High-frequency induction heating solidification device and method for preparing high-temperature alloy

A high-frequency induction heating and high-temperature alloy technology, which is applied in the field of high-frequency induction heating and solidification devices and electromagnetic induction heating and solidification devices, can solve problems such as coarse structure and element segregation, and achieve the goal of improving alloy structure, improving alloy performance, and reducing attenuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

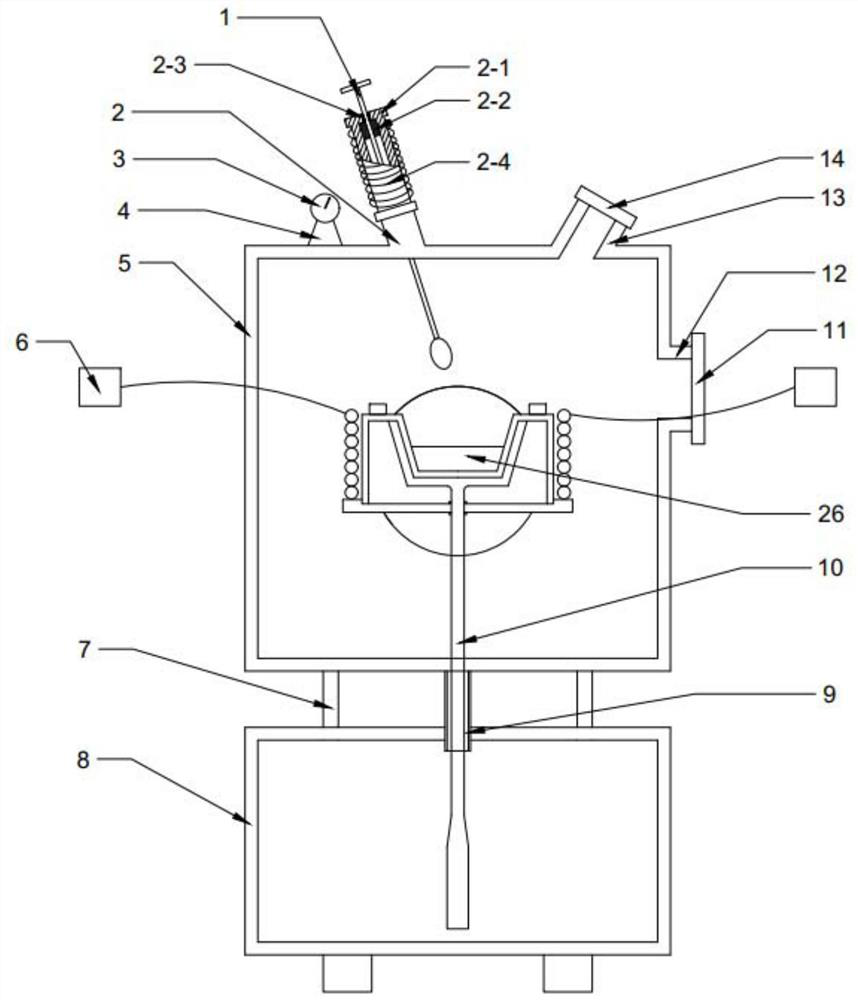

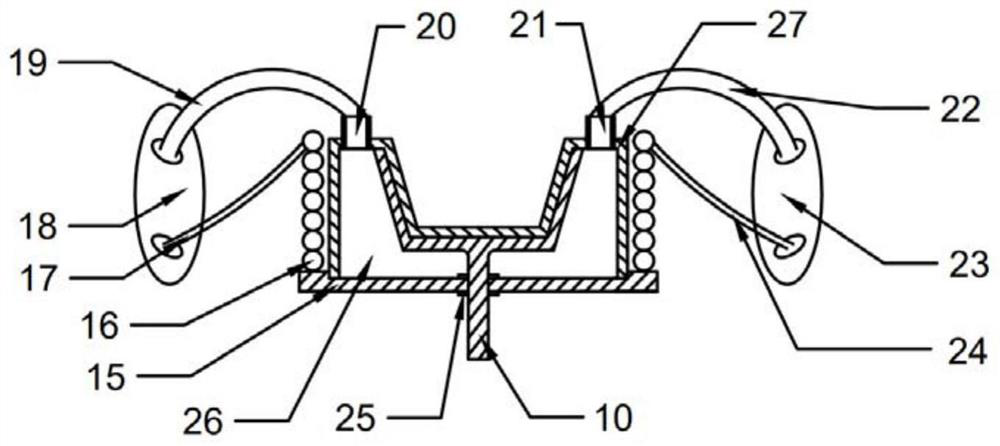

[0036] Embodiment 1: Combining figure 1 and figure 2Illustrating this embodiment, this embodiment includes a turning scoop 1, a scoop transmission mechanism 2, a pressure gauge 3, a pressure gauge base 4, a furnace body 5, a water-cooled copper crucible, a support rod 7, a stand assembly 8, and a transition rod welding 9, high-frequency vibrating rod 10, induction coil 16 and induction coil power supply 6; pressure gauge 3 is installed on the upper end face of furnace body 5 through pressure gauge base 4, and scoop transmission mechanism 2 is installed on the upper end face of furnace body 5 On the top, the turning scoop 1 is sealed and installed on the feeding scoop transmission mechanism 2, and the turning scoop 1 is lifted and rotated. The water-cooled copper crucible is partially installed inside the furnace body 5, and the water-cooled copper crucible is cooled by the upper water-cooling method. The stand assembly 8 is installed on the lower end face of the furnace body...

specific Embodiment approach 2

[0042] Specific implementation mode 2: Combining figure 1 Illustrating this embodiment, the scoop transmission mechanism 2 of this embodiment includes a casing 2-1, a rubber ring 2-2, a vacuum silica gel 2-3 and a bellows 2-4, and the turning spoon 1 passes through the rubber ring 2-2 Inside the shell 2-1, the bellows 2-4 is fitted on the shell 2-1, and the vacuum silica gel 2-3 is applied between the inlet part of the shell 2-1 and the turning spoon 1. This setting ensures tightness and lubricity, the bellows ensures the normal rotation of the turning spoon, the vacuum silicone allows the turning spoon to be freely stretched up and down, and the rubber ring provides frictional force so that the turning spoon is not under a certain external force, not under certain conditions. will slip. Other components and connection methods are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Specific implementation three: combination figure 2 Illustrating this embodiment, the water-cooled copper crucible of this embodiment includes a water-cooled copper crucible body 27, a water inlet pipe 19, a water outlet pipe 22, a water inlet port 20 and a water outlet port 21; the water inlet port 20 and the water outlet port 21 are installed on the water-cooled copper crucible body. On the upper end surface of 27 , one end of the water inlet pipe 19 and the water outlet pipe 22 are respectively connected with the water inlet port 20 and the water outlet port 21 . This arrangement is convenient to keep circulating cold water in the water-cooling tank in the water-cooled copper crucible. Since the water inlet and outlet are located at the upper part of the water-cooled copper crucible, the cold water will always be filled in the water-cooled copper crucible, which is convenient for water-cooling the crucible. , and other components and connection methods are the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com