Self-adjusting pipeline cleaning robot and cleaning method

A cleaning robot and self-adjusting technology, which is applied in the field of pipeline hygiene and safety, can solve the problems such as the difficulty of applying the range hood pipeline robot, the inability to complete the cleaning and disinfection work of the pipeline, and the difficulty of stable crawling of the vertical pipeline, so as to achieve a significant cleaning and disinfection effect and reduce bacteria. The effect of high degree of dissemination and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

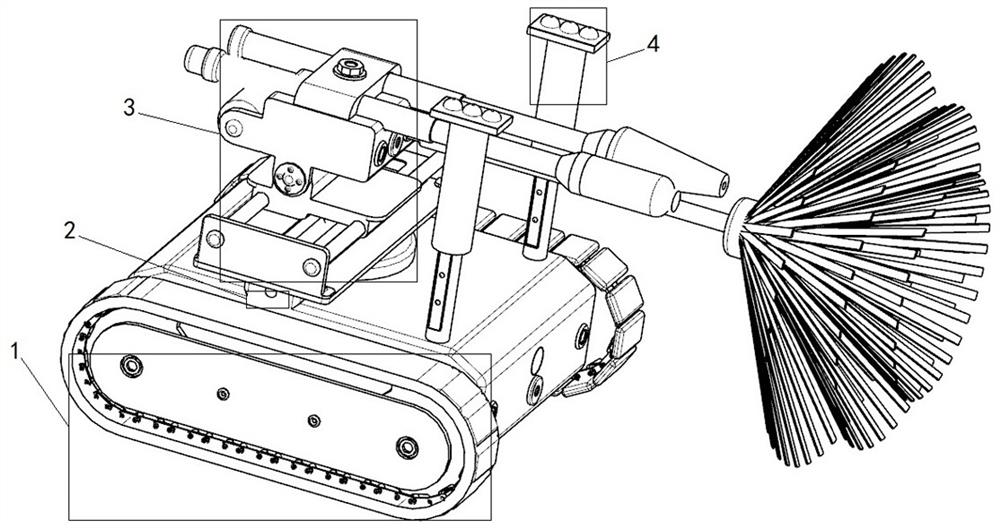

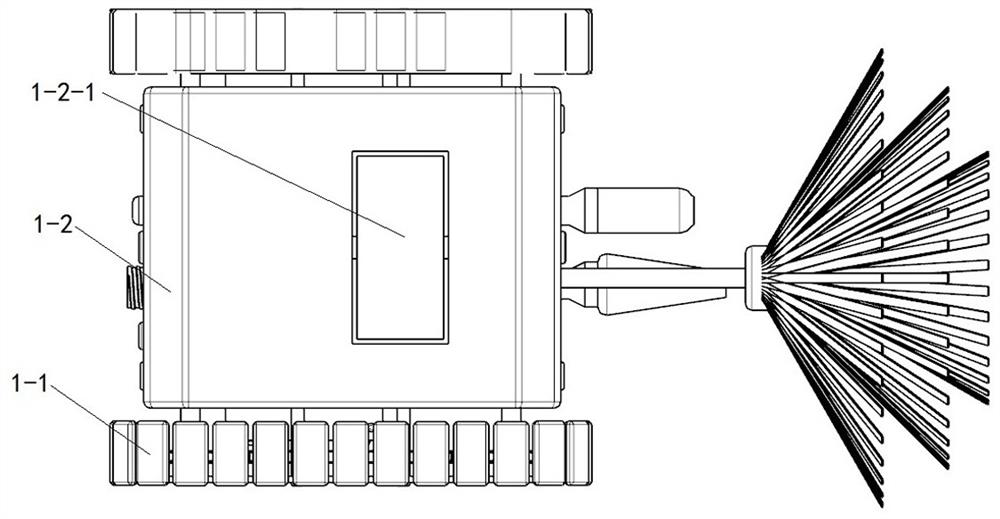

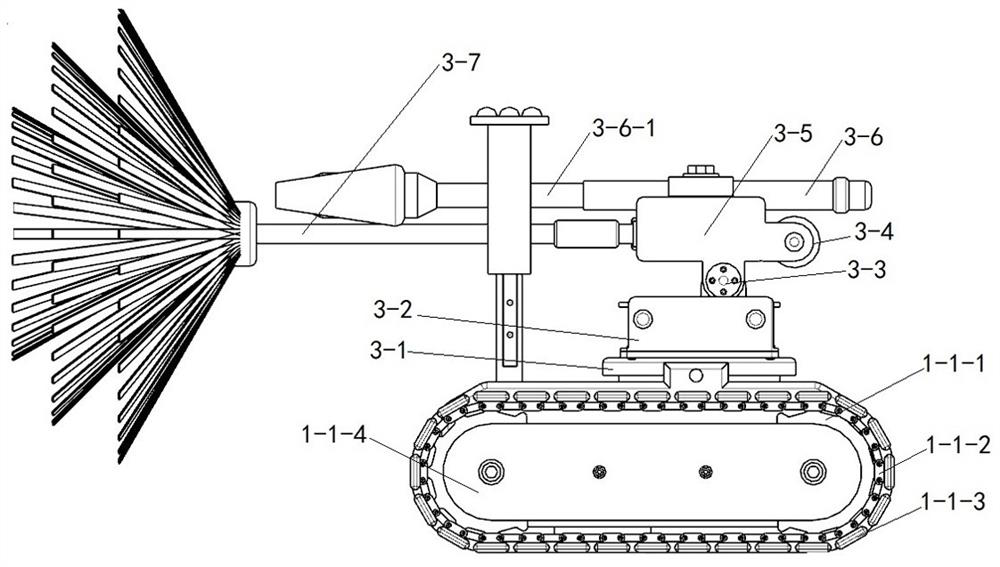

[0052] like Figure 1-19 The shown self-adjusting pipeline cleaning robot is used to improve the stability of the device walking in the pipeline, and is suitable for cleaning inclined pipelines, and even suitable for cleaning working conditions of vertical pipelines. The self-adjusting pipe cleaning robot can be flexibly applied to various pipe types such as square pipes and round pipes. The operator can set operation instructions in advance and execute them according to their own and environmental needs. Compared with other robots, the self-adjusting pipe cleaning robot has strong stability and good shock resistance, and can avoid the problem of device rollover caused by working vibration. At the same time, the crawler permanent magnet adsorption structure optimizes the running mechanism of the chassis, and the movement is flexible, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com