Preparation method of surface metal-based composite gradient material

A gradient material and surface metal technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of easy segregation, high production cost, waste of particles, etc., to achieve excellent surface formability, improved production efficiency, Backfill Timely Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment includes the following steps:

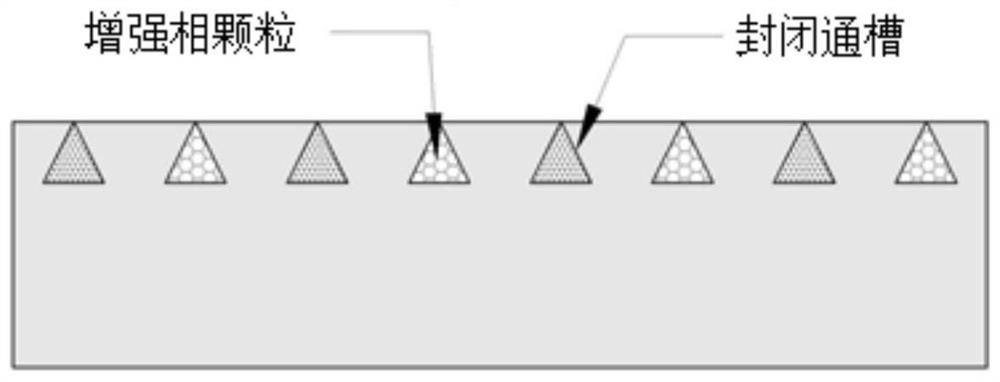

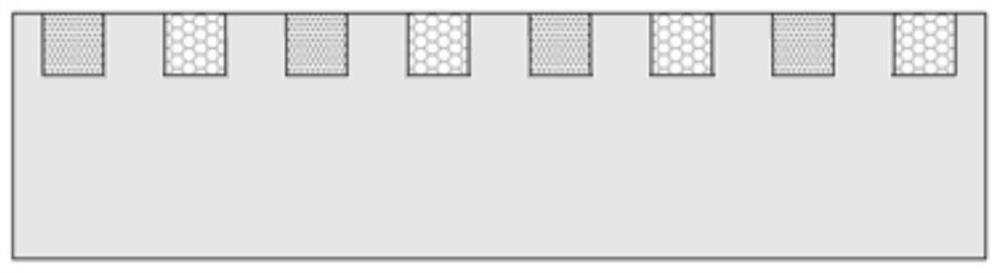

[0050] Step 1, using wire cutting to open a closed through slot inside the metal substrate to obtain a metal substrate with a closed through slot; the shape of the closed through slot is a triangular prism, and the cross-sectional shape of the closed through slot is a triangle; The base of the triangle is 2.5mm, the height is 2.5mm, and the two base angles α and β are both 63°; the metal substrate is an AZ31 magnesium alloy substrate with a thickness of 6mm, a length of 60mm, and a width of 60mm; wire-cut molybdenum wire The diameter is 0.2mm;

[0051] Step 2, adding reinforcing phase particles into the closed through groove of the metal substrate with closed through grooves obtained in step 1 to obtain a metal substrate to be processed; the reinforcing phase particles are hydroxyapatite, and the addition amount is 187.5 mm 3 ;

[0052] Step 3: Perform friction stir processing at the closed through groove of the metal su...

Embodiment 2

[0074] This embodiment includes the following steps:

[0075] Step 1, using wire cutting to open two closed through grooves inside the metal substrate to obtain a metal substrate with closed through grooves; the shape of the closed through grooves is a triangular prism, and the cross-sectional shape of the closed through grooves is a triangle; The base of the triangle is 2.5mm, the height is 2.5mm, and the two base angles α and β are both 63°; the metal substrate is an AZ31 magnesium alloy substrate with a thickness of 6mm, a length of 60mm, and a width of 60mm; wire-cut molybdenum wire The diameter is 0.1mm; the two closed through grooves are parallel to each other and the shortest distance between them is 10mm;

[0076] Step 2, adding reinforcing phase particles into the closed through groove of the metal substrate with closed through grooves obtained in step 1 to obtain the metal substrate to be processed; one of the reinforcing phase particles in the closed through groove ...

Embodiment 3

[0084] This embodiment includes the following steps:

[0085] Step 1, using wire cutting to open 4 closed through grooves inside the metal substrate to obtain a metal substrate with closed through grooves; the shape of the closed through grooves is a quadrangular prism, and the cross-sectional shape of the closed through grooves is a rectangle; The length of the rectangle is 2mm and the width is 2mm; the metal substrate is a TC4 titanium alloy substrate with a thickness of 6mm, a length of 600mm and a width of 60mm; the diameter of the wire-cut molybdenum wire is 0.1mm; parallel to each other and the shortest distance between them is 6mm;

[0086] Step 2, adding reinforcing phase particles to the closed through grooves of the metal substrate with closed through grooves obtained in step 1 to obtain a metal substrate to be processed; the reinforcing phase particles in the four closed through grooves are ZrO 2 and tricalcium phosphate and two kinds of reinforcement phase particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com