Non-water crosslinkable composition

A resin composition and compound technology, applied in the field of granular polyurea compounds and resin compositions, can solve the problems of limited final gloss control, coating block defects, difficult control of molecular weight and urea bond number, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

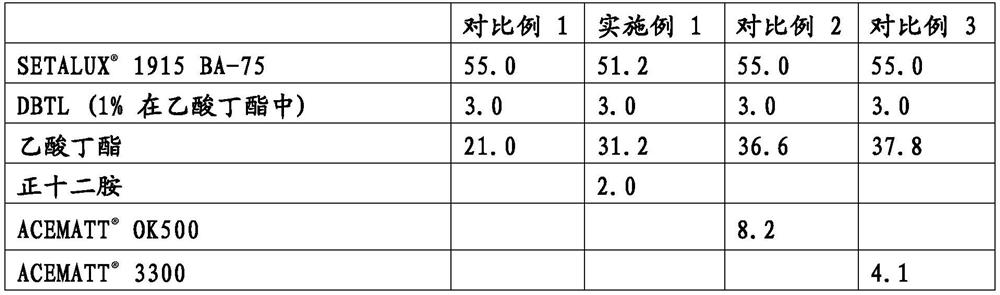

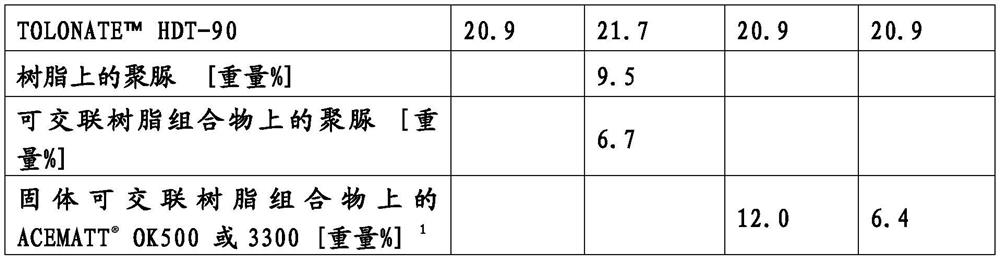

[0279] In the table below, Examples are abbreviated as Ex and Comparative Examples are abbreviated as Comp Ex.

