Tantalum capacitor automatic detection device

An automatic detection device, tantalum capacitor technology, applied in the direction of measurement device, capacitor test, measurement device shell, etc., can solve the problems of time-consuming, laborious, low efficiency, etc., to prevent damage, reduce burden, and facilitate compact layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

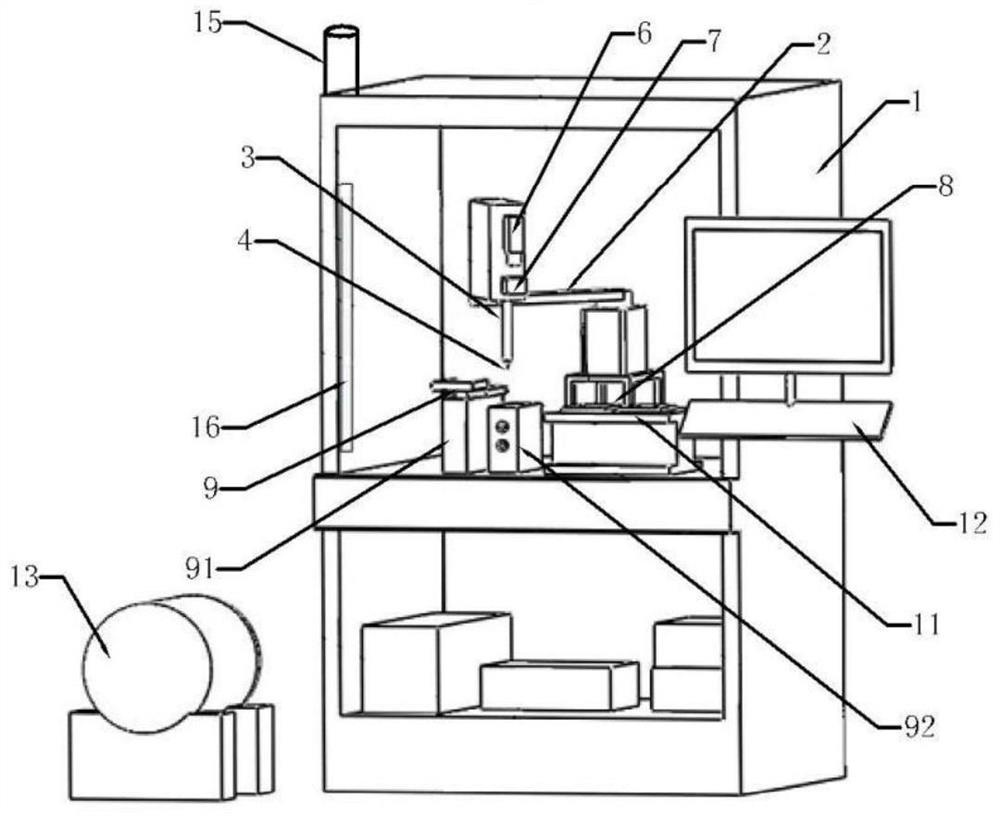

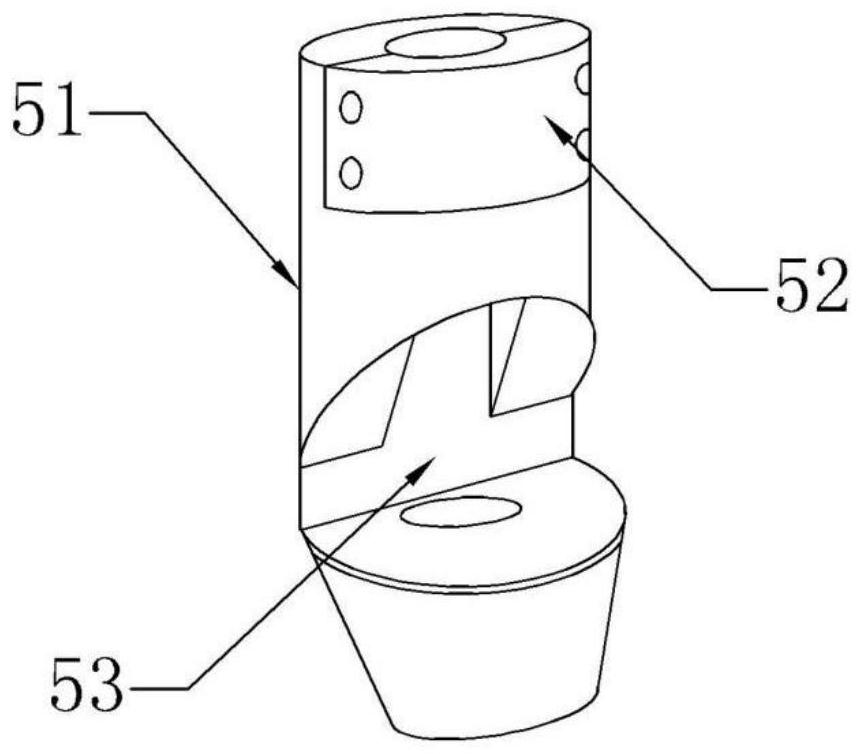

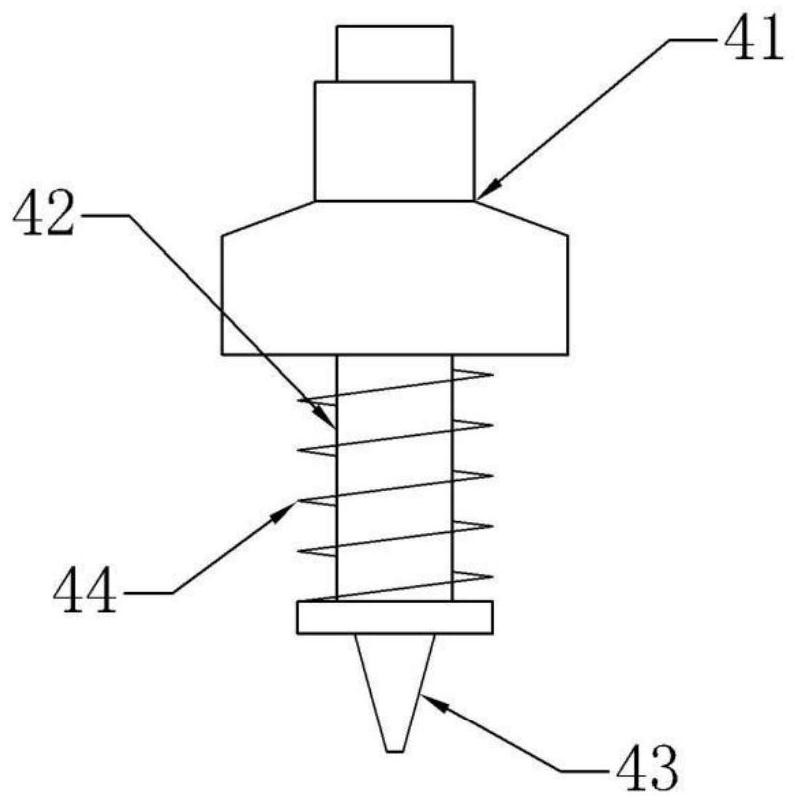

[0033] like Figure 1-7 As shown, an automatic detection device for tantalum capacitors includes a frame 1, a manipulator 2, a lifting mechanism 3, a suction nozzle 4, a suction nozzle fixing bracket 5, an industrial camera 6, a light source 7, a test table 8, a feeding tray 9, a feeding trough 10. Discharge tray 11, controller 12, negative pressure source 13, vacuum gauge 14 and alarm 15; the manipulator 2, lifting mechanism 3, industrial camera 6, light source 7, negative pressure source 13, testing instrument, feeding tray 9. The vacuum gauge 14 and the alarm 15 are electrically connected to the controller 12 .

[0034]The rack 1 has a double-layer cabinet structure with an open front. The feeding tray 9 , the manipulator 2 , the test table 8 and the unloading tray 11 are sequentially installed on the upper table of the rack 1 . The manipulator 2 includes a primary mechanical arm 21, a secondary mechanical arm 22, a primary driving member 23 and a secondary driving member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com