Biomass raw material uniform feeding device

A biomass raw material and feeding device technology, which is applied in the fields of biofuel, fuel supply, block/powder fuel preparation, etc. The effect of improving combustion quality and efficiency, avoiding clogging, and improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

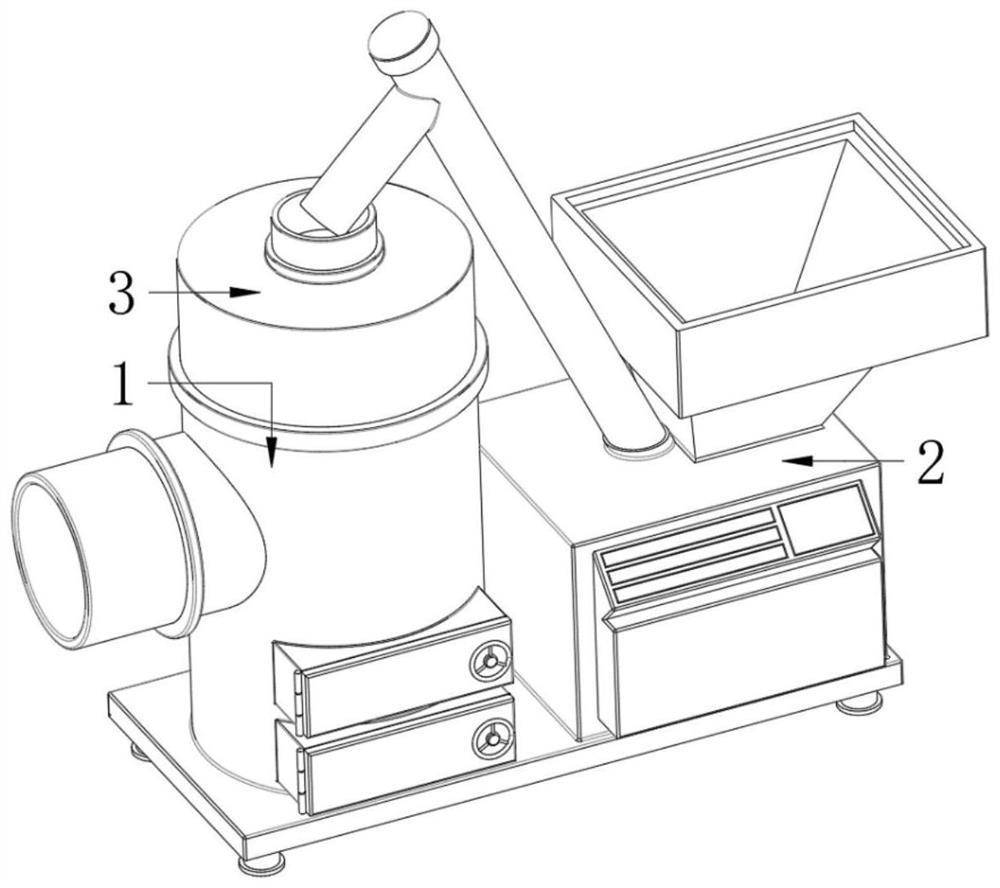

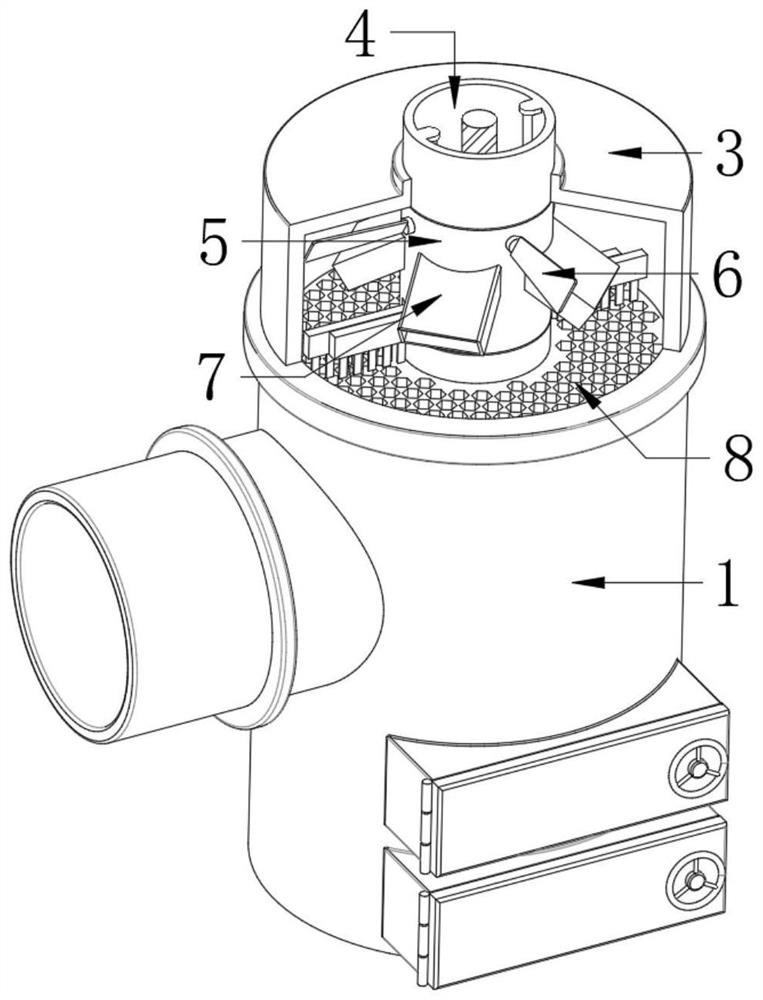

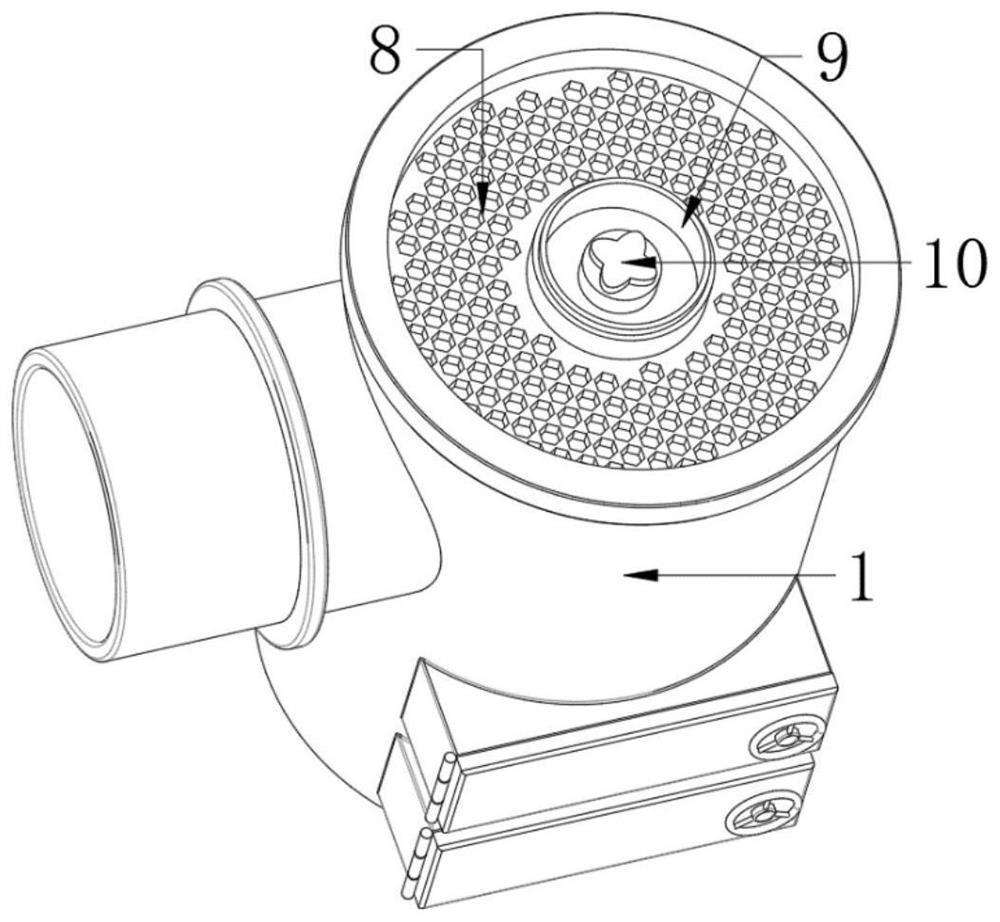

[0026] refer to Figure 1-6 , a biomass raw material uniform feeding device, including a combustion device 1 and a feeding device 2, the feeding device 2 is installed on one side of the combustion device 1, the upper side of the combustion device 1 is fixedly installed with a device shell 3, and the center of the device shell 3 A feed inlet pipe 4 is fixedly installed on the upper side, and a sub-screen plate 8 located in the device casing 3 is installed on the upper side of the combustion equipment 1. The interior of the device casing 3 is communicated with the interior of the combustion device 1, and the sub-screen plate 8 is evenly opened. There are several sieve openings. By using the biomass raw material uniform feeding device, the feeding device 2 can evenly pour the biomass fuel into the combustion device 1, so that the biomass fuel is burned more thor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com