Electrochemical polishing method capable of realizing single-phase solid solution high-entropy alloy

A high-entropy alloy and electrochemical technology, applied in the field of electrochemistry, can solve the problems of lack of systematicness and guidance, and achieve the effect of huge application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

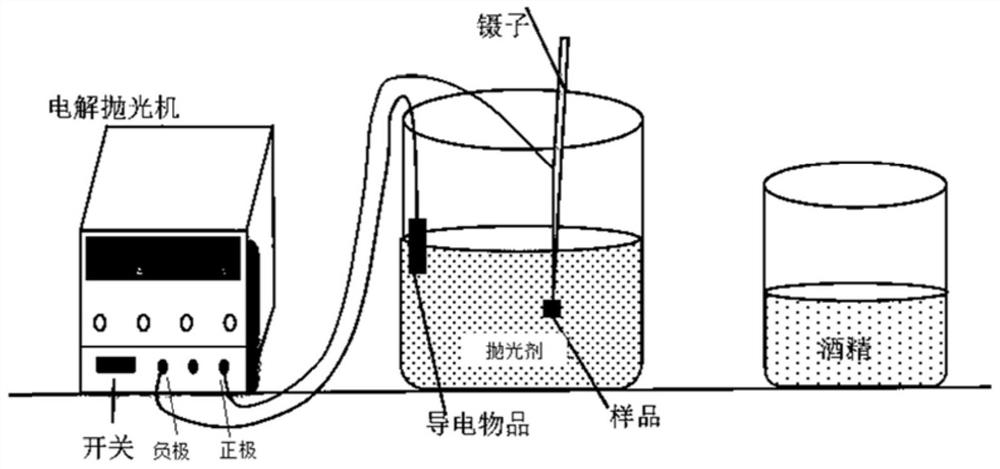

Method used

Image

Examples

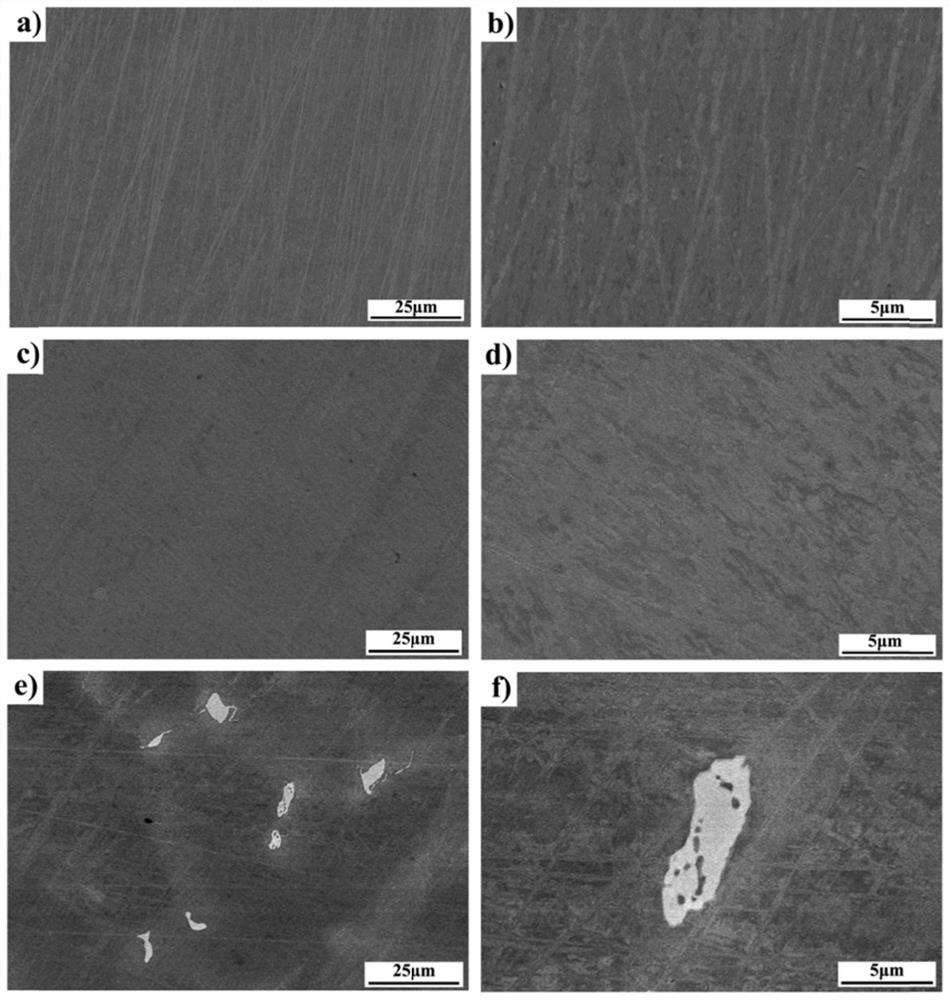

Embodiment 1

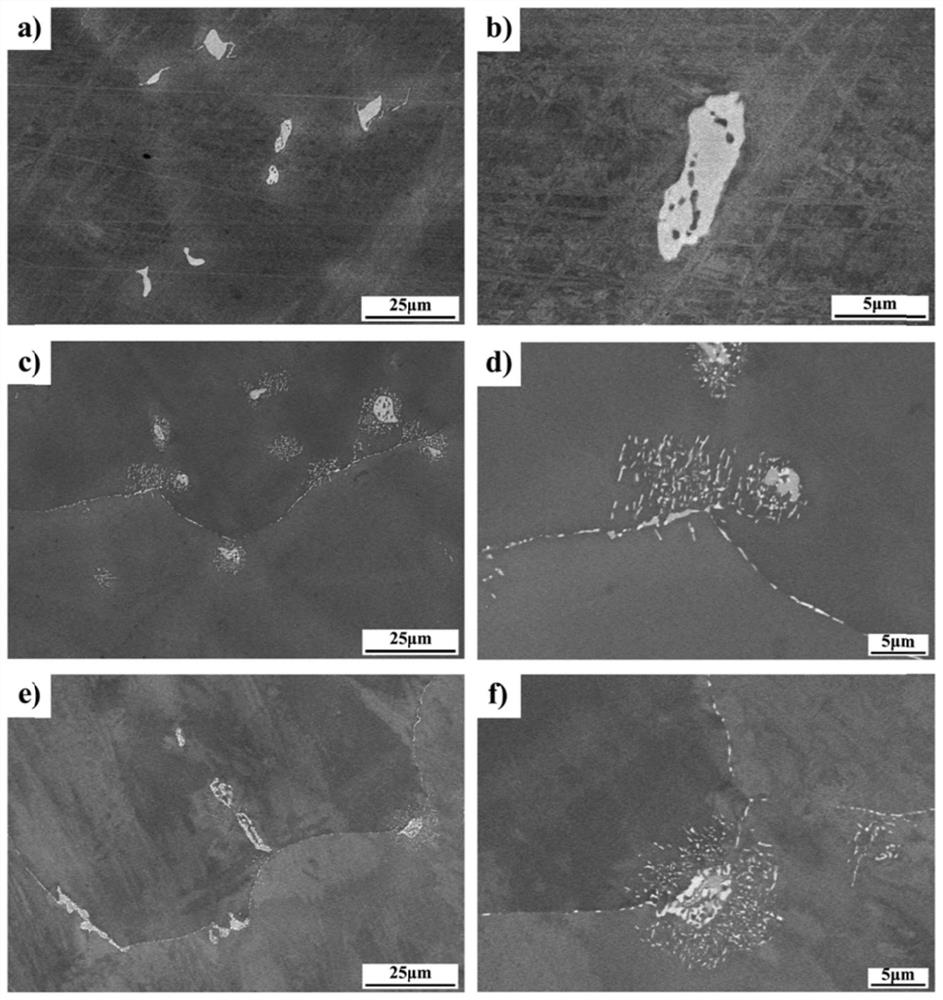

[0031] 1) Weigh the Mo blocks, Co blocks, Cr blocks, Fe blocks, and Ni blocks with a purity of 99.99%, wash them and then melt and solidify them in an electric arc furnace to prepare FeCoCrNiMo with different Mo contents. X Alloys (x=0, 0.1, 0.3) are finally cut into round bars of Φ3×3.7mm, which are recorded as samples Mo0, Mo0.1, and Mo0.3.

[0032] 2) Use 1500-mesh sandpaper to grind off the cut marks on the round bar obtained in step 1) and clean it, and then put all the test materials such as pyrophyllite in a blast drying oven to dry for later use.

[0033] 3) Take two samples of Mo0.3 after drying in step 2), and pressurize them to 4GPa and 7GPa respectively in a high-temperature and high-pressure press at a temperature of 1700°C to obtain samples 4GPaMo0.3 and 7GPaMo0.3.

[0034] 4) According to the volume ratio of perchloric acid: alcohol = 1:15, configure the polishing agent.

[0035] 5) Take the samples Mo0, Mo0.1, Mo0.3, 4GPaMo0.3 and 7GPaMo0.3 and immerse them in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com