Sewage treatment system for nickel alloy preparation

A sewage treatment system and nickel alloy technology, which are applied in the fields of metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

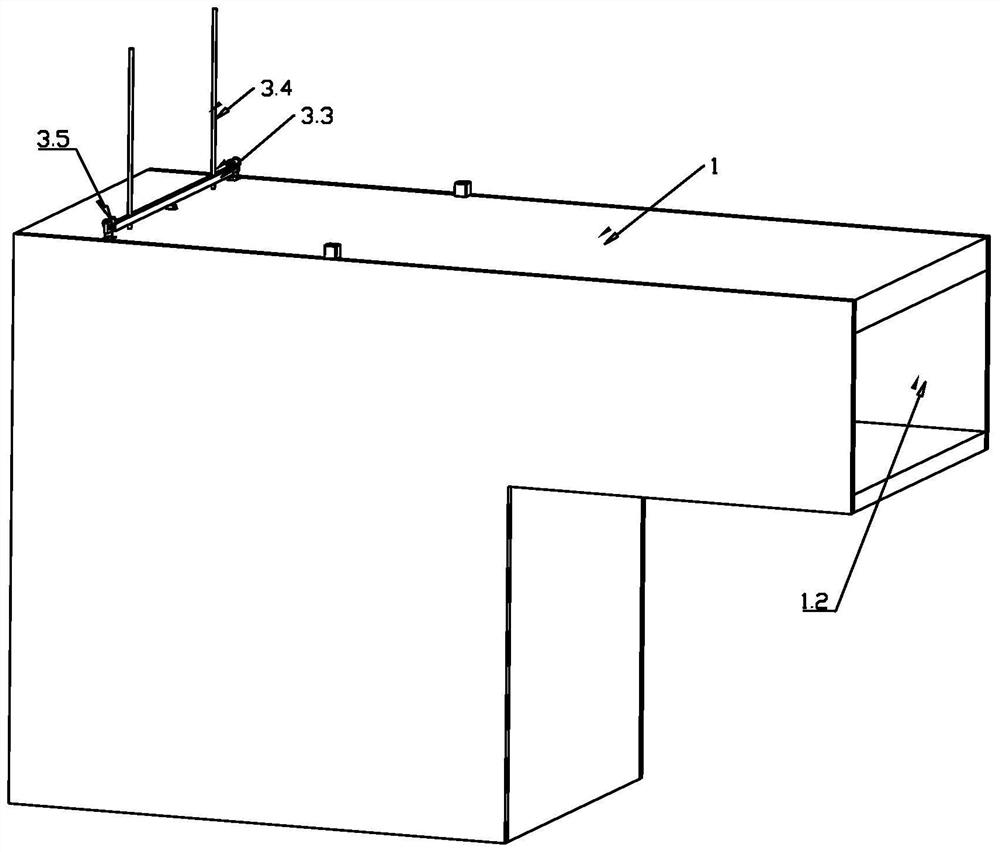

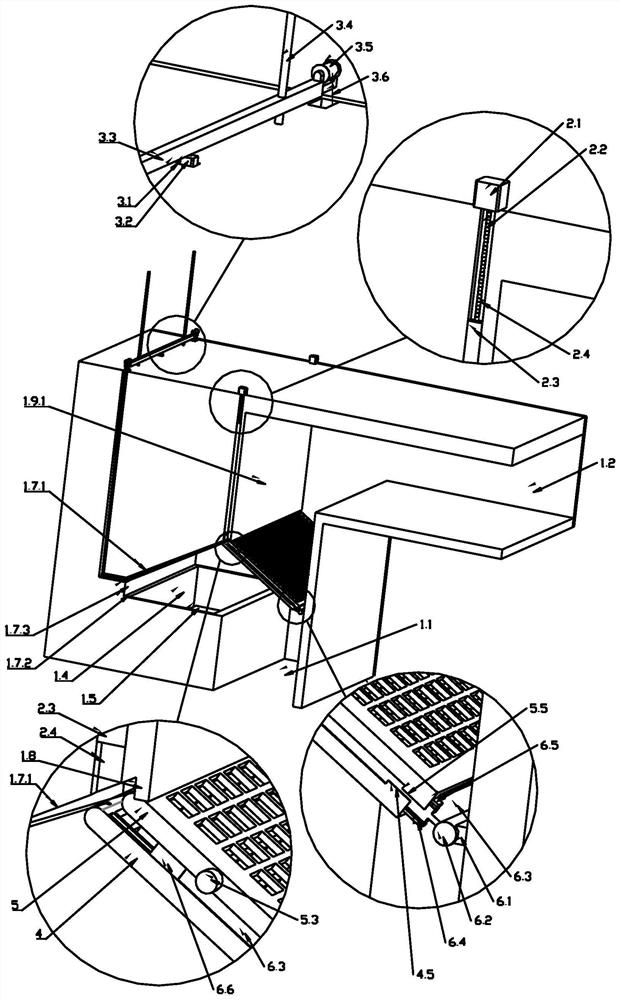

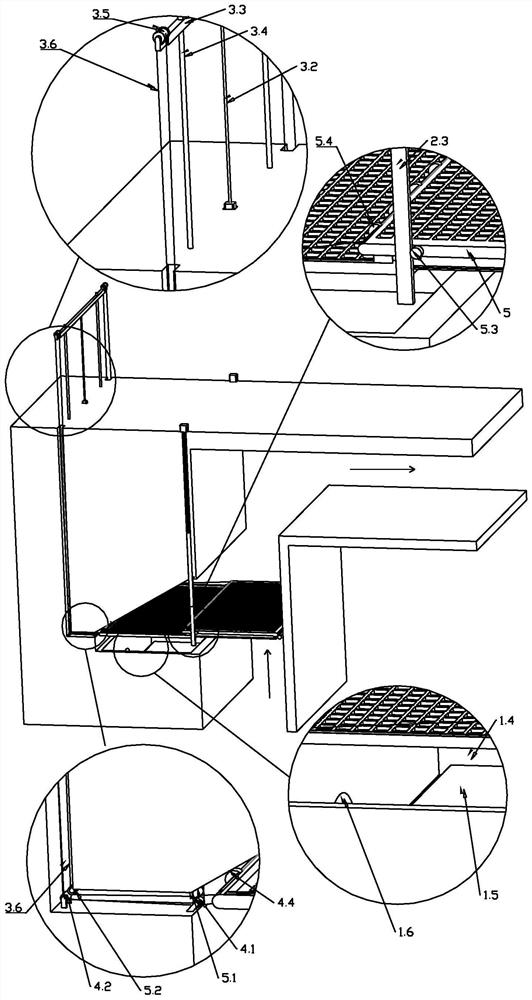

[0026] Reference numerals: 1 box body; 1.1 vertical channel; 1.2 horizontal channel; 1.4 second processing groove; 1.5 electromagnet adsorption unit; 1.6 processing channel; 1.7.1 top inclined wall; 1.7.2 bottom flat wall; 1.7. 3 side vertical wall; 1.8 strip baffle; 1.9.1 first side wall; 1.9.2 second side wall; 2.1 drive motor; 2.2 lead screw; 2.3 slide rod; 2.4 slide rod channel; 3.1 installation groove; 3.2 Hydraulic lifting rod; 3.3 Horizontal lifting rod; 3.4 Vertical guide rod; 3.5 Lifting pulley; 3.6 Pull rope; 4 The first adsorption plate; 4.1, 4.2 The first certain pulley; The first limit block; 5 the second adsorption plate; 5.1, 5.2 the second fixed pulley; 5.3 the second limit column; 5.4 the second roller; 5.5 the second limit block; ; 6.3 rectangular mounting frame; 6.4 first slide rail; 6.5 second slide rail; 6.6 end limit block.

[0027] As shown in the figure, a sewage treatment system for nickel alloy preparation includes a box body 1, wherein the box body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com