Heating wallboard temperature control system

A technology of temperature control system and wall panel, which is applied in the direction of electric heating system, heating system, heating method, etc., can solve the problems of uncomfortable feeling of human body, difficulty in uniform heating, low heating efficiency, etc., and achieve high control precision, simple structure, The effect of temperature control stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

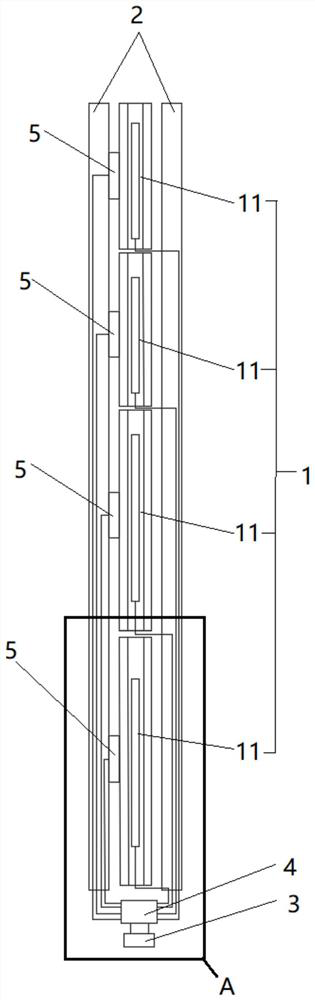

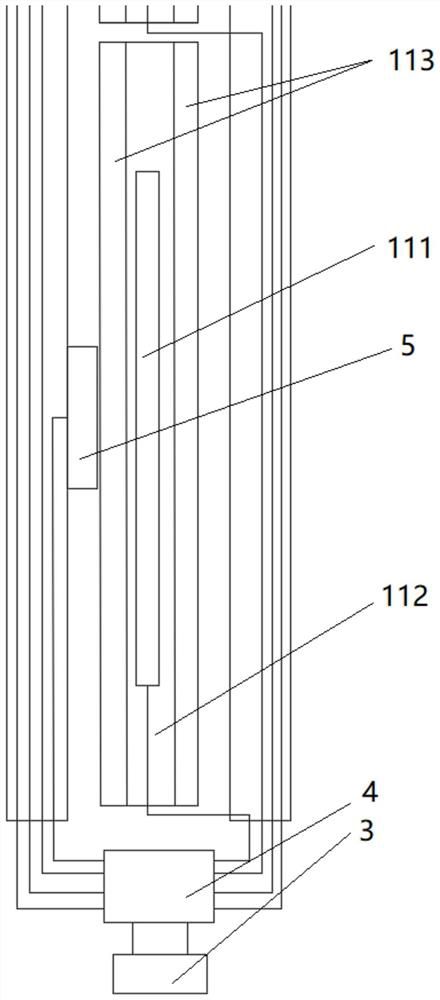

[0036] like figure 1 and figure 2 As shown, the present invention provides a heating wall panel temperature control system, including a heating wall panel assembly and a power supply assembly, the heating wall panel assembly includes a heating film array 1 and a wall panel surface layer 2 respectively disposed on both sides of the heating film array 1, The heating film array 1 is formed by a plurality of heating film units 11 arranged according to a set rule. The heating film unit 11 includes an electrode plate 111, a semiconductor heating layer 112 and an encapsulation layer 113, and the power supply assembly includes an interconnected power supply 3 and a controller 4. , the power supply 3 is respectively connected with the electrode plate 111 of each heating film unit 11, and the controller 4 controls the power supply 3 to supply power to each heating film unit 11 with different average powers, so that the heating film array 1 gradually changes from low to high temperature...

Embodiment 2

[0042] like Figure 1-Figure 3 As shown, in this embodiment, the power supply 3 is controlled to supply power to each heating film unit 11 with different average powers through the temperature feedback of each heating film unit 11 and the control power-on duration. At this time, the temperature control system of the present invention also includes: The temperature sensors 5 connected to the controller 4 are provided in a plurality and correspond to the heating film units 11 one-to-one, and are respectively arranged between each heating film unit 11 and the wallboard surface layer 2 , and the others are the same as those in the first embodiment.

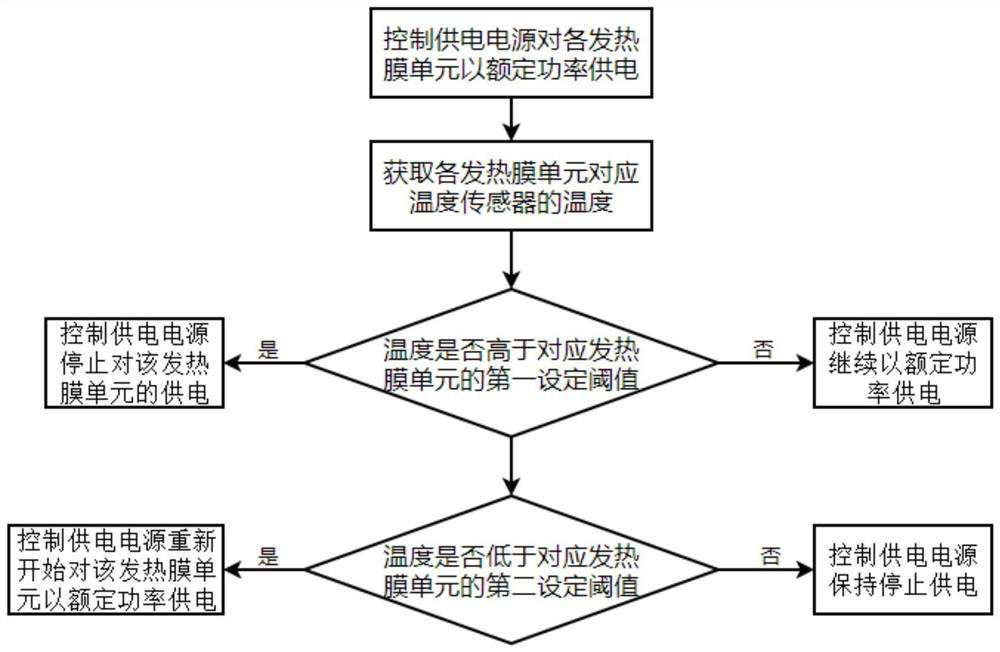

[0043] The control steps specifically include:

[0044] S11: control the power supply 3 to supply power to each heating film unit 11 with rated power;

[0045] S12: Acquire the temperature detected by the temperature sensor 5 corresponding to each heating film unit 11, and determine whether the temperature detected by each temperatur...

Embodiment 3

[0051] In this embodiment, the power supply 3 is controlled to supply power to each heating film unit 11 with different average powers through temperature feedback, time control and power output proportional control.

[0052] The control steps specifically include:

[0053] S21: control the power supply 3 to supply power to each heating film unit 11 with rated power;

[0054] S22: Acquire the temperature detected by the temperature sensor 5 corresponding to each heating film unit 11, and determine whether the temperature detected by each temperature sensor 5 reaches the set temperature value corresponding to the heating film unit 11, and if so, control the power supply 3 to set the output Proportionally supply power to the heating film unit 11, and execute step S23, otherwise control the power supply 3 to continue to supply power with rated power;

[0055] S23: Acquire the temperature detected by the temperature sensor 5 corresponding to each heating film unit 11, and determi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com