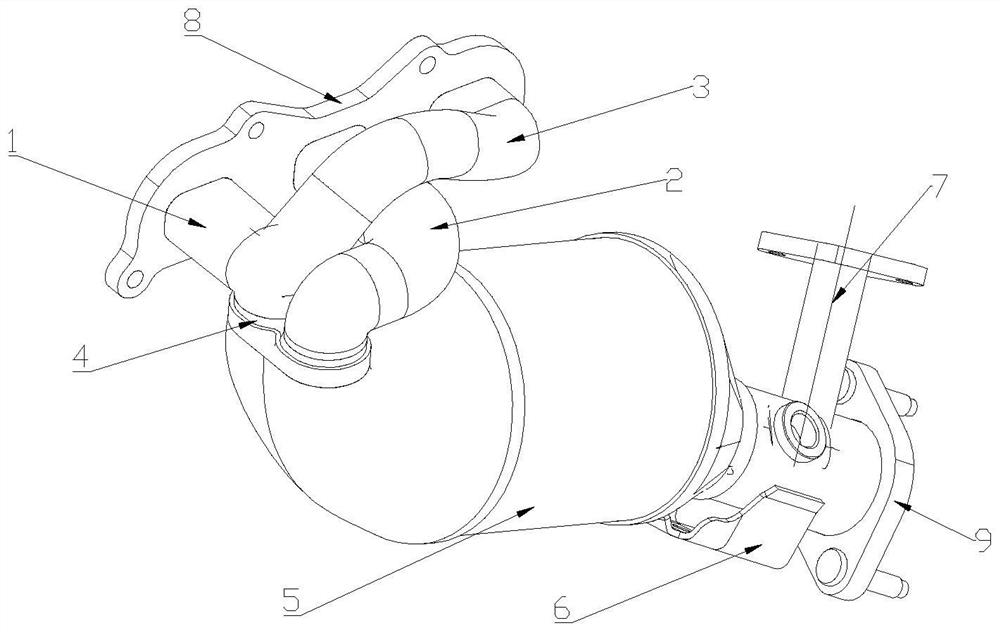

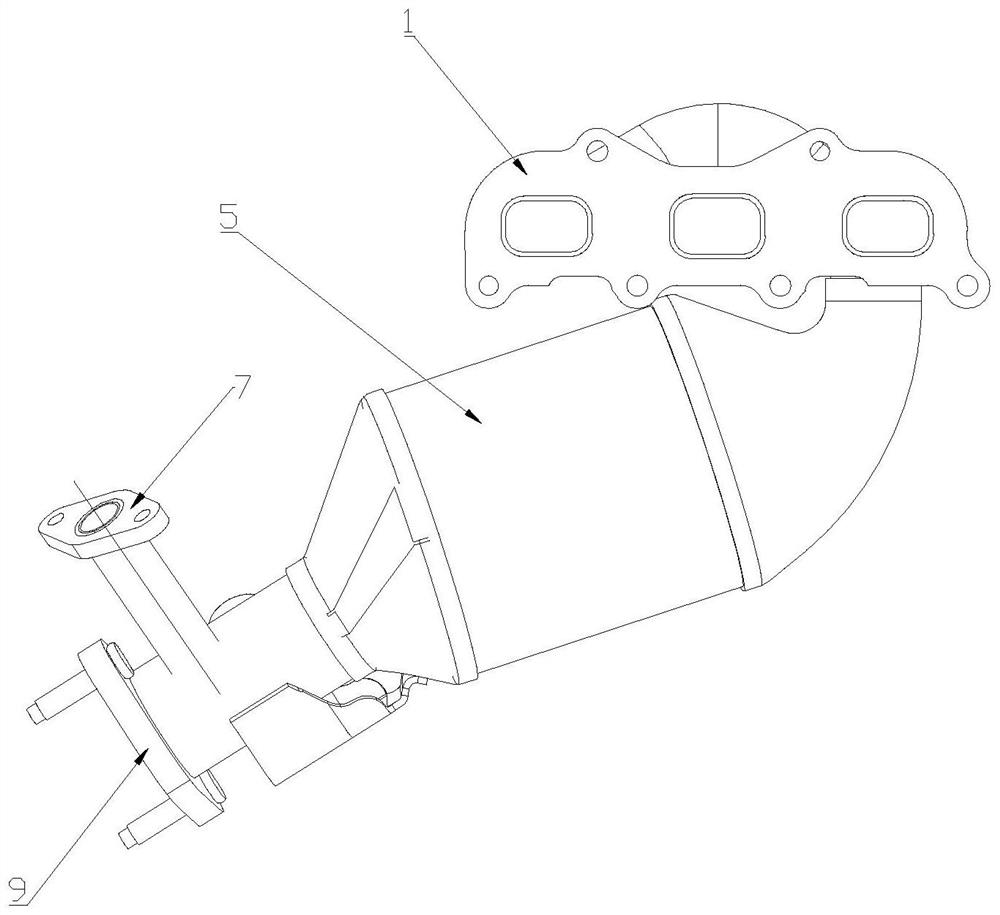

Upright rear-drive tight coupling type exhaust manifold

An exhaust manifold and integrated exhaust manifold technology, applied in exhaust devices, air quality improvement, combustion engines, etc., can solve the problems of reducing engine torque and power, affecting the smooth discharge of exhaust gas, etc., to improve power and torque , The effect of facilitating the layout of the whole machine and preventing airflow disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the purpose, structure and function of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings.

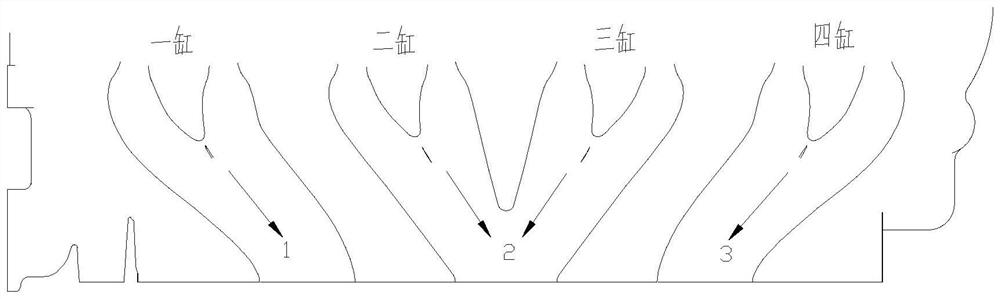

[0014] The exhaust manifold is matched with an upright rear-drive four-cylinder four-stroke engine. The working sequence of one-three-four-two cylinders makes the exhaust strokes of the two and three cylinders not adjacent, thus ensuring that the exhaust gases of the two and three cylinders converge. Without interfering with each other, there is sufficient exhaust time, such as image 3 As shown in the figure, the exhaust manifolds of the second and third cylinders are integrated into the cylinder head. Under the premise of effectively avoiding the mutual interference of the exhaust air flow, the high temperature of the exhaust manifold can quickly heat the antifreeze when the car is cold, which greatly reduces the hot car. time and improve thermal efficiency.

[0015] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com