Multilayer radon-reducing covering material and application thereof, and method for reducing radon exhalation rate of waste rock heap of uranium mine

A technology of covering materials and waste rock piles is applied in the field of decommissioning and treatment of nuclear facilities, which can solve the problems of low radon reduction rate, and achieve the effects of reducing gamma radiation dose, reducing radon precipitation rate, and facilitating vegetation restoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

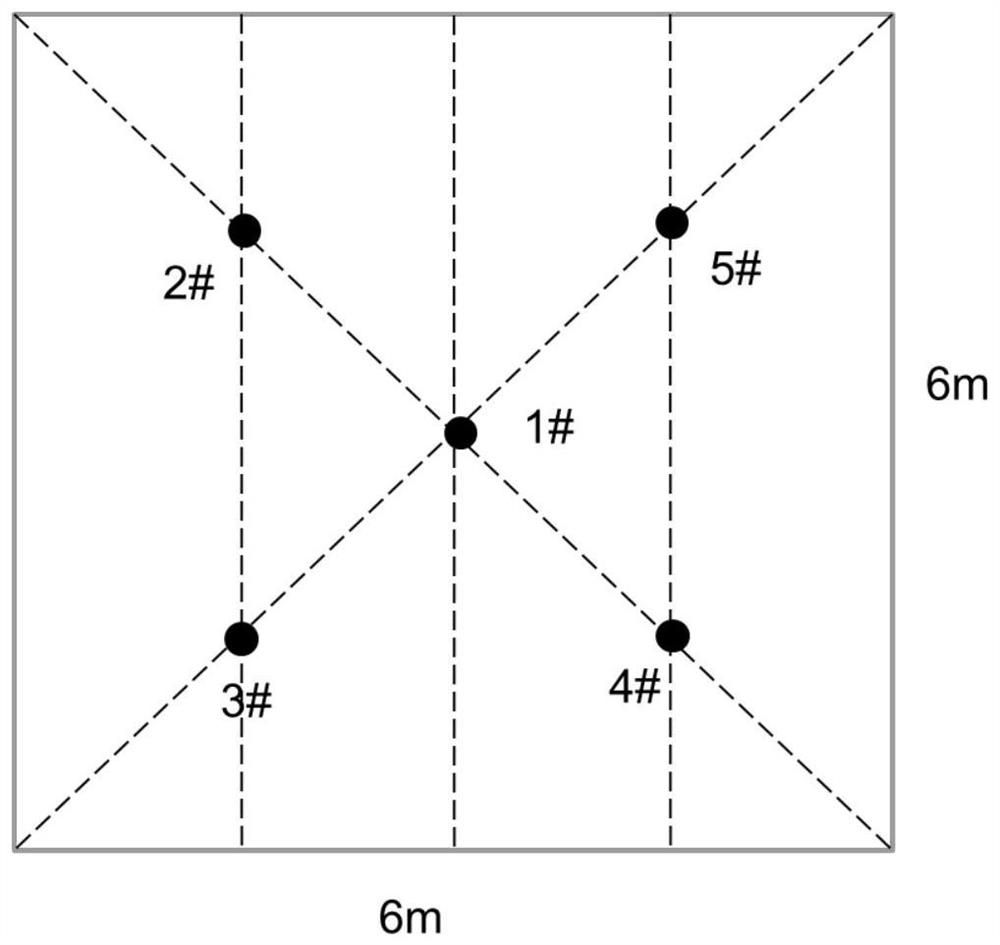

Method used

Image

Examples

Embodiment 1

[0041] The surface of the uranium mine waste rock pile is covered with bentonite in turn and compacted to obtain a bentonite layer with a thickness of 4 cm and a compaction degree of 10%;

[0042] The surface of the bentonite layer is covered with loess and then compacted to obtain the first loess layer with a thickness of 13 cm and a compaction degree of 10%;

[0043] The surface of the first loess layer is covered with loess and then compacted to obtain a second loess layer with a thickness of 18 cm and a compaction degree of 10%;

[0044] Among them, the loess was collected from the soil source of Shahuqiao, Nanjing Town, Quannan County, Ganzhou City, Jiangxi Province, and the radon precipitation rate of the loess was 0.01-0.29Bq / (m 2 s), the gamma radiation dose rate is (21.7~25.4)×10 -8 Gy / h; the radon precipitation rate of bentonite is 0.02~0.12Bq / (m 2 s), the gamma radiation dose rate is (24.6~29.3)×10 -8 Gy / h.

Embodiment 2~10

[0046] According to the method of Example 1, the surface of the uranium mine waste rock pile was covered with a covering material. The compositions of the covering materials in Examples 2 to 9 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com