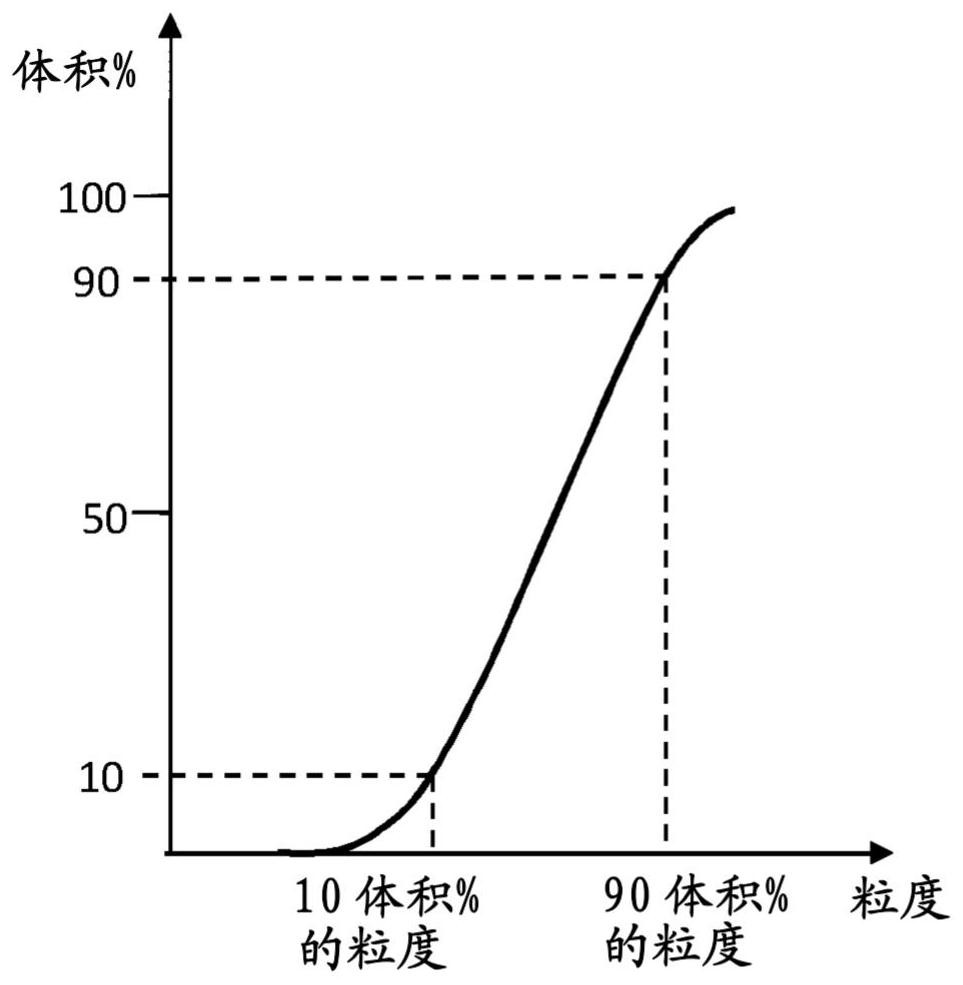

[0280] Formulations were prepared according to Table 1. will exclude TOLONATE TM All components except HDT-90 are mixed. Subsequently, TOLONATE was added slowly while stirring at 370-420 rpm using a propeller stirrer TM HDT-90. The resulting average particle size of the polyurea adduct of Example 1 was 40 μm, the cumulative volume percentage of particles smaller than 10 μm was 10%, and the cumulative volume percentage of particles larger than 20 μm was 82%. For Example 1, (PS at 90 vol% / PS at 10 vol%) = 4.9.

[0281] Table 1

[0282]

[0283]

[0284] 1 Calculated as: [( OK500 or 3300 weight) / ( 1915BA-75 WEIGHT OF NON-VOLATILE PART + TOLONATE TM Weight of non-volatile part of HDT-90+ OK500 or 3300 weight)]x100

[0285] The coating was applied to glass and the tack time and Persoz hardness were measured. The paint was also applied over a black so...

Embodiment B

[0290] Film-forming resins containing polyurea matting agents were prepared according to Table 3, the ingredients of which are listed under "Polyurea-Containing Polyols". Here, the particle size is adjusted according to the process conditions. More specifically, the amount of benzylamine is pre-dissolved in the reactor in 1915 Polyols, followed by TOLONATE TM HDT-90 (diluted to 50% solids with butyl acetate) was added to the reactor while using an anchor stirrer at 21-32°C at about 400 rpm (Examples 2 and 4 and Comparative Example 5) or 125 rpm ( Example 3 and Example 5 and Comparative Example 4) stirring. Subsequently, a crosslinkable composition was prepared by adding the remaining components shown in Table 3 under "Coating". All samples were formulated at the same solids content of 58 wt%.

[0291] table 3

[0292]

[0293] *In this experiment, TOLONATE was TM HDT-90 was diluted from the normal 90 wt% solids delivery form to 50 wt% solids.

[0294] The paint was ...

Embodiment C

[0299] A film-forming resin comprising a polyurea matting agent and optional dispersant was prepared according to Table 5a. The stated amount of benzylamine was pre-dissolved in the reactor 1915 Polyols, followed by TOLONATE TM HDT-90 (diluted to 60% solids with butyl acetate) was added to the reactor while stirring at about 125 rpm using an anchor stirrer at 20-30°C. The particle size distribution is then determined. The film-forming resin containing the polyurea adduct was diluted to 53% solids and then the viscosity was measured. In addition, crosslinkable compositions were prepared by adding components as shown in Table 5b. All samples were formulated at the same solids content of 55% of the crosslinkable composition.

[0300] Table 5a

[0301]

[0302]

[0303] *In this experiment, TOLONATE was TM HDT-90 was diluted from the normal 90 wt% solids delivery form to 60 wt% solids.

[0304] Table 5b

[0305]

[0306] The crosslinkable compositions in Tables 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com