Psicose centrifugal crystal drying device

A drying device and the technology of allulose, which is applied in the field of allulose centrifugal crystal drying device, can solve the problems that materials are easy to form aggregation, unfavorable materials are fully dispersed, and the drying effect is not ideal, so as to improve the drying effect. Sufficiency and drying effect, promoting toggle effect, drying effect enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

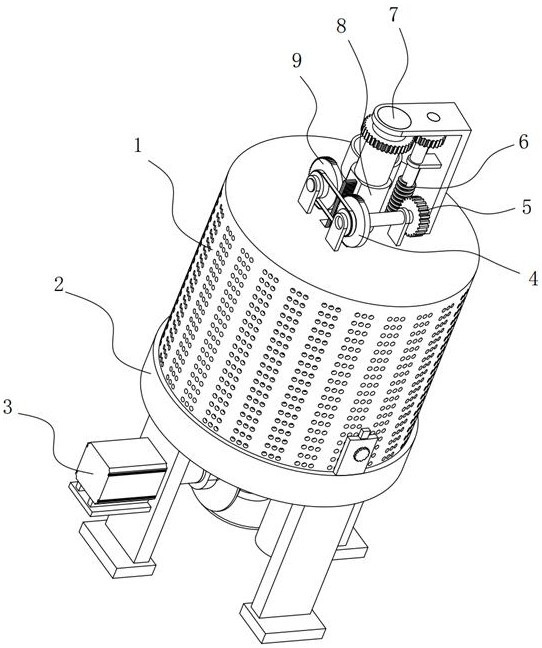

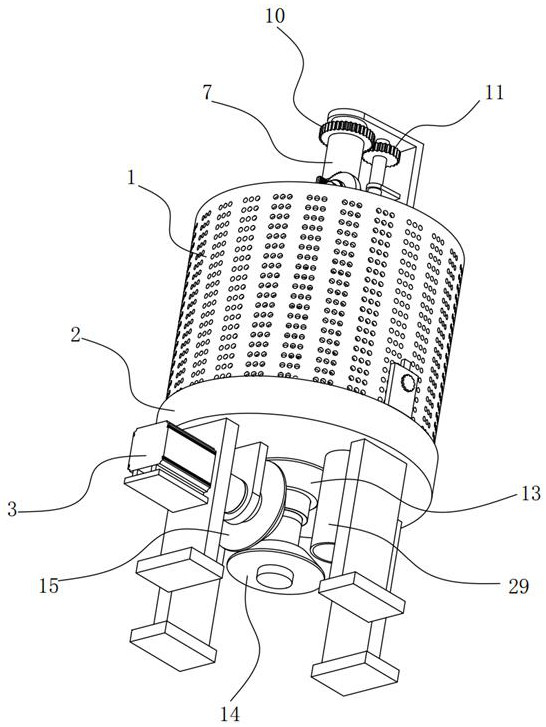

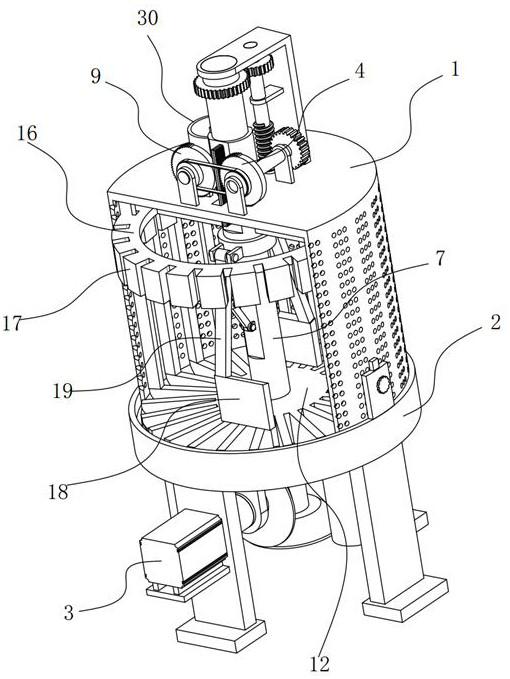

[0028] see Figure 1-7 , a psicose centrifugal crystal drying device, the device is placed in a dry environment, which specifically includes a limit collar 2, a heating chassis 12 is rotatably installed in the limit collar 2, and the heating chassis 12 is fixed on the There is a mesh bucket 1, the top of the mesh bucket 1 is provided with a mesh hole for air circulation, a feed pipe 30 is installed on the top of the mesh bucket 1, and a discharge pipe 29 connected to the mesh bucket 1 is installed at the bottom of the heating chassis 12. A central shaft 7 is rotatably installed, a rotating sleeve 8 is slidably sleeved on the central shaft 7, a rotating ring 28 is rotatably installed on the rotating sleeve 8, and a pair of swing rods 19 are hinged on the rotating sleeve 8, and the swing rod 19 is connected to the central shaft. A support rod 22 is hinged between 7 , and a dial 18 is fixed at one end of each swing rod 19 away from the rotating ring 28 .

[0029] The psicose cry...

Embodiment 2

[0036] see Figure 1-7 , On the basis of Embodiment 1, in addition, the guide assembly includes a number of evenly distributed partitions 27 fixed on the heating chassis 12, the partitions 27 extend along the radial direction of the heating chassis 12, and two adjacent partitions 27 There are arc grooves 26 between them, and the arc grooves 26 are opened on the heating chassis 12 . The partition plates 27 are arranged in a one-to-one correspondence with the rib plates 20 , and a distribution groove 21 is formed between two adjacent rib plates 20 .

[0037] The psicose crystals are dispersed along the arc groove 26, and during the rotation of the heating chassis 12, the psicose crystals slide along the arc groove 26 under the action of centrifugal force and enter the distribution groove 21 for upward climbing. At this time, the psicose crystals can be uniformly dispersed and placed in the distribution tank 21 under the action of centrifugal force, which greatly improves the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com