Woolen cloth garment processing technology and intelligent woolen cloth garment processing equipment

A processing technology and intelligent processing technology, which is applied in the field of garment processing, can solve the problems of complex preparation process, low production efficiency, and large thickness of seams, and achieve the effect of simple production method, high production efficiency and full sense of shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

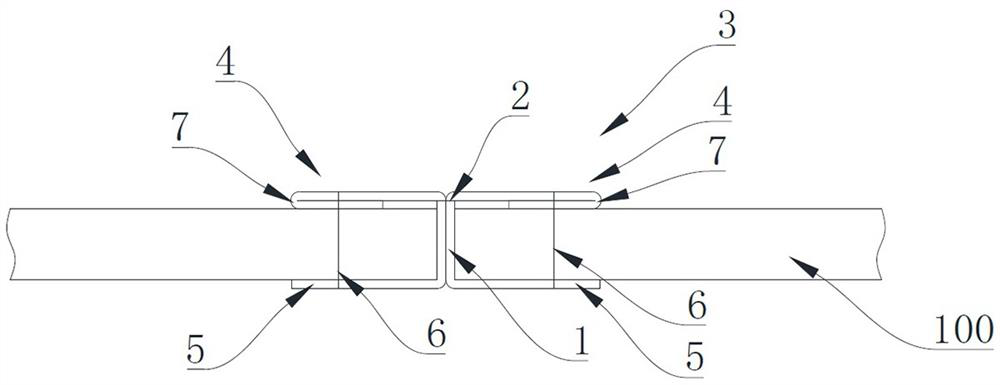

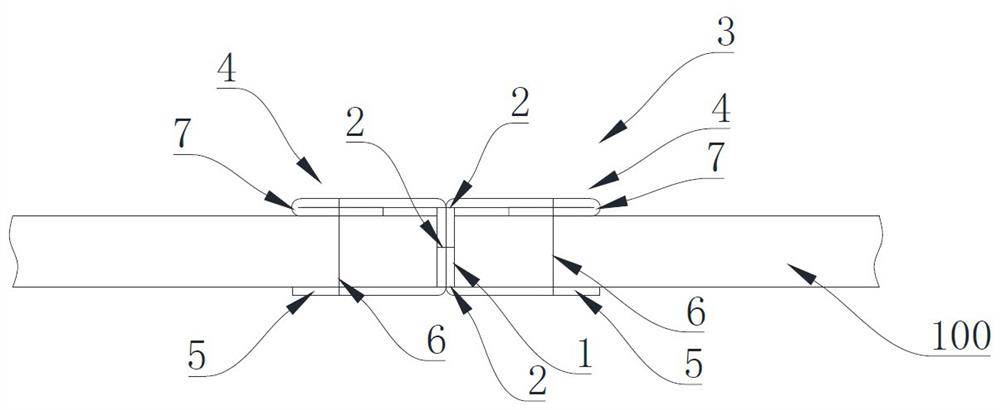

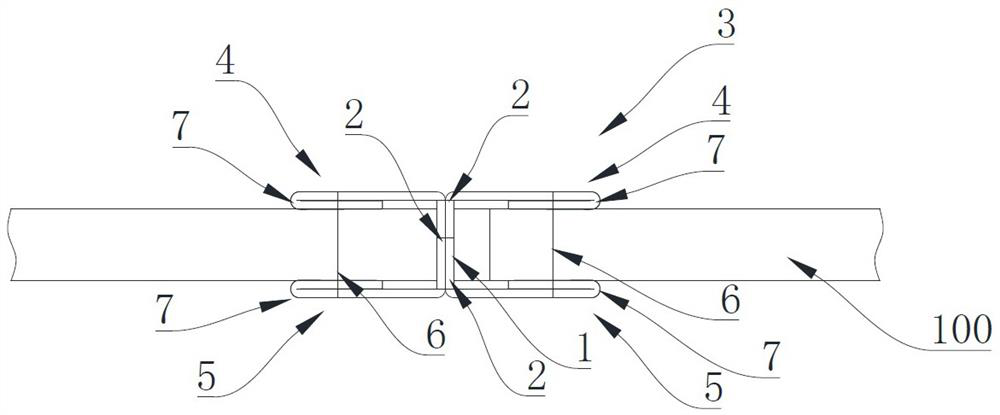

[0057] The present embodiment is a kind of woolen garment processing technology, such as figure 1 As shown, it includes the step of splicing the fabric pieces (100), and the step includes:

[0058] (1) Two thin cut pieces 1 are sewn to form a first fixed seam 2, and a splicing piece 3 is made. The second seam 5;

[0059] Wherein, in this embodiment, there is no requirement for the material of the thin cut piece 1, as long as the thickness is thin and the woolen cut piece 100 can be stably spliced together; On both sides, two pieces of first seam heads 4 and two pieces of second seam heads 5 are formed;

[0060] (2) The splicing piece 3 is placed between the two pieces of woolen material cuttings 100, so that the two first seam heads 4 are turned to the outer sides of the two pieces of woolen material cuttings 100 respectively, so that the two second seam heads 5 Turn over to the inner sides of the two pieces of woolen fabric pieces 100 respectively, and sew and fix the fi...

Embodiment 2

[0067] The present embodiment is a kind of woolen garment processing technology, such as Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, it includes the steps of making the three-dimensional pocket 8 on the cloth piece 100, and the step includes:

[0068] (a) The bag body 200 with the inner pocket 201 is made by using the lining cloth 9 and the lining cloth 10, and at least the side of the lining cloth 9 facing away from the lining cloth 10 has a double-sided lining 11;

[0069] The lining cloth 9 and the lining cloth 10 may be bonded to form the bag body 200 through the double-sided lining 11, or the bag body 200 may be formed as follows: Figure 5 As shown, the bag body 200 is formed by sewing the sewing thread, and a U-shaped third fixed seam 12 is formed between the lining cloth 9 and the inner cloth 10;

[0070] (b) Cut out the outer pocket 300 on the cloth cut piece 100 , place the bag body 200 under the cloth material cut piece 100 , and make the position o...

Embodiment 3

[0075] like Figure 8 and Figure 11 As shown, the present embodiment is a kind of intelligent processing equipment for woolen clothing, the equipment includes a frame 15, and the frame 15 is provided with a conveying platform 16 for conveying the woolen pieces 100. The conveying platform 16 is a reciprocating conveyor belt. 17, the operation of the conveyor belt 17 is driven by the rotation of the conveyor roller 18 driven by the motor.

[0076] Above the conveying platform 16, there is a molding mechanism 19 for making the prefabricated pockets on the wool fabric pieces 100 into three-dimensional pockets 8, and a molding mechanism 19 for fixing the wool fabric cutting pieces 100 on the conveying platform 16 for modeling by the modeling mechanism 19. The material pressing mechanism 20; the discharge end of the conveying platform 16 is connected to at least one sewing machine 21, and the sewing machine 21 is used for finishing the three-dimensional pockets 8 on the woolen fab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com