Method for manufacturing positive electrode active material for lithium secondary battery and positive electrode active material for lithium secondary battery manufactured thereby

A positive electrode active material, lithium secondary battery technology, applied in the direction of active material electrodes, battery electrodes, lithium batteries, etc., can solve the problems of low thermal stability, battery rupture, performance degradation of positive electrode materials, etc., to improve conductivity and prevent condensation Gelling, effects that improve input/output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0096] Hereinafter, the present invention will be described in detail with reference to the embodiments. However, the embodiments according to the present invention may be modified into other various forms, and the scope of the present invention should not be construed as being limited to the embodiments described below. The embodiments of the present invention are provided to more fully describe the present invention to those skilled in the art.

Embodiment 1

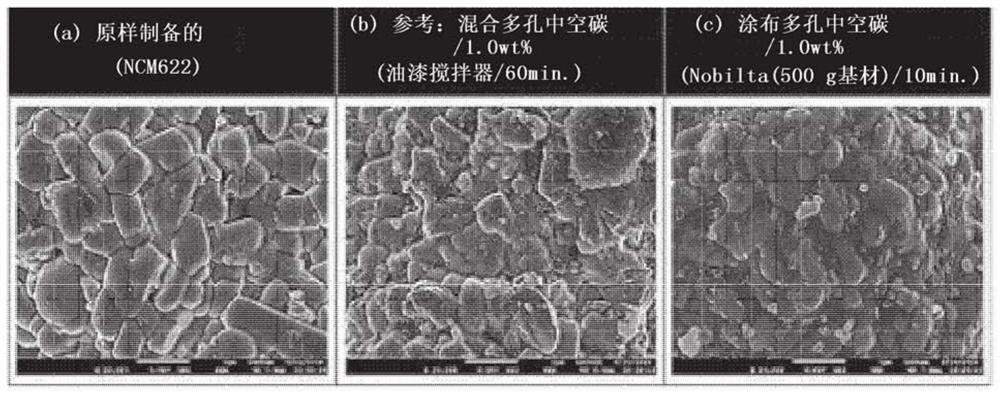

[0099] will be composed of LiNi 0.6 CO 0.2 Mn 0.2 O 2 The indicated lithium transition metal oxide and carbon black having the hollow structure of the specifications in Table 1 below were introduced into a paint stirrer (1400Al classic stirrer, Red Devil Co., Ltd), and then mixed for 60 minutes so that the carbon black was relative to 500 g. The lithium transition metal oxide was 1 wt %, so that the transition metal oxide and the carbon black of the hollow structure were uniformly dispersed.

[0100] The above mixture was introduced into a mechanofusion apparatus (nobilta, Hosokawa Micron Co., Ltd), and then processed at 3000 rpm for 10 minutes to produce a positive electrode active material in which a carbon coating layer with a thickness of 200 nm was formed on the lithium transition metal oxide.

Embodiment 2

[0102] Except that the mixing was carried out in such a way that the carbon black was 1 wt % with respect to 200 g of the lithium transition metal oxide, in the same manner as in Example 1, a carbon black having a thickness of 250 nm was produced in the same manner as in Example 1. Carbon-coated cathode active material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com