Conical concentric-square-shaped labyrinth structure supporting structure

A structural support and tapered technology, applied in gas/liquid distribution and storage, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of reduced cross-sectional area, difficult production and small volume of inner tanks, etc., to improve thermal insulation Insulation performance, reducing temperature gradient, increasing the effect of heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

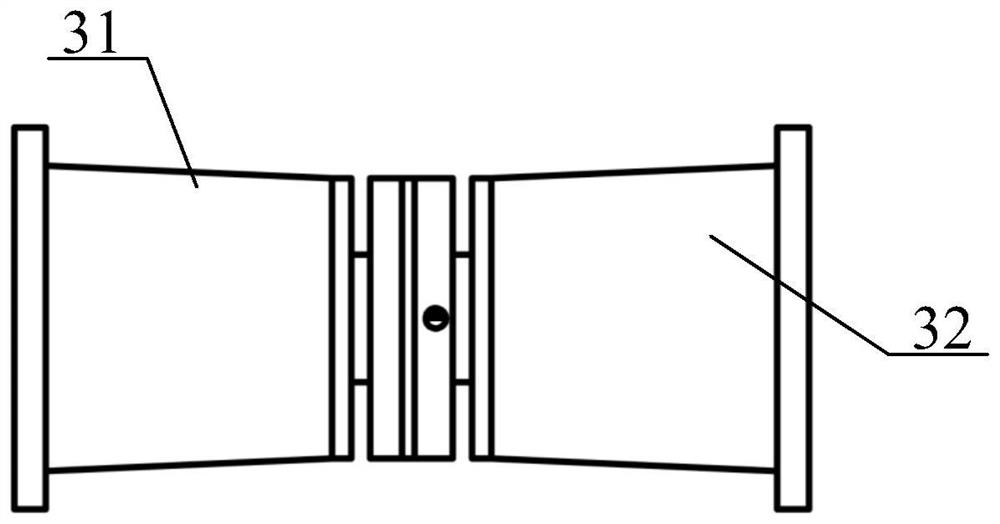

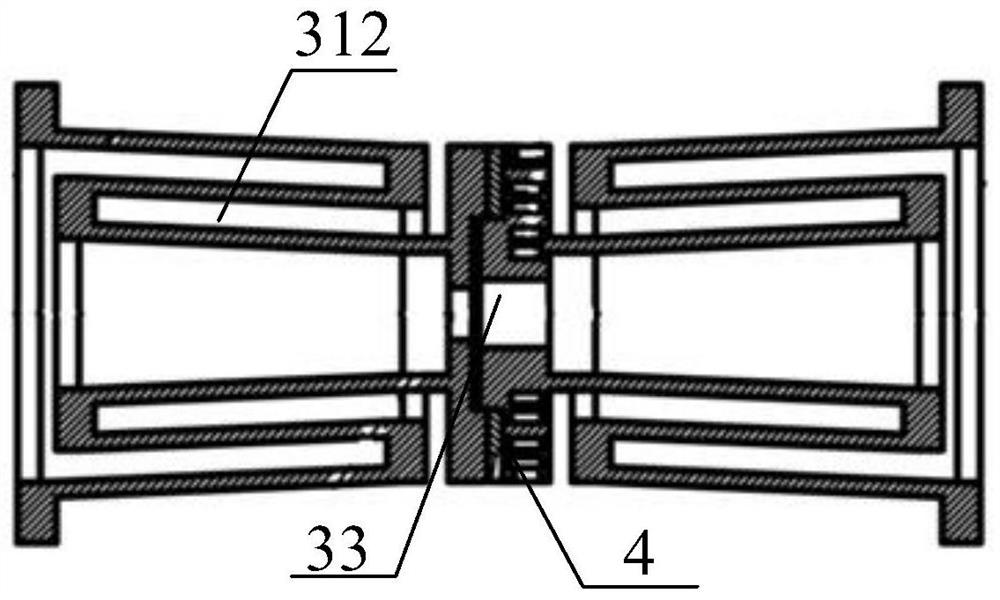

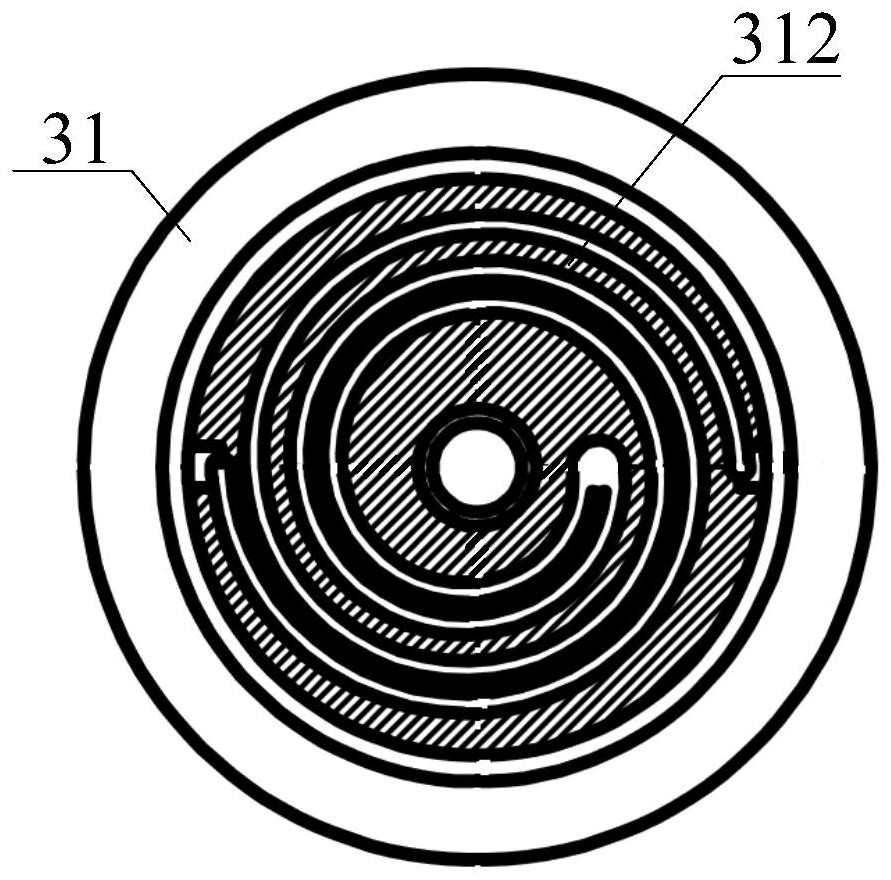

[0031] as attached figure 1 to the attached Figure 4 As shown, the present invention provides a conical labyrinth structure support structure, including an outer tank body 1 of a cryogenic liquefaction vessel, an inner tank body 2 of a cryogenic liquefaction vessel, a conical labyrinth support structure 3 and a thermal insulation pad 4, The tapered labyrinth support base structure 3 is embedded in both ends of the outer tank body 1 of the cryogenic liquefaction container and the inner tank body 2 of the cryogenic liquefaction container; the tapered labyrinth support seat structure 3 also includes: The left conical return labyrinth connection seat 31, the right conical return labyrinth connection seat 32 and the threaded hole 33; the left conical return labyrinth connection seat 31 and the right conical return labyrinth connection seat 32 The threaded holes 33 are opened at the inner middle position of the left conical labyrinth connection seat 31 and the right conical labyri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com