Bed board, mattress and electric bed

A bed board and mattress technology, which is applied in the field of electric beds, can solve problems such as huge difference in mechanical properties, frictional noise at breaks, heavy overall structure, etc., and achieve the goals of improving bending resistance, good sound insulation and sound absorption performance, and improving support performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] like figure 1 As shown, a bed board corresponding to a preferred embodiment of the present invention includes a base plate 1 for supporting a human body, and the base plate 1 is made of a flexible porous material.

[0055]The microstructure of flexible porous materials has voids, and its flexibility is better than that of wooden boards. Specifically, its elastic strain range and plastic strain range are larger than the relevant parameters of wood (ie, less prone to fracture). Preferably, the impact toughness of the flexible porous material (the ability of the material to absorb plastic deformation work and fracture work under impact load) is greater than 200kJ / m 2 , which has reliable flexibility and fracture resistance. In addition, the structure of the porous material enables the substrate 1 to have good sound absorption and sound insulation properties, and it is not easy to generate noise during the deformation process, which has the effect of shock absorption and n...

Embodiment 2

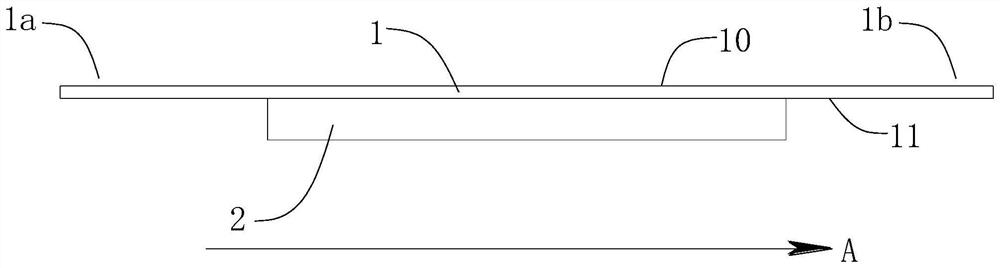

[0061] In this embodiment, refer to image 3 and Figure 4 , the reinforcing member is an elongated rib plate 2, and the base plate 1 includes a first surface 10 for carrying the human body and a second surface 11 away from the first surface 10. Usually, in use, the first surface 10 faces the human body. side (above), the second surface 11 faces the ground (below). In order to make the human body more comfortable when lying on the bed, the ribs 2 are arranged on the side of the second surface 11 , that is, supported under the base plate 1 , so that the first surface 10 of the base plate 1 is more flat.

[0062] In this embodiment, the rib plate 2 is an independent part from the base plate 1 , which can be connected to the second surface 11 of the base plate 1 by gluing or heat welding, and preferably, the rib plate 2 is perpendicular to the base plate 1 .

[0063] When the bed board is installed on the bed frame, its base plate 1 is supported at both ends (the first end 1a a...

Embodiment 3

[0071] In this embodiment, the reinforcing member is also the rib plate 2, and the difference from the second embodiment is that the rib plate 2 is a part of the base plate 1, refer to Figure 7 and Figure 8 , the rib plate 2 includes a connecting portion 20 connected to the base plate 1 and a first inclined surface 21, the base plate 1 is provided with a second inclined surface 13, the first inclined surface 21 and the second inclined surface 13 are fitted, preferably, the first inclined surface 21 and the first inclined surface 21 The inclination angles of the two inclined surfaces 13 are both 45°.

[0072] The rib plate 2 is made by cutting. Specifically, an I-shaped slit can be cut on the base plate 1 first. Refer to Figure 9 and Figure 10 , the I-shaped slit includes a first slit 150 and a second slit 151 that are parallel and a third slit 152 that is perpendicular to the first slit 150 and the second slit 151 . Then, the right-angle first groove 153 connecting the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com