Composite cutter for machining guide pipe hole and seat ring chamfer of aluminum cylinder cover

A conduit hole and composite technology, which is applied in the field of composite cutters for aluminum cylinder head conduit hole and seat ring chamfering, can solve the problem of product quality coaxiality cannot be guaranteed, the cumulative error of secondary repeated positioning, engine cylinder head leakage Air and other problems, to achieve the effect of reducing product scrap loss, improving roundness, and reducing secondary clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

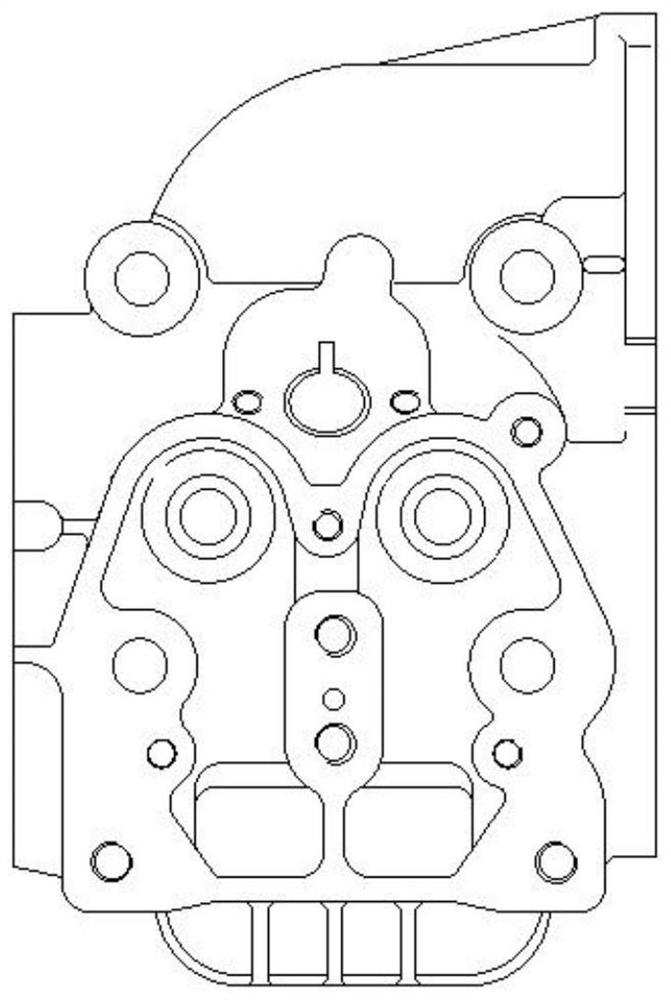

Image

Examples

Embodiment Construction

[0028] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

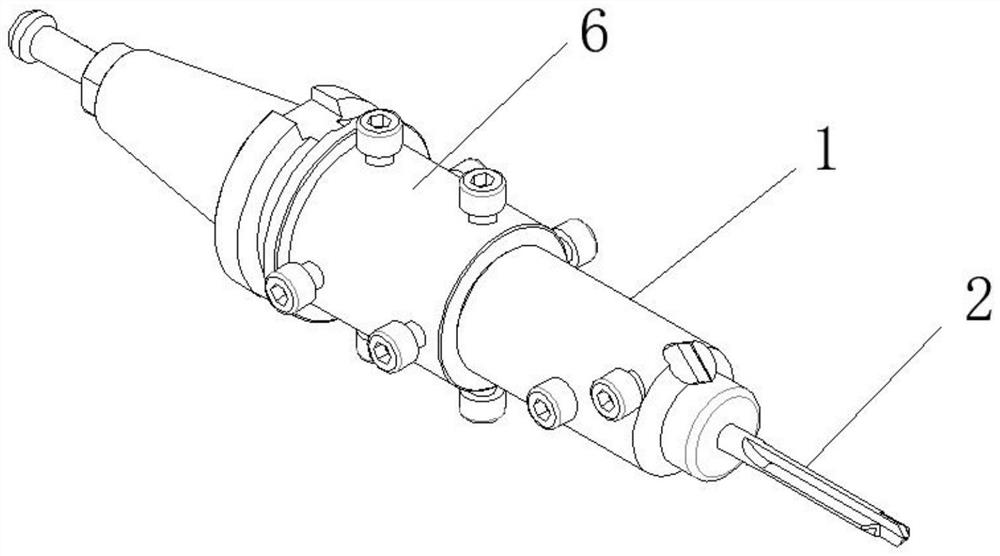

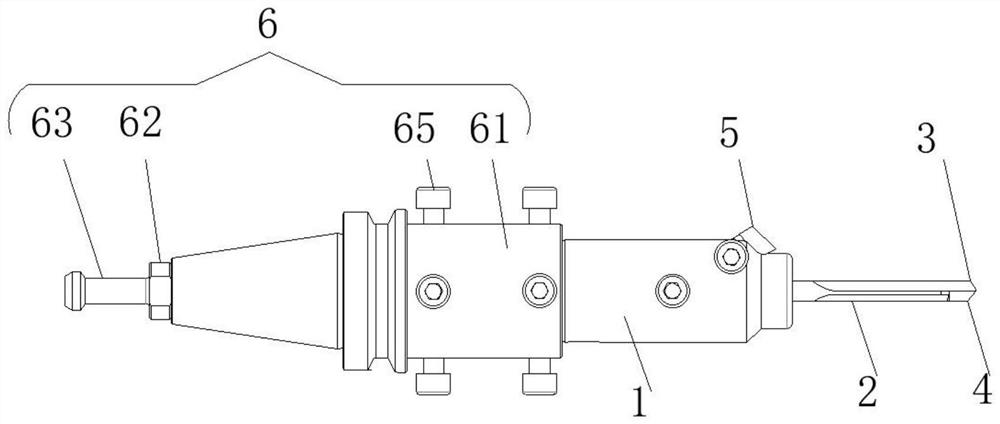

[0029] like figure 2 and image 3 As shown in the figure, a composite tool for chamfering a conduit hole of an aluminum cylinder head and a seat ring includes a main tool bar 1, and one end of the main tool bar 1 is provided with a fine boring and fine reaming compound tool 2. The fine boring and fine reaming compound tool 2. A fine boring cutter edge 3 and a fine reamer cutter edge 4 are respectively provided on both sides of one end away from the main cutter bar 1, and the lateral distance between the tool tip of the fine boring cutter edge 3 and the main cutter bar 1 is greater than that of the fine reamer cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com