Industrial kiln detection method and device

A detection device and kiln technology, which is applied in the direction of measurement device, optical device, process efficiency improvement, etc., can solve the problems of difficulty in detection and measurement of charge surface, and achieve the effect of high contrast, accurate measurement data, and clear imaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

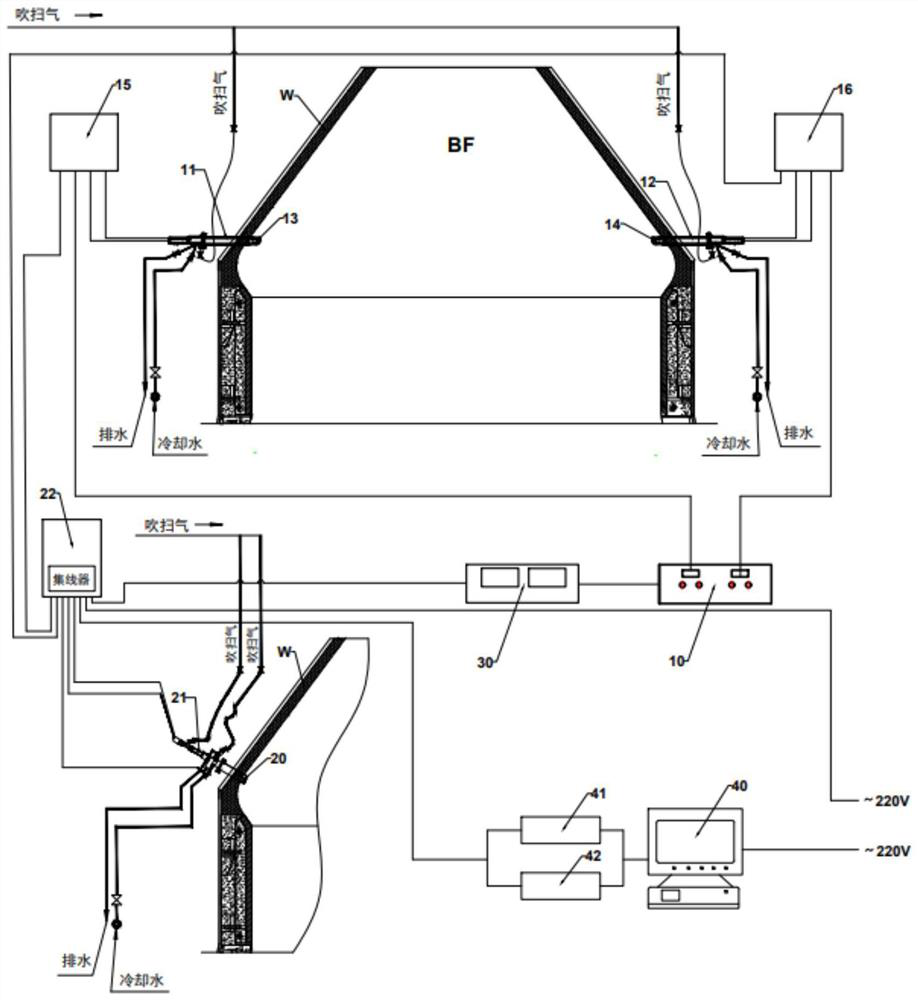

[0024] figure 1 The device for detecting the material level in a blast furnace according to the present invention is schematically shown. figure 1 The plug-in laser guns 11, 12 and the plug-in camera gun 21 respectively installed at different positions of the furnace wall W of the blast furnace BF are shown. The laser guns 11 and 12 and the camera gun 21 are usually also introduced with a purge air flow and a cooling water flow to clean and cool them to cope with the harsh environment of the blast furnace.

[0025] The arrangement of cooling water and purge gas of such a plug-in gun body is well known in the art, for example, refer to the applicant's previous related patent applications CN1505387A, CN1877249A, CN206438145U, CN206402324U, CN201540038U, etc., which are incorporated herein by reference. all content.

[0026] The front ends of the laser guns 11 and 12 extend into the furnace and are respectively equipped with emitting optical lens groups 13 and 14. The lasers ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com