Drilling, milling and cutting device in underwater pipe and using method of drilling, milling and cutting device

A technology of cutting device and cutting device, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of inability to install equipment, inability to back up plates, high equipment, etc., and achieve simple structure, precise strength, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

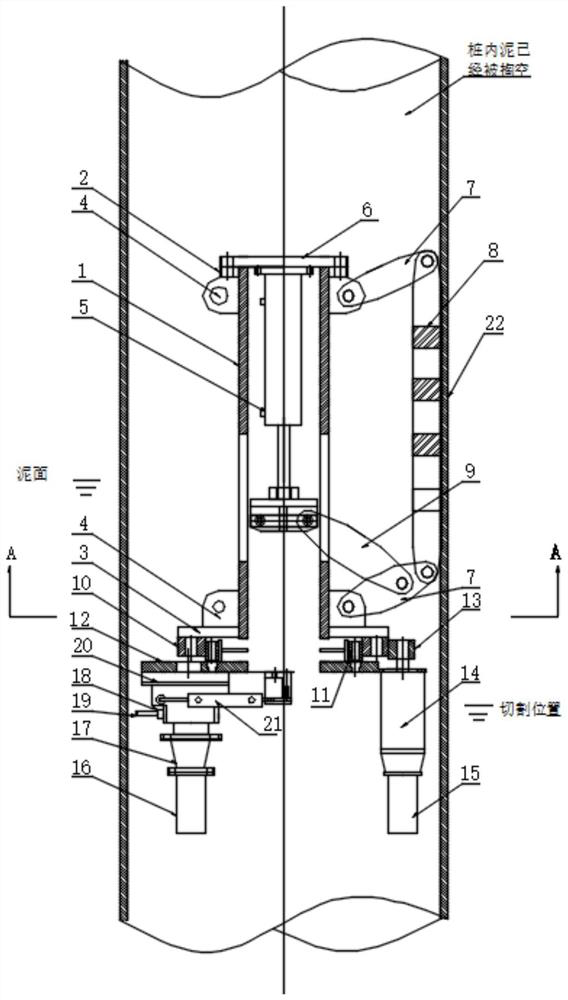

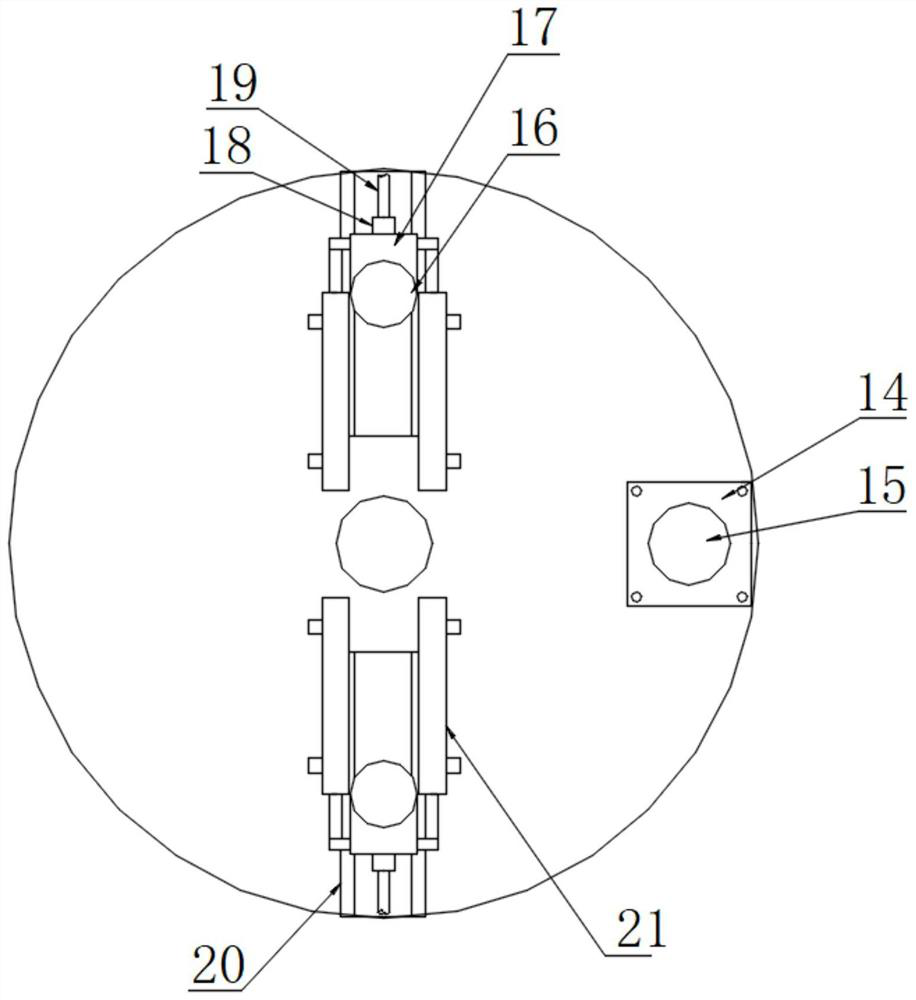

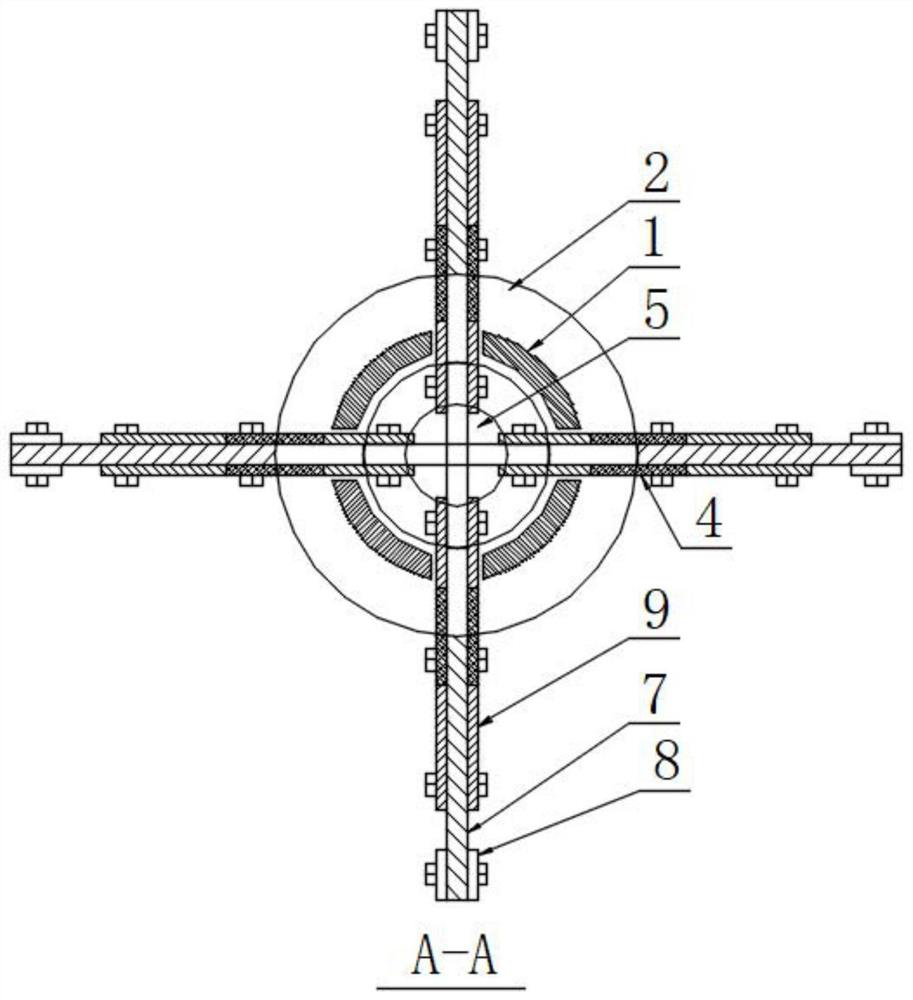

[0050] like Figure 1-3As shown, an underwater pipe inner drilling, milling and cutting device is composed of upper and lower layers, the upper layer is a fixing device, and the lower layer is a cutting device and a rotating device. The fixing device is composed of the main components such as the supporting hydraulic cylinder 5, the supporting short arm 7 controlled by the telescopic control of the supporting hydraulic cylinder, the upper and lower flanges, the base flange 6 and the main structure steel pipe 1. The fixing device is made of a seamless steel pipe as the main structure. (The steel pipe is a structure with a fixed support hydraulic cylinder and a support short arm and is integrated with the upper and lower flanges), the steel pipe is notched every 90°, the main structure steel pipe 1 has a built-in support hydraulic cylinder 5, and the upper and lower ends of the steel pipe are welded respectively. Flange 2 and lower flange 3, the top surface of the upper flange 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com