Emergency charging type plasma forcible entry cutting machine circuit

An emergency charging and plasma technology, applied in plasma welding equipment, electrical components, adjusting electrical variables, etc., can solve problems such as low safety and inability to realize cutting, and achieve high safety, meet outdoor processing needs, and novel circuits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

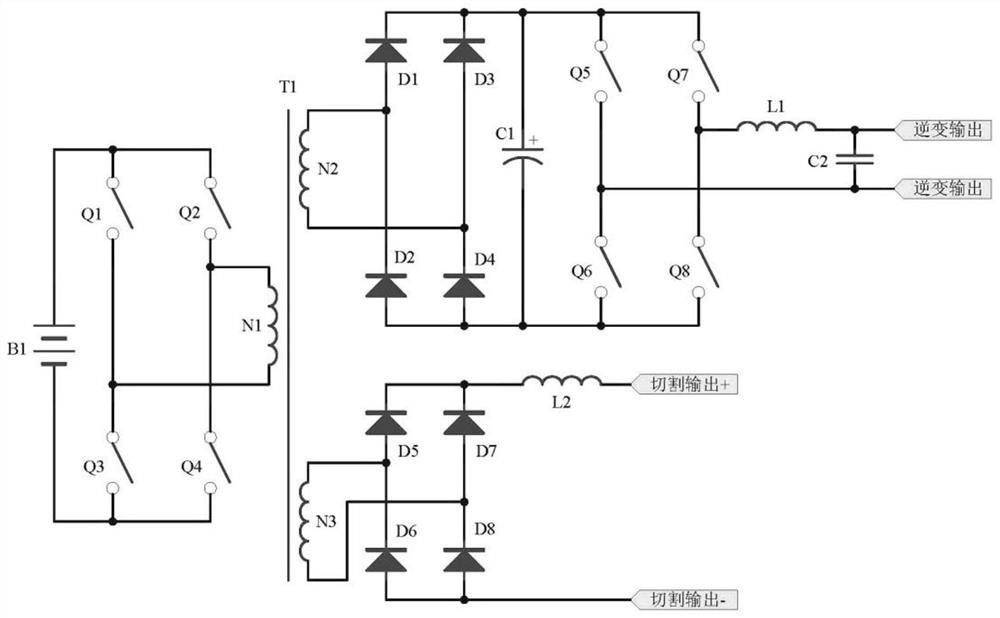

[0027] like figure 1 , an embodiment provided by the present invention: an emergency rechargeable plasma demolition and cutting machine circuit, the circuit includes a battery B1, a first full-bridge switch circuit, a transformer T1, a first full-bridge rectifier filter circuit, and a second full-bridge A switch circuit and a second full-bridge rectifier filter circuit, the positive and negative terminals of the battery B1 are connected to the primary coil N1 winding of the transformer T1 through the first full-bridge switch circuit, and the output end of the transformer T1 includes two secondary coil windings , N2 winding and N3 winding respectively, wherein, the N2 winding is connected to the first full-bridge rectifier filter circuit and the second full-bridge switch circuit in turn, and the output end of the second full-bridge switch circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com