Flexible array type pressure sensor and preparation process

A pressure sensor and flexible array technology, applied in the sensor field, can solve the problems such as the inability of one-to-one correspondence between the sensor unit and the detection curve, inaccurate fault location, and few points, and achieve simple and convenient operation, high sensitivity and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

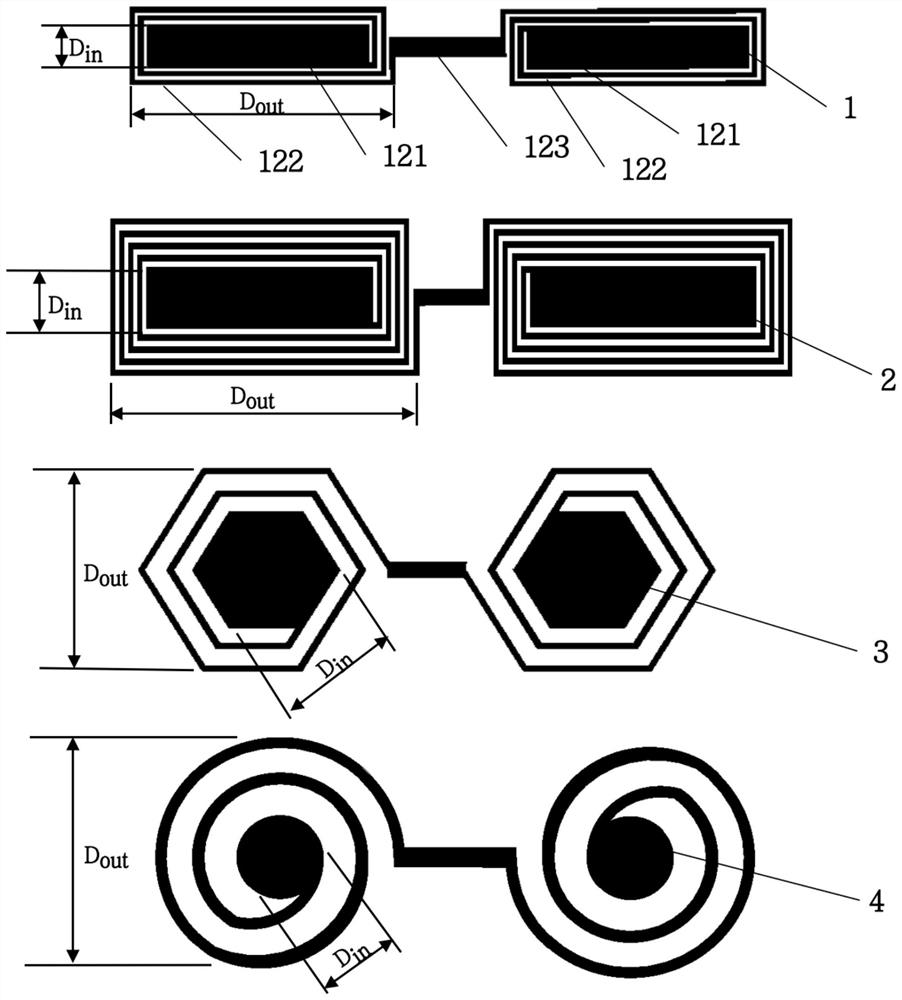

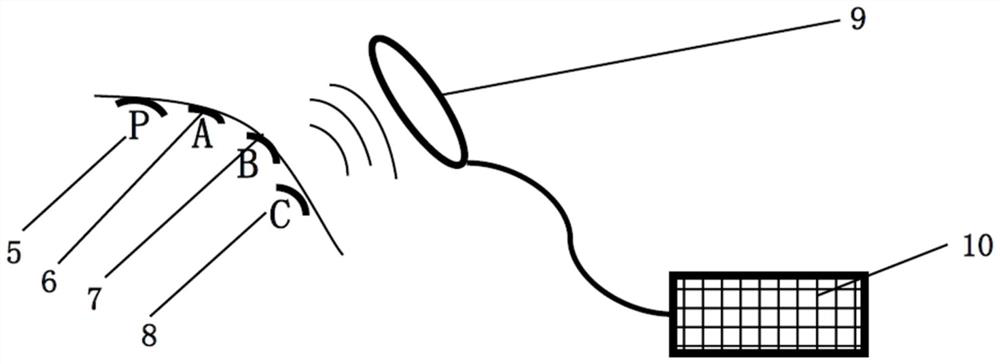

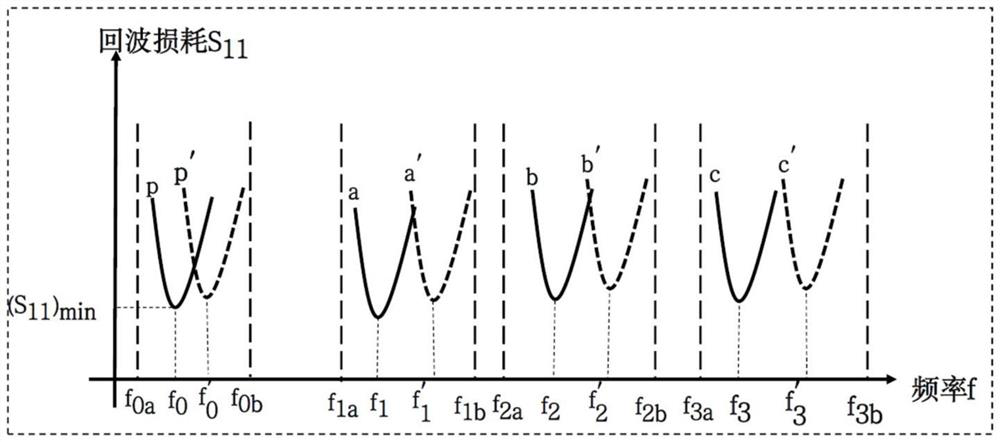

[0058] Example: as figure 1 and Figure 7 As shown, the present invention provides a flexible array pressure sensor, comprising a flexible substrate 11 and four arrayed LC resonant circuits arranged on the flexible substrate 11, each LC resonant circuit includes an inductance coil 122 and a capacitor, the capacitor It includes a pair of capacitor plates 121 and a compressible dielectric layer 13 between the two capacitor plates 121; by changing the shape of the inductance coil 122, the number of inductance turns and the area of the capacitor plates 121, each LC resonates for the same pressure environment. The circuit constitutes a sensor unit, and a plurality of sensor units are in different resonant frequency ranges.

[0059] The LC resonant circuit includes a flexible circuit 12 processed on a flexible substrate 11 and a compressible dielectric layer 13 covering the flexible circuit 12. The flexible circuit 12 includes two capacitor plates 121 surrounding each capacitor p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com