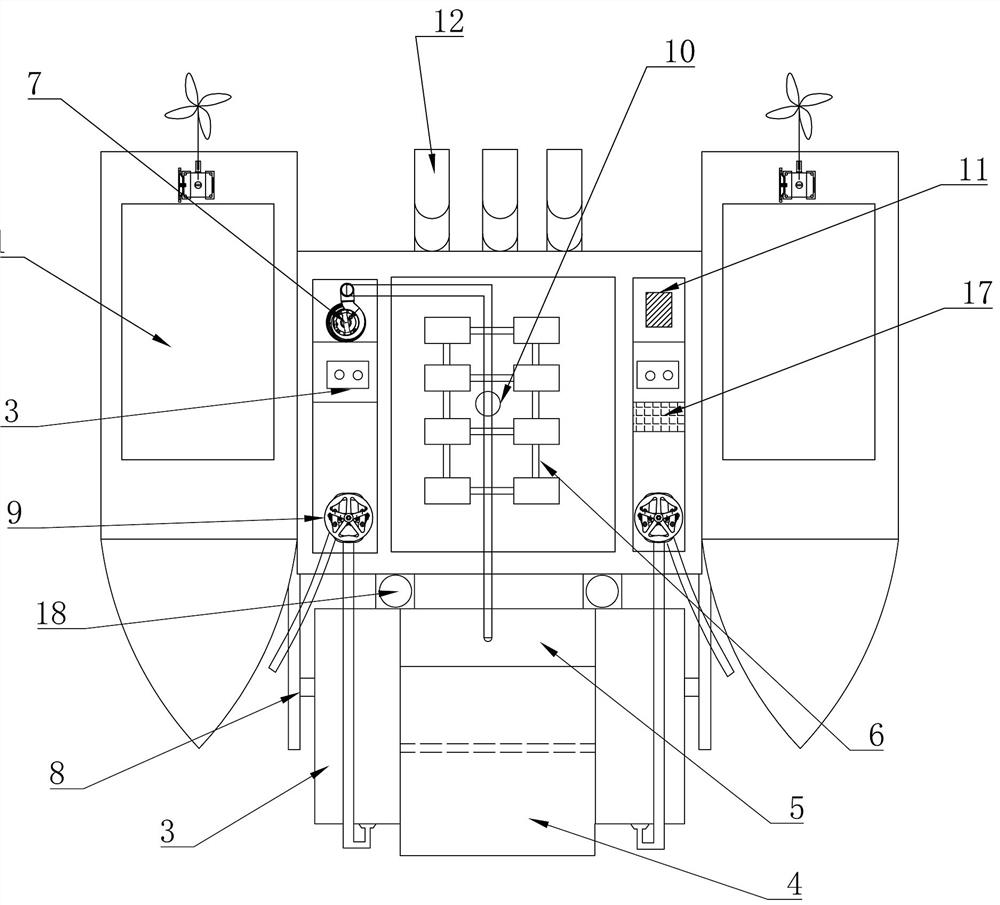

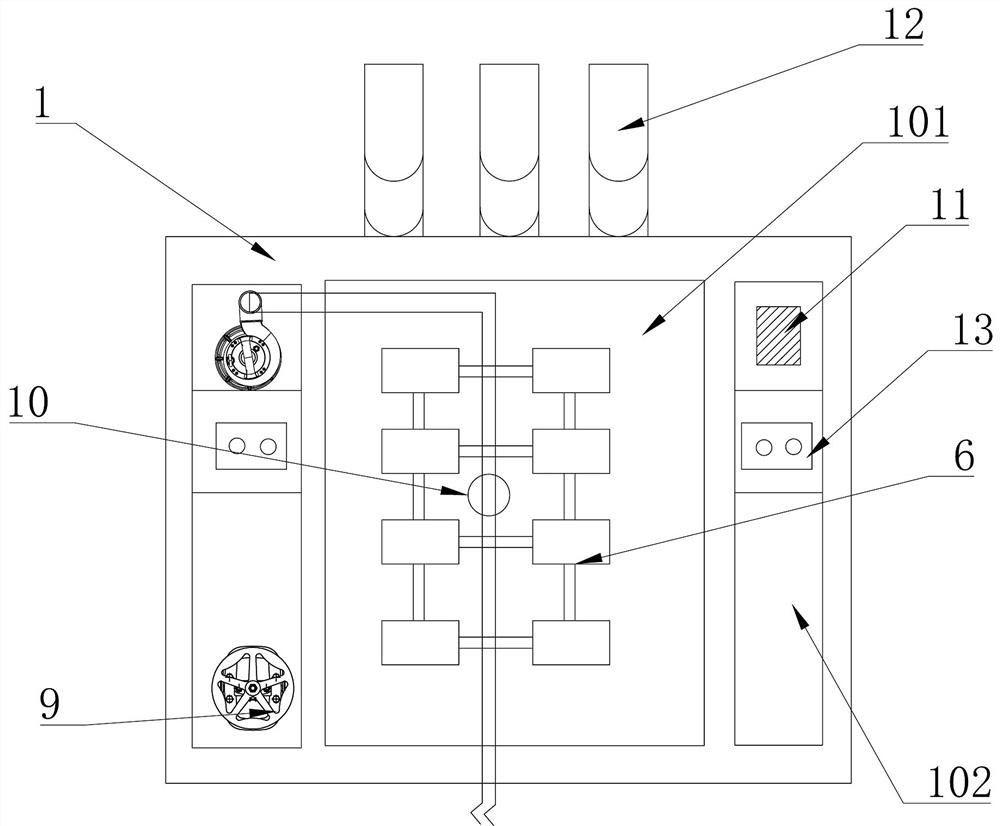

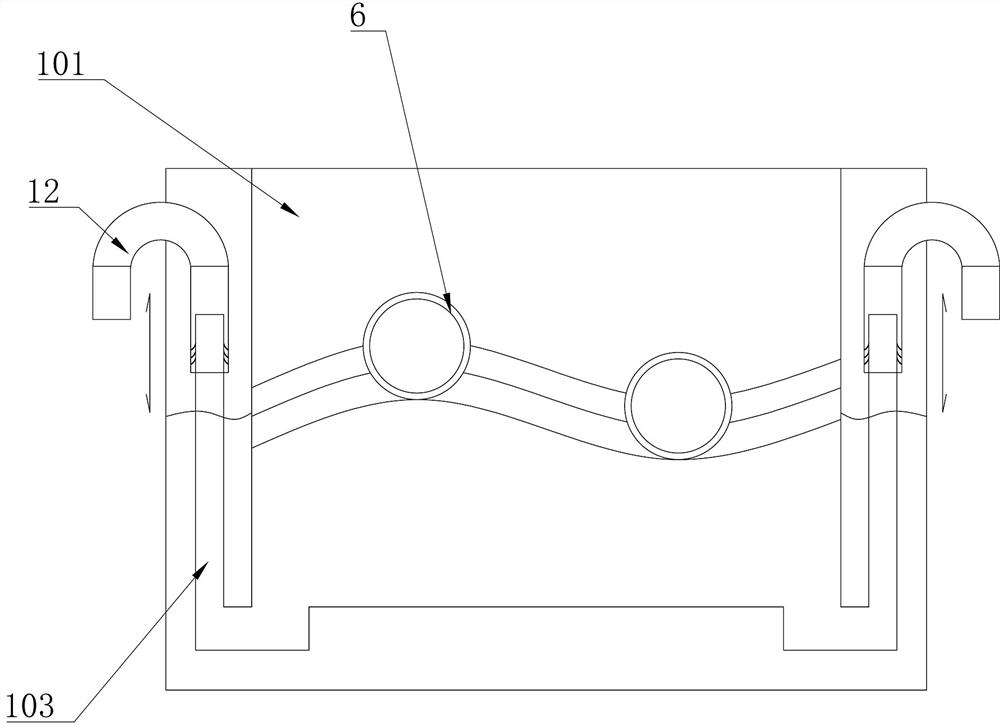

[0049] like Figure 1-12 , the rapid recovery device for marine oil pollution, including a hull 1, the hull 1 is connected to the oil storage tank 101, the hull 1 is connected to the scraper 4 through a lifting mechanism, the scraper 4 is arranged inclined, and the front end of the scraper 4 is used for collecting For the floating oil stains, the rear end of the scraper 4 is provided with an oil collecting tank 5 , and the oil collecting tank 5 is communicated with the oil storage bin 101 through the oil pump 7 . With this structure, the liquid level sensor 2 in the buoy 3 is used to feed back the water level in the buoy 3 . The scraper 4 is inclined relative to the water surface, the water-facing end of the scraper 4 is lower, and the water-reversing end is higher, and one side of the scraper 4 is connected with the oil collecting tank 5, so that when the water-facing end of the scraper 4 is in the oil stain, When the hull 1 runs at a lower speed, the oil can also rush up th...

Embodiment 2

[0074] With reference to Embodiment 1, it is further explained that when the hull 1 is a single ship structure, the hull 1 has a simple structure, less investment in the overall device, low cost, and convenient operation.

[0075] When the hull 1 is a double-vessel structure, the double-vessel is fixedly connected, the overall structure is not easy to roll over, and there are often large winds and waves in the ocean, and the hull 1 needs to have high stability. In the path planning of oil pollution collection, the hull 1 structure needs to have a small turning radius to implement the "S"-shaped intelligent path planning scheme. The two propellers of the catamaran can ensure a very small turning radius by rotating forward and reverse at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